Direct control enables you to manage systems or devices instantly without intermediaries, improving efficiency and responsiveness. This method is widely used in automation, robotics, and real-time applications where precision is critical. Discover how mastering direct control can optimize your operations in the rest of this article.

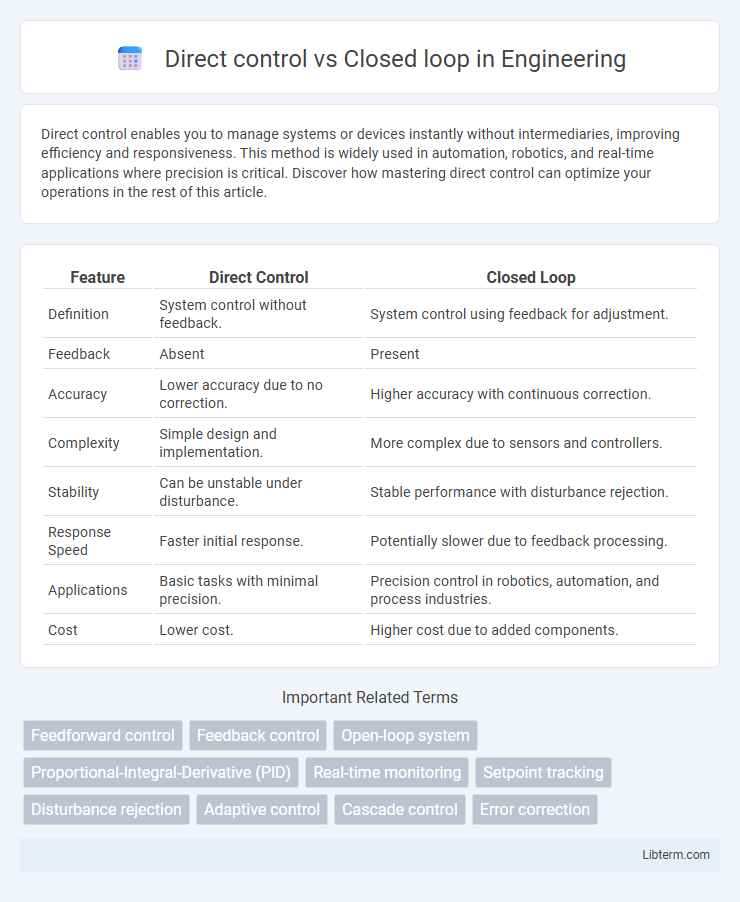

Table of Comparison

| Feature | Direct Control | Closed Loop |

|---|---|---|

| Definition | System control without feedback. | System control using feedback for adjustment. |

| Feedback | Absent | Present |

| Accuracy | Lower accuracy due to no correction. | Higher accuracy with continuous correction. |

| Complexity | Simple design and implementation. | More complex due to sensors and controllers. |

| Stability | Can be unstable under disturbance. | Stable performance with disturbance rejection. |

| Response Speed | Faster initial response. | Potentially slower due to feedback processing. |

| Applications | Basic tasks with minimal precision. | Precision control in robotics, automation, and process industries. |

| Cost | Lower cost. | Higher cost due to added components. |

Introduction to Direct Control and Closed Loop Systems

Direct control systems operate by applying a control action based solely on the current input without feedback, making them simpler but less adaptable to disturbances. Closed loop systems utilize feedback from output measurements to continuously adjust the control input, improving accuracy and stability in dynamic environments. The fundamental difference lies in the presence of feedback, where closed loop systems correct deviations automatically, unlike direct control systems that depend entirely on preset commands.

Key Differences Between Direct Control and Closed Loop

Direct control operates on a fixed input-output relationship without feedback, making it simpler but less adaptable to disturbances. Closed loop control continuously monitors output through sensors and adjusts inputs to maintain desired performance, offering higher accuracy and stability. The key difference lies in feedback integration, where closed loop systems dynamically correct errors, unlike direct control which functions open-loop.

How Direct Control Systems Work

Direct control systems operate by continuously monitoring the output and comparing it directly to a predetermined set point, adjusting the input without intermediary feedback mechanisms. These systems rely on real-time sensing elements such as thermostats or pressure sensors that trigger immediate corrective actions to maintain desired conditions. Unlike closed loop systems, direct control systems function with simple on-off or proportional control based solely on instantaneous deviations from the target value.

How Closed Loop Systems Work

Closed loop systems continuously monitor output through sensors to compare actual performance with desired setpoints, enabling automatic adjustments via feedback mechanisms. This real-time data feedback allows the system to correct errors and maintain stability, improving precision and efficiency compared to direct control systems. By dynamically adjusting inputs based on output variations, closed loop control minimizes deviations and adapts to changing conditions in processes like temperature regulation and motor speed control.

Advantages of Direct Control

Direct control offers rapid response times by minimizing feedback delays, making it ideal for applications requiring immediate adjustments. It simplifies system design by eliminating complex sensors and feedback loops, reducing maintenance and operational costs. This approach enhances system reliability due to fewer components prone to failure, ensuring consistent performance in dynamic environments.

Advantages of Closed Loop Systems

Closed loop systems offer precise feedback mechanisms that continuously monitor and adjust outputs for optimal performance, reducing errors and enhancing accuracy in control processes. These systems improve stability and reliability by compensating for disturbances and variations in the environment, leading to consistent and predictable operation. Enhanced efficiency in energy consumption and resource use is another advantage, as closed loop systems dynamically adapt to real-time conditions, minimizing waste and maximizing productivity.

Limitations of Direct Control

Direct control systems offer simplicity and low latency but lack adaptability to changing conditions, resulting in limited accuracy and efficiency. Without feedback mechanisms, these systems cannot compensate for disturbances or system nonlinearities, which restricts their use in complex or dynamic environments. Closed loop systems overcome these limitations by continuously monitoring output and adjusting control inputs, enhancing precision and robustness.

Limitations of Closed Loop Systems

Closed loop systems face limitations such as increased complexity and higher costs due to the need for sensors and feedback mechanisms. These systems can suffer from delays in response time and potential instability if the feedback is not properly tuned. Environmental disturbances and noise can also degrade the accuracy and reliability of closed loop control, limiting overall performance.

Practical Applications: Direct Control vs Closed Loop

Direct control systems are widely used in simple applications such as home heating thermostats and basic industrial machines where immediate response is critical without feedback adjustments. Closed loop systems dominate complex processes like robotics, automotive cruise control, and HVAC systems, as they continuously monitor output conditions and adjust inputs to maintain desired performance. Practical applications favor closed loop control in scenarios requiring precision and adaptability, whereas direct control suits straightforward tasks with minimal variability.

Choosing the Right Control System: Factors to Consider

Choosing the right control system hinges on factors such as precision, stability, and response time, where closed-loop systems offer superior accuracy through feedback mechanisms, while direct control systems provide simplicity and faster implementation. Assessing environmental variability, system complexity, and required tolerance levels guides the selection between closed-loop's dynamic adjustment capabilities and the straightforward nature of direct control. Evaluating costs, maintenance demands, and scalability also influences the decision to ensure optimal performance and reliability in specific application contexts.

Direct control Infographic

libterm.com

libterm.com