Thermal efficiency measures how effectively a system converts heat energy into useful work or output, indicating the performance of engines, heaters, and power plants. Higher thermal efficiency means less energy waste, which saves costs and reduces environmental impact. Explore the rest of the article to learn how improving thermal efficiency can benefit your energy use and sustainability goals.

Table of Comparison

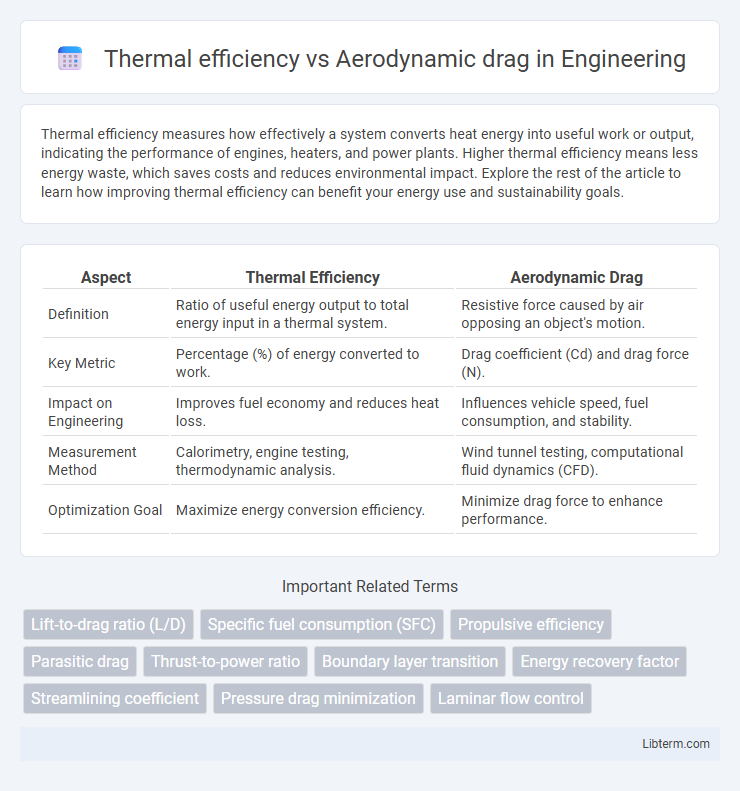

| Aspect | Thermal Efficiency | Aerodynamic Drag |

|---|---|---|

| Definition | Ratio of useful energy output to total energy input in a thermal system. | Resistive force caused by air opposing an object's motion. |

| Key Metric | Percentage (%) of energy converted to work. | Drag coefficient (Cd) and drag force (N). |

| Impact on Engineering | Improves fuel economy and reduces heat loss. | Influences vehicle speed, fuel consumption, and stability. |

| Measurement Method | Calorimetry, engine testing, thermodynamic analysis. | Wind tunnel testing, computational fluid dynamics (CFD). |

| Optimization Goal | Maximize energy conversion efficiency. | Minimize drag force to enhance performance. |

Introduction to Thermal Efficiency and Aerodynamic Drag

Thermal efficiency measures the effectiveness of converting fuel energy into useful work, often expressed as a percentage reflecting energy utilization in engines or systems. Aerodynamic drag refers to the resistive force air exerts on moving objects, impacting fuel consumption and overall vehicle performance. Understanding the balance between thermal efficiency and aerodynamic drag is crucial for optimizing energy use and enhancing transportation technologies.

Defining Thermal Efficiency in Engineering

Thermal efficiency in engineering measures how effectively a system converts heat energy into useful work, often represented as a percentage ratio of output work to input heat. It directly impacts the performance of engines and turbines by minimizing energy loss during combustion or heat transfer processes. Aerodynamic drag influences thermal efficiency by affecting the energy required to overcome resistance, thereby altering overall fuel consumption and system effectiveness.

Understanding Aerodynamic Drag

Aerodynamic drag significantly impacts thermal efficiency by increasing the energy required to overcome air resistance during motion, especially at higher speeds. Understanding aerodynamic drag involves analyzing factors such as drag coefficient, frontal area, and air density, which directly influence the power needed for propulsion. Reducing aerodynamic drag through streamlined design and surface treatments improves overall thermal efficiency by minimizing energy losses.

Key Differences: Thermal Efficiency vs Aerodynamic Drag

Thermal efficiency measures the effectiveness of an engine or system in converting fuel energy into useful work, typically expressed as a percentage of input energy converted to output power. Aerodynamic drag quantifies the resistance force exerted by air on a moving object, affecting the vehicle's speed and fuel consumption. The key difference lies in thermal efficiency focusing on energy conversion within the system, whereas aerodynamic drag relates to external forces impacting the system's performance and fuel economy.

Factors Affecting Thermal Efficiency

Thermal efficiency in vehicles is primarily influenced by engine design, combustion temperature, and fuel quality, which determine how effectively fuel energy converts into useful work. Aerodynamic drag impacts thermal efficiency indirectly by increasing engine load and fuel consumption as the vehicle encounters resistance at higher speeds. Optimizing factors such as cylinder compression ratio, air-fuel mixture, and minimizing drag coefficient contributes to improved thermal efficiency and overall energy savings.

Influences on Aerodynamic Drag

Aerodynamic drag is primarily influenced by factors such as the shape, surface roughness, and frontal area of a vehicle, which determine how air flows around it and increases resistance. Thermal efficiency impacts engine heat management systems, which can indirectly affect aerodynamic design by necessitating additional cooling vents or modifications. Optimizing vehicle geometry to reduce drag coefficients alongside efficient thermal management enhances overall fuel economy and performance.

Thermal Losses and Drag Forces: Impact on Performance

Thermal efficiency directly influences engine output by reducing thermal losses, which are energy dissipations as heat in combustion engines, enhancing fuel economy and power. Aerodynamic drag, caused by air resistance against a vehicle's surface, increases energy consumption and diminishes performance by requiring more power to maintain speed. Minimizing thermal losses and aerodynamic drag collectively optimizes overall system efficiency, improving speed, fuel savings, and environmental impact.

Strategies to Improve Thermal Efficiency

Improving thermal efficiency in vehicles involves optimizing engine design, enhancing combustion processes, and utilizing advanced materials for better heat retention and dissipation. Strategies such as turbocharging, direct fuel injection, and variable valve timing increase energy conversion rates while minimizing waste heat. Reducing aerodynamic drag complements these efforts by lowering engine load and fuel consumption, creating a synergistic effect for overall performance gains.

Methods to Minimize Aerodynamic Drag

Reducing aerodynamic drag enhances thermal efficiency by decreasing energy consumption required to overcome air resistance. Methods to minimize aerodynamic drag include streamlining vehicle shapes, using smooth underbodies, and integrating active grille shutters to control airflow. Implementing surface treatments such as vortex generators and low-friction coatings further reduces drag coefficients, optimizing overall vehicle performance.

Balancing Thermal Efficiency and Aerodynamic Drag in Design

Balancing thermal efficiency and aerodynamic drag in design requires optimizing the shape and materials to minimize heat loss while reducing air resistance. Advanced thermal insulation techniques combined with streamlined body contours can significantly enhance overall performance by maintaining engine or system efficiency without compromising speed or fuel economy. Computational fluid dynamics (CFD) simulations integrated with thermal analysis tools enable precise adjustments to achieve optimal synergy between thermal management and aerodynamic properties.

Thermal efficiency Infographic

libterm.com

libterm.com