Yielding refers to the act of giving way, whether in physical materials under stress or in decision-making situations. Understanding the concept of yielding can enhance your ability to predict structural failure or improve conflict resolution strategies. Explore the rest of the article to learn how yielding impacts different fields and your daily life.

Table of Comparison

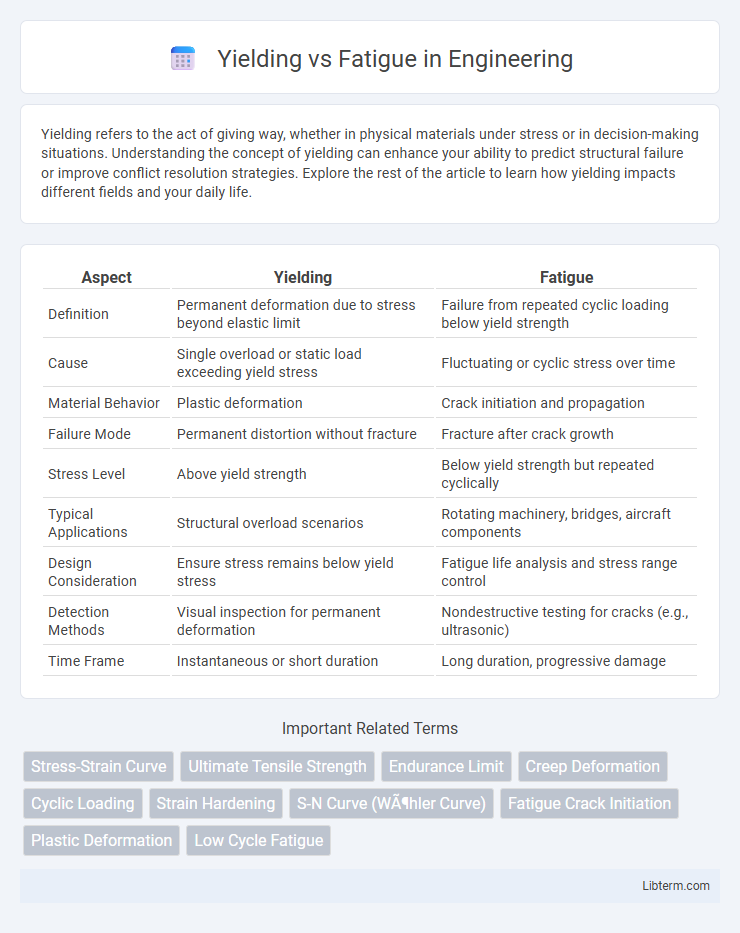

| Aspect | Yielding | Fatigue |

|---|---|---|

| Definition | Permanent deformation due to stress beyond elastic limit | Failure from repeated cyclic loading below yield strength |

| Cause | Single overload or static load exceeding yield stress | Fluctuating or cyclic stress over time |

| Material Behavior | Plastic deformation | Crack initiation and propagation |

| Failure Mode | Permanent distortion without fracture | Fracture after crack growth |

| Stress Level | Above yield strength | Below yield strength but repeated cyclically |

| Typical Applications | Structural overload scenarios | Rotating machinery, bridges, aircraft components |

| Design Consideration | Ensure stress remains below yield stress | Fatigue life analysis and stress range control |

| Detection Methods | Visual inspection for permanent deformation | Nondestructive testing for cracks (e.g., ultrasonic) |

| Time Frame | Instantaneous or short duration | Long duration, progressive damage |

Introduction to Yielding and Fatigue

Yielding refers to the permanent deformation of a material under stress when the applied load exceeds its yield strength, marking the onset of plastic behavior. Fatigue involves the progressive and localized structural damage occurring in materials subjected to cyclic loading, even below the yield strength. Understanding the mechanisms of yielding and fatigue is crucial for predicting material failure and ensuring structural integrity in engineering applications.

Defining Yielding in Materials

Yielding in materials refers to the point at which a material undergoes permanent deformation under applied stress, marking the transition from elastic to plastic behavior. It is characterized by the yield strength, the specific stress level at which materials begin to deform plastically without an increase in load. Understanding yielding is crucial for designing components to prevent structural failure by ensuring stresses remain below the yield point during service.

Understanding Fatigue Failure

Fatigue failure occurs when a material experiences repeated cyclic stresses below its yield strength, leading to the initiation and growth of cracks over time. Unlike yielding, which is a permanent deformation caused by a single application of stress exceeding the yield point, fatigue failure results from accumulated damage due to fluctuating loads. Understanding fatigue failure involves analyzing stress concentration, material properties, and the number of load cycles to predict the lifespan and prevent unexpected structural breakdowns.

Key Differences Between Yielding and Fatigue

Yielding refers to the permanent deformation of a material when stress surpasses its elastic limit, typically occurring in a single loading event. Fatigue involves the progressive and localized structural damage that occurs when a material is subjected to cyclic loading below its yield strength over time. Key differences include that yielding causes immediate plastic deformation, whereas fatigue leads to failure through crack initiation and growth after repeated stress cycles.

Mechanisms Leading to Yielding

Yielding occurs when a material undergoes plastic deformation due to applied stress exceeding its yield strength, primarily driven by dislocation movement and slip mechanisms within the crystal lattice. Microstructural changes such as the multiplication and interaction of dislocations weaken atomic bonds, facilitating permanent deformation. This contrasts with fatigue, where cyclic loading causes crack initiation and propagation over time rather than immediate plastic flow.

Mechanisms Behind Fatigue Failure

Fatigue failure occurs due to the initiation and propagation of cracks under cyclic loading, which differs from yielding where permanent deformation happens once the material's stress limit is exceeded. The primary mechanism behind fatigue failure involves microstructural changes such as slip band formation, crack nucleation at stress concentrators, and gradual crack growth leading to sudden fracture. Unlike yielding, fatigue damage accumulates over time even at stress levels below the material's yield strength, making crack propagation the critical factor in fatigue failure.

Factors Influencing Yielding and Fatigue

Material microstructure, loading conditions, and environmental factors critically influence yielding and fatigue behavior in metals. Yielding primarily depends on stress magnitude and temperature, dictating permanent deformation initiation, while fatigue is governed by cyclic stress amplitude, frequency, and surface defects that accelerate crack propagation. Grain size, alloy composition, and residual stresses also play pivotal roles in determining the material's resistance to both yielding and fatigue failure.

Real-World Examples of Yielding and Fatigue

Yielding occurs when a structural material deforms permanently under a single, excessive load, such as a steel beam bending under a heavy weight during construction. Fatigue involves material failure after repeated cyclic loading, exemplified by airplane wings developing cracks after numerous takeoff and landing cycles. Real-world cases include bridge components that yield during extreme stress events and aircraft fuselage panels that fail due to fatigue from constant vibration and stress cycles.

Prevention and Mitigation Strategies

Effective prevention and mitigation of yielding and fatigue in materials involve selecting appropriate alloys with high fatigue strength and applying surface treatments such as shot peening to reduce stress concentrations. Implementing design optimization techniques, including fillet radii and load distribution, minimizes localized stress and delays crack initiation. Regular maintenance inspections and non-destructive testing methods like ultrasonic or magnetic particle inspection ensure early detection and repair of fatigue cracks before catastrophic failure occurs.

Conclusion: Yielding vs Fatigue

Yielding occurs when a material deforms plastically under a single application of stress, marking the transition from elastic to permanent deformation. Fatigue involves the initiation and growth of cracks due to repeated cyclic stresses below the yield strength, ultimately leading to failure after numerous cycles. Understanding the distinct mechanisms and stress thresholds of yielding versus fatigue is crucial for designing components that ensure structural integrity and prevent unexpected failure.

Yielding Infographic

libterm.com

libterm.com