Cylindrical roller bearings are designed to support heavy radial loads with high precision and low friction, making them ideal for industrial machinery and automotive applications. Their unique roller design allows for reduced heat generation and extended service life in demanding environments. Discover how to maximize your equipment's performance by learning more about the key features and benefits of cylindrical roller bearings in the full article.

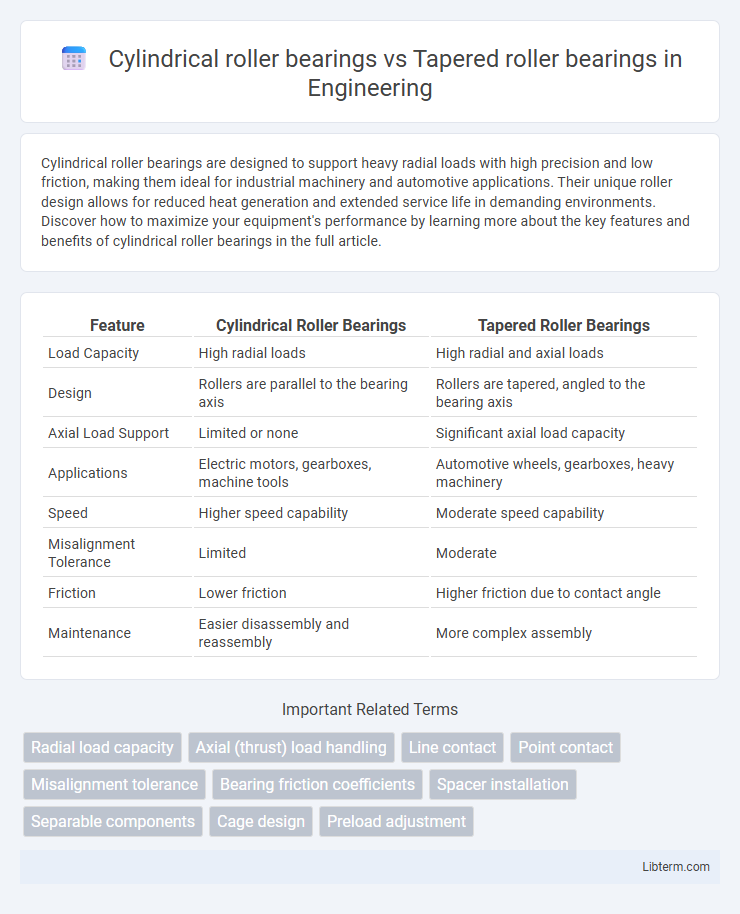

Table of Comparison

| Feature | Cylindrical Roller Bearings | Tapered Roller Bearings |

|---|---|---|

| Load Capacity | High radial loads | High radial and axial loads |

| Design | Rollers are parallel to the bearing axis | Rollers are tapered, angled to the bearing axis |

| Axial Load Support | Limited or none | Significant axial load capacity |

| Applications | Electric motors, gearboxes, machine tools | Automotive wheels, gearboxes, heavy machinery |

| Speed | Higher speed capability | Moderate speed capability |

| Misalignment Tolerance | Limited | Moderate |

| Friction | Lower friction | Higher friction due to contact angle |

| Maintenance | Easier disassembly and reassembly | More complex assembly |

Introduction to Roller Bearings

Cylindrical roller bearings feature rollers oriented parallel to the bearing axis, providing high radial load capacity and reduced friction for high-speed applications. Tapered roller bearings have conically shaped rollers that handle both radial and axial loads, making them ideal for combined load conditions. Both types are essential in mechanical systems for efficient load distribution and durability depending on the nature of the applied forces.

Overview of Cylindrical Roller Bearings

Cylindrical roller bearings feature rollers with a high length-to-diameter ratio, enabling them to support heavy radial loads while allowing for high-speed operation and low friction. Their design includes one or more rows of rollers that are guided by a cage, providing excellent rigidity and reduced heat generation compared to tapered roller bearings. Commonly used in electric motors, gearboxes, and machine tools, cylindrical roller bearings offer superior radial load capacity but limited axial load support relative to tapered roller bearings.

Overview of Tapered Roller Bearings

Tapered roller bearings are designed to handle both radial and axial loads through their conical geometry, which distributes stress more efficiently along the roller and raceway. Their tapered inner and outer ring profiles allow for higher load capacities and better alignment under heavy-duty conditions compared to cylindrical roller bearings. Commonly used in automotive, industrial machinery, and gearboxes, tapered roller bearings offer enhanced durability and precise load guidance in applications involving combined loads.

Design Differences Between Cylindrical and Tapered Roller Bearings

Cylindrical roller bearings feature rollers with a straight cylindrical shape that allows for high radial load capacity and minimal friction, enabling high-speed performance. Tapered roller bearings have conically shaped rollers designed to support combined radial and axial loads by distributing forces along the roller's contact angle. The internal geometry of cylindrical bearings permits purely radial load absorption, whereas tapered bearings leverage their angled design for enhanced axial load handling and alignment tolerance.

Load Capacity Comparison: Radial vs. Axial Loads

Cylindrical roller bearings offer superior radial load capacity due to their line contact design, making them ideal for applications with heavy radial forces. Tapered roller bearings handle both radial and significant axial loads effectively, thanks to the angled raceway design that supports combined load conditions. When axial load capacity is critical, tapered roller bearings outperform cylindrical ones, which primarily manage radial loads.

Speed Capabilities: Cylindrical vs. Tapered Bearings

Cylindrical roller bearings excel in high-speed applications due to their lower friction and ability to handle greater radial loads, making them suitable for electric motors and gearboxes. Tapered roller bearings, designed to support combined radial and axial loads, typically operate at lower speeds because their contact angles generate higher friction and heat. Selecting between these bearings depends on the balance between speed requirements and load-handling characteristics in industrial machinery.

Applications and Industry Uses

Cylindrical roller bearings excel in high-speed applications such as electric motors, gearboxes, and machine tools due to their ability to handle heavy radial loads and high speeds with low friction. Tapered roller bearings are preferred in automotive, construction, and mining industries where combined radial and axial loads are prevalent, offering superior support in wheel hubs, transmissions, and heavy machinery. Both bearing types are critical in industrial sectors, with cylindrical bearings dominating precision equipment and tapered bearings specialized for heavy-duty load management.

Bearing Installation and Maintenance Considerations

Cylindrical roller bearings require precise axial alignment during installation to prevent uneven load distribution and premature wear, while tapered roller bearings demand careful adjustment of preload and endplay to ensure optimal performance and longevity. Maintenance for cylindrical roller bearings centers on regular lubrication and contamination prevention to avoid surface fatigue, whereas tapered roller bearings need periodic inspection of raceway and roller surfaces for signs of edge loading and spalling. Proper installation tools and techniques, such as hydraulic presses for cylindrical bearings and calibrated torque settings for tapered bearings, are critical to maintaining bearing integrity and service life.

Advantages and Disadvantages: Cylindrical vs. Tapered Bearings

Cylindrical roller bearings offer high radial load capacity and reduced friction, making them ideal for high-speed applications but provide limited axial load support. Tapered roller bearings handle combined radial and axial loads effectively, thanks to their angled design, yet they generate higher friction and require more precise alignment. Choosing between them depends on specific load conditions, speed requirements, and desired durability in mechanical systems.

Choosing the Right Roller Bearing for Your Needs

Cylindrical roller bearings provide high radial load capacity and are ideal for applications requiring low friction and high-speed performance, such as electric motors and gearboxes. Tapered roller bearings handle combined radial and axial loads, making them suitable for automotive wheel hubs and heavy machinery where thrust forces are present. Selecting the appropriate roller bearing depends on the specific load conditions, speed requirements, and alignment tolerances of the application.

Cylindrical roller bearings Infographic

libterm.com

libterm.com