The Split Hopkinson Pressure Bar (SHPB) is a crucial apparatus for testing the dynamic behavior of materials at high strain rates, enabling precise measurement of stress, strain, and strain rate. It uses two bars--incident and transmission bars--with the specimen sandwiched between them, capturing wave propagation to analyze material response under impact loading. Explore this article to understand how the SHPB works and its applications in materials science and engineering testing.

Table of Comparison

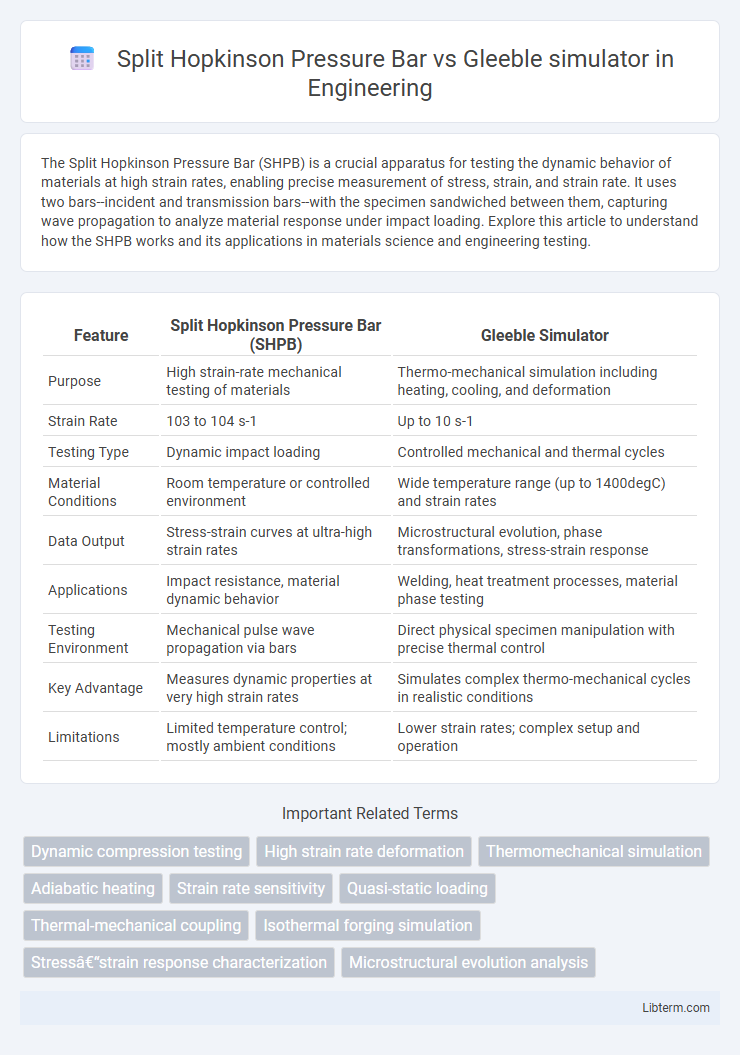

| Feature | Split Hopkinson Pressure Bar (SHPB) | Gleeble Simulator |

|---|---|---|

| Purpose | High strain-rate mechanical testing of materials | Thermo-mechanical simulation including heating, cooling, and deformation |

| Strain Rate | 103 to 104 s-1 | Up to 10 s-1 |

| Testing Type | Dynamic impact loading | Controlled mechanical and thermal cycles |

| Material Conditions | Room temperature or controlled environment | Wide temperature range (up to 1400degC) and strain rates |

| Data Output | Stress-strain curves at ultra-high strain rates | Microstructural evolution, phase transformations, stress-strain response |

| Applications | Impact resistance, material dynamic behavior | Welding, heat treatment processes, material phase testing |

| Testing Environment | Mechanical pulse wave propagation via bars | Direct physical specimen manipulation with precise thermal control |

| Key Advantage | Measures dynamic properties at very high strain rates | Simulates complex thermo-mechanical cycles in realistic conditions |

| Limitations | Limited temperature control; mostly ambient conditions | Lower strain rates; complex setup and operation |

Introduction to High-Strain-Rate Testing Methods

High-strain-rate testing methods are essential for understanding material behavior under rapid loading conditions. The Split Hopkinson Pressure Bar (SHPB) system is widely recognized for its ability to measure stress-strain response at strain rates typically between 10^2 to 10^4 s^-1, making it ideal for dynamic impact and high-rate deformation analysis. In contrast, the Gleeble simulator offers precise control over temperature and strain rate, enabling simulation of complex thermomechanical processes with strain rates ranging from quasi-static to moderate high rates, crucial for metal forming and welding studies.

Overview of the Split Hopkinson Pressure Bar (SHPB)

The Split Hopkinson Pressure Bar (SHPB) is a high-strain-rate testing apparatus designed to evaluate material behavior under dynamic loading conditions, typically ranging from 10^2 to 10^4 s^-1 strain rates. The SHPB system comprises incident and transmitted bars, strain gauges, and a striker bar to generate stress waves that induce rapid deformation in the specimen. This method is essential for characterizing the mechanical properties of metals, composites, and ceramics under impact or crash scenarios, providing critical data for dynamic material modeling.

Fundamentals of the Gleeble Simulator

The Gleeble simulator operates on the principle of thermomechanical simulation, allowing precise control of temperature, strain rate, and deformation to replicate real-world thermal and mechanical material processing conditions. It uses resistance heating and mechanical loading to study phase transformations, microstructural evolution, and mechanical behavior under controlled laboratory environments. Unlike the Split Hopkinson Pressure Bar, which primarily focuses on high strain rate impact loading, the Gleeble system integrates complex thermal cycles with mechanical testing for comprehensive material characterization.

Key Principles: SHPB vs. Gleeble Operation

The Split Hopkinson Pressure Bar (SHPB) operates by generating high strain rates through stress waves transmitted along elastic bars to test dynamic material behavior under rapid loading conditions. In contrast, the Gleeble simulator employs direct resistance heating combined with mechanical systems to precisely control temperature and deformation rates for simulating thermomechanical processing of metals. While SHPB emphasizes transient stress wave propagation for strain rate study, Gleeble focuses on thermomechanical coupling to replicate industrial forming and heat treatment processes.

Specimen Preparation and Experimental Setup

The Split Hopkinson Pressure Bar (SHPB) requires cylindrical or dog-bone-shaped specimens precisely machined to fit between the incident and transmitted bars, ensuring accurate wave propagation during high strain-rate testing. In contrast, the Gleeble simulator accommodates a broader range of specimen geometries, including flat tensile or compression samples, and integrates heating elements for thermal-mechanical testing under controlled temperature gradients. Specimen preparation for SHPB emphasizes surface finish and alignment to minimize stress concentrations, while Gleeble's setup involves mounting specimens in grips with thermocouples and often a vacuum chamber to simulate service conditions comprehensively.

Data Acquisition and Measurement Capabilities

Split Hopkinson Pressure Bar (SHPB) offers high-frequency dynamic data acquisition with precise stress, strain, and strain rate measurements during impact tests, enabling detailed analysis of material behavior under extreme loading. In contrast, Gleeble simulators provide versatile thermal-mechanical data acquisition capabilities with integrated sensors for temperature, force, and deformation, allowing real-time control and measurement during thermomechanical processing. Both systems utilize advanced data capture technologies, but SHPB excels in dynamic impact loading scenarios, while Gleeble excels in simulating complex thermal cycles with accurate multi-parameter measurements.

Advantages and Limitations: SHPB vs. Gleeble

Split Hopkinson Pressure Bar (SHPB) offers high strain rate testing essential for studying dynamic material behavior, with advantages including precise stress-strain measurement and suitability for metals and composites under impact conditions. However, SHPB is limited by specimen size constraints and complexity in capturing thermal effects. In contrast, the Gleeble simulator excels in thermomechanical processing with precise temperature and deformation control, enabling simulation of welding and hot working processes; its limitations include lower strain rate capabilities and reduced effectiveness for extremely high-speed dynamic testing.

Applications in Material Science and Engineering

Split Hopkinson Pressure Bar (SHPB) is primarily used for high strain rate testing of materials to evaluate dynamic mechanical properties such as stress-strain behavior, impact resistance, and failure mechanisms in metals, polymers, and composites. Gleeble simulators provide precise control of temperature, strain rate, and mechanical deformation, allowing researchers to replicate welding, hot working, and thermo-mechanical processing conditions for phase transformation and microstructure evolution studies. Both devices are essential in material science for optimizing mechanical performance and predicting material behavior under extreme service conditions.

Comparative Case Studies and Research Outcomes

Comparative case studies between Split Hopkinson Pressure Bar (SHPB) and Gleeble simulator reveal distinct advantages tailored to high strain rate testing and thermomechanical simulation, respectively. Research outcomes highlight SHPB's precision in dynamic material characterization under extreme strain rates, while Gleeble excels in replicating complex thermal and mechanical cycles for microstructural evolution analysis. Integrating data from both systems enhances comprehensive understanding of material behavior under combined mechanical and thermal stresses.

Future Trends and Innovations in High-Strain Testing

The Split Hopkinson Pressure Bar (SHPB) continues to evolve with advancements in high-speed data acquisition and digital signal processing, enabling more precise stress-strain measurements at microsecond timescales. Gleeble simulators are integrating real-time thermal-mechanical coupling and advanced in-situ microstructural characterization, enhancing the accuracy of simulations for complex alloy behavior under rapid deformation. Future innovations emphasize hybrid testing platforms combining SHPB's high-strain rate capabilities with Gleeble's thermal control, fostering comprehensive materials characterization for aerospace, automotive, and defense industries.

Split Hopkinson Pressure Bar Infographic

libterm.com

libterm.com