Servo motors provide precise control of angular position, velocity, and acceleration, making them essential in robotics, CNC machinery, and automation systems. Their ability to deliver high torque in a compact design allows for efficient and accurate movement in various industrial and hobbyist applications. Explore the rest of the article to understand how servo motors can enhance Your projects with optimal performance.

Table of Comparison

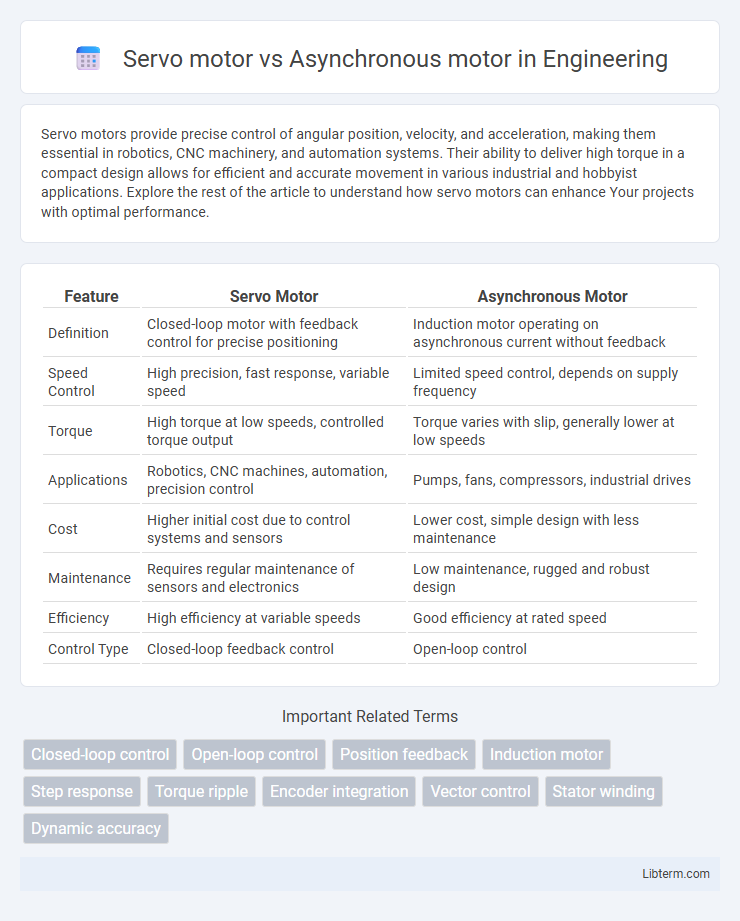

| Feature | Servo Motor | Asynchronous Motor |

|---|---|---|

| Definition | Closed-loop motor with feedback control for precise positioning | Induction motor operating on asynchronous current without feedback |

| Speed Control | High precision, fast response, variable speed | Limited speed control, depends on supply frequency |

| Torque | High torque at low speeds, controlled torque output | Torque varies with slip, generally lower at low speeds |

| Applications | Robotics, CNC machines, automation, precision control | Pumps, fans, compressors, industrial drives |

| Cost | Higher initial cost due to control systems and sensors | Lower cost, simple design with less maintenance |

| Maintenance | Requires regular maintenance of sensors and electronics | Low maintenance, rugged and robust design |

| Efficiency | High efficiency at variable speeds | Good efficiency at rated speed |

| Control Type | Closed-loop feedback control | Open-loop control |

Introduction to Servo Motors and Asynchronous Motors

Servo motors offer precise control of angular or linear position, velocity, and acceleration, making them ideal for applications requiring high accuracy, such as robotics and CNC machinery. Asynchronous motors, commonly known as induction motors, operate on the principle of electromagnetic induction and are favored for their robustness, simplicity, and efficiency in industrial drives and pumps. The key difference lies in the control mechanism: servo motors use feedback systems for exact positioning, whereas asynchronous motors run at speeds determined by the supply frequency without direct position feedback.

Core Differences: Servo vs Asynchronous Motors

Servo motors provide precise control of angular position, velocity, and acceleration through feedback systems, making them ideal for applications requiring high accuracy and dynamic response. Asynchronous motors, also known as induction motors, operate without direct feedback by inducing current via electromagnetic induction, offering robust and cost-effective performance for constant-speed industrial tasks. The core difference lies in servo motors' closed-loop control enabling fine-tuned motion, whereas asynchronous motors rely on slip and rotor currents for torque generation without precise positional feedback.

Working Principles Explained

Servo motors operate based on a closed-loop system where feedback from position sensors allows precise control of angular position, speed, and torque, making them ideal for applications requiring high accuracy. Asynchronous motors, also known as induction motors, function on the principle of electromagnetic induction where the rotor rotates at a speed slightly less than the synchronous speed, causing slip to induce current and generate torque without feedback mechanisms. The key difference lies in the control method: servo motors use feedback for dynamic precision control, while asynchronous motors rely on the slip between rotor and stator magnetic fields for operation.

Key Components and Construction

Servo motors feature a rotor with permanent magnets and a stator wound with multiple coils to enable precise control of position and speed, integrated with feedback devices such as encoders or resolvers for real-time performance monitoring. Asynchronous motors, also known as induction motors, consist of a squirrel cage rotor and a three-phase wound stator that generates a rotating magnetic field inducing current in the rotor without the need for brushes or feedback systems. The construction of servo motors emphasizes compact size and high-torque density with sophisticated electronics, whereas asynchronous motors prioritize simplicity, durability, and cost-effectiveness with rugged mechanical components.

Performance and Efficiency Comparison

Servo motors exhibit superior performance with precise control over speed, position, and torque, making them ideal for applications requiring high accuracy and dynamic response. Asynchronous motors generally offer higher efficiency in steady-state operations due to their simple design and reduced maintenance requirements. While servo motors sacrifice some efficiency for performance, asynchronous motors prioritize energy efficiency and durability in continuous, moderate-precision tasks.

Control Mechanisms and Precision

Servo motors utilize closed-loop control systems with feedback devices such as encoders or resolvers to achieve high precision and accurate position control, making them ideal for applications requiring fine motion control. Asynchronous motors, often controlled by variable frequency drives (VFDs), offer less precise speed regulation and lack inherent position feedback, resulting in lower accuracy suitable for less demanding applications. The superior control mechanisms in servo motors enable rapid response and precise torque delivery, contrasting with the simpler, more cost-effective control of asynchronous motors.

Applications and Industry Use Cases

Servo motors are widely utilized in precision control applications such as robotics, CNC machinery, and automated manufacturing lines where accurate position, velocity, and torque control are critical. Asynchronous motors, also known as induction motors, dominate industrial sectors like HVAC systems, conveyor belts, pumps, and fans due to their ruggedness, simplicity, and cost-effectiveness. The choice between servo and asynchronous motors depends on the demand for precise motion control versus general-purpose power drive in industries like automotive, aerospace, and heavy manufacturing.

Advantages and Limitations of Each Motor

Servo motors provide precise control of position, speed, and torque, making them ideal for applications requiring high accuracy, such as robotics and CNC machines. Their limitations include higher cost and complexity compared to asynchronous motors, along with the need for a feedback system. Asynchronous motors, also known as induction motors, offer robustness, low maintenance, and cost-effectiveness, but they lack the precision and speed control capabilities of servo motors, limiting their use in applications requiring exact positioning.

Cost Considerations and Maintenance

Servo motors generally have higher upfront costs due to their precise control systems and advanced components, but they offer reduced long-term maintenance expenses thanks to fewer mechanical parts and lower wear rates. In contrast, asynchronous motors feature lower initial investment and simpler construction, leading to widespread industrial use, yet they often incur higher maintenance costs caused by regular bearing replacements and rotor inspections. Optimal motor selection balances these cost considerations with performance requirements and lifecycle expectations.

Choosing the Right Motor for Your Needs

Servo motors provide precise control of position, speed, and torque, making them ideal for applications requiring high accuracy such as robotics and CNC machines. Asynchronous motors, also known as induction motors, offer robustness and simplicity at lower cost, suitable for continuous operation in industrial pumps, fans, and conveyors. Choosing the right motor depends on factors like required precision, speed control, load type, and budget constraints, with servo motors excelling in dynamic performance and asynchronous motors favored for durability and efficiency.

Servo motor Infographic

libterm.com

libterm.com