Single shear refers to the type of stress that occurs when a material or structural element is subjected to forces acting in opposite directions but on a single plane, causing it to potentially fail along that plane. Understanding single shear is crucial in engineering and construction to ensure the safety and integrity of beams, bolts, and other components under load. Explore the rest of the article to learn more about the principles of single shear and its practical applications in your projects.

Table of Comparison

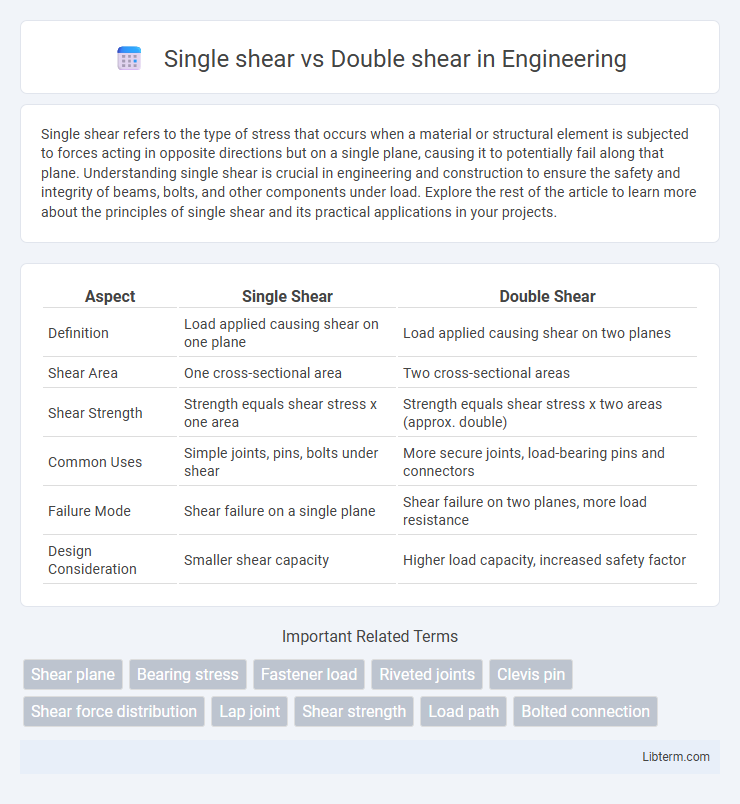

| Aspect | Single Shear | Double Shear |

|---|---|---|

| Definition | Load applied causing shear on one plane | Load applied causing shear on two planes |

| Shear Area | One cross-sectional area | Two cross-sectional areas |

| Shear Strength | Strength equals shear stress x one area | Strength equals shear stress x two areas (approx. double) |

| Common Uses | Simple joints, pins, bolts under shear | More secure joints, load-bearing pins and connectors |

| Failure Mode | Shear failure on a single plane | Shear failure on two planes, more load resistance |

| Design Consideration | Smaller shear capacity | Higher load capacity, increased safety factor |

Introduction to Shear Forces

Shear forces occur when a material is subjected to opposing forces that cause layers to slide past each other, creating stress along the shear plane. In single shear, the force acts on one shear plane, while double shear involves two parallel shear planes, effectively doubling the load-bearing capacity. Understanding the difference between single and double shear is crucial in structural design to ensure adequate resistance against shear failure.

Understanding Single Shear

Single shear occurs when a force is applied to a fastener or structural element, causing it to be cut along one plane, typically where two components overlap. This shear type subjects the fastener to stress concentrated on a single cross-sectional area, influencing the calculation of shear strength and failure modes. Understanding single shear is essential for designing connections in mechanical joints, bolts, rivets, and structural members to ensure adequate load-bearing capacity and prevent premature failure.

Understanding Double Shear

Double shear involves two shear planes, effectively distributing the applied load across both, which increases the joint's strength compared to single shear that has only one shear plane. This configuration reduces the stress on each plane, enhancing stability and load-bearing capacity in mechanical connections such as riveted or bolted joints. Engineers prefer double shear designs in critical applications where maximum shear resistance and safety margins are required.

Key Differences: Single vs Double Shear

Single shear involves a single plane of failure where the material is subjected to one shear force, while double shear occurs over two planes, effectively doubling the shear area and strength. In single shear, the load is transferred through a single cross-sectional area, whereas double shear distributes the load across two areas, reducing stress on each. This difference makes double shear joints generally stronger and more resistant to mechanical failure compared to single shear connections.

Applications of Single Shear

Single shear connections are widely used in structural applications where forces act primarily in one direction, such as in beam-to-column joints and simple riveted or bolted connections. These connections are suitable for scenarios requiring straightforward load transfer with less complexity and cost compared to double shear setups. Common applications include gate hinges, mechanical linkages, and certain types of pins and bolts where load is applied on one side of the fastener.

Applications of Double Shear

Double shear connections are widely used in structural engineering applications where enhanced load capacity and stability are critical, such as in truss joints, beam-to-column connections, and heavy machinery assemblies. These connections distribute the applied force across two shear planes, effectively doubling the shear area and improving resistance to shear failure. Industries like construction, automotive, and aerospace rely on double shear designs to ensure structural integrity under high-stress conditions.

Strength and Load Distribution Analysis

Single shear joints experience force across one shear plane, concentrating stress and typically resulting in lower load capacity compared to double shear joints. Double shear configurations distribute the applied load over two shear planes, effectively doubling the shear area and enhancing overall joint strength and durability. This improved load distribution minimizes stress concentration and increases the resistance to failure under tensile and shear forces.

Common Materials and Connectors Used

Single shear connections typically involve one shear plane where a bolt, rivet, or pin passes through two members, commonly used in steel and aluminum structures with fasteners like high-strength bolts or rivets. Double shear connections engage two shear planes, distributing the load across both sides of the connector, frequently applied in steel frameworks and timber joints using bolts, pins, or specialized connectors such as dowels. Common materials in these connections include carbon steel, stainless steel, and hardwoods, with connectors chosen based on shear capacity, corrosion resistance, and application requirements.

Advantages and Limitations Comparison

Single shear joints are simpler to design and analyze, making them cost-effective and easier to fabricate for applications with lower load demands. Double shear connections distribute forces more evenly across two shear planes, providing greater strength and reducing stress concentration, which is advantageous in heavy-load structures. However, double shear joints require more complex fabrication and alignment, increasing manufacturing costs and assembly time compared to single shear connections.

Conclusion and Best Practices

Single shear connections experience shear force on one plane, making them simpler but less robust compared to double shear connections, which distribute force across two planes, enhancing load-carrying capacity and reducing stress concentration. For optimal structural performance and safety, prioritize double shear designs in high-load applications, ensuring even load distribution and minimizing material fatigue. Regular inspection and maintenance of both connection types remain essential to uphold integrity and prevent failure over time.

Single shear Infographic

libterm.com

libterm.com