Spot welding is a precise and efficient technique used to join metal surfaces by applying pressure and heat generated from electrical resistance at the welding point. It is widely used in automotive manufacturing and metal fabrication due to its speed and strong bond formation between thin metal sheets. Discover how spot welding can enhance your manufacturing process and explore detailed insights in the rest of the article.

Table of Comparison

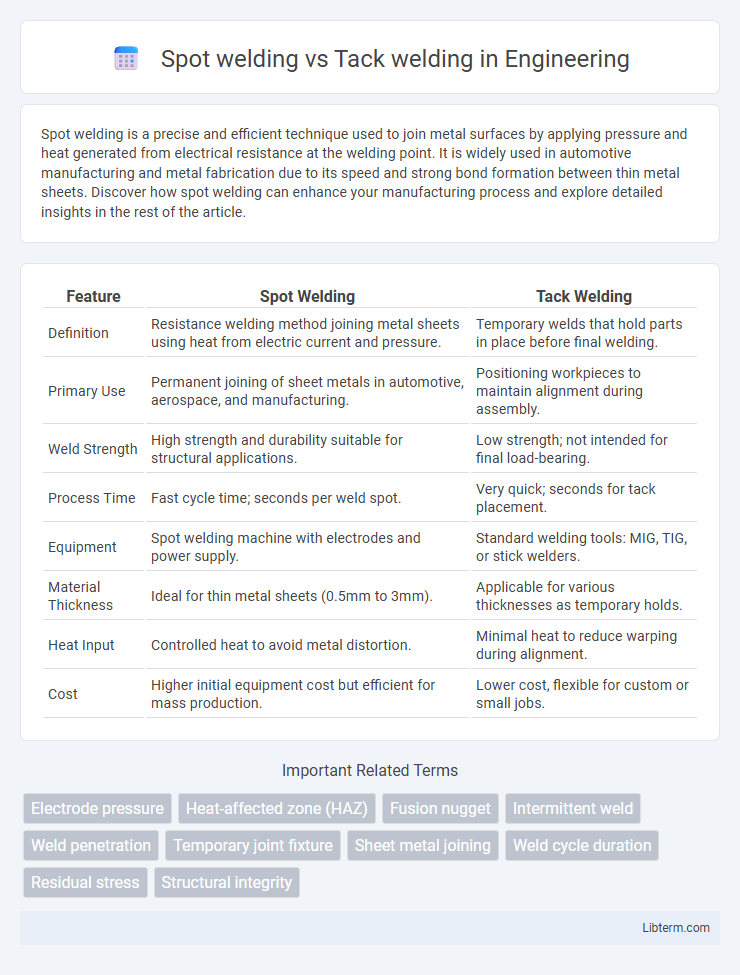

| Feature | Spot Welding | Tack Welding |

|---|---|---|

| Definition | Resistance welding method joining metal sheets using heat from electric current and pressure. | Temporary welds that hold parts in place before final welding. |

| Primary Use | Permanent joining of sheet metals in automotive, aerospace, and manufacturing. | Positioning workpieces to maintain alignment during assembly. |

| Weld Strength | High strength and durability suitable for structural applications. | Low strength; not intended for final load-bearing. |

| Process Time | Fast cycle time; seconds per weld spot. | Very quick; seconds for tack placement. |

| Equipment | Spot welding machine with electrodes and power supply. | Standard welding tools: MIG, TIG, or stick welders. |

| Material Thickness | Ideal for thin metal sheets (0.5mm to 3mm). | Applicable for various thicknesses as temporary holds. |

| Heat Input | Controlled heat to avoid metal distortion. | Minimal heat to reduce warping during alignment. |

| Cost | Higher initial equipment cost but efficient for mass production. | Lower cost, flexible for custom or small jobs. |

Introduction to Spot Welding and Tack Welding

Spot welding is a resistance welding process that joins overlapping metal sheets by applying heat generated from electrical resistance and pressure at specific points. Tack welding involves creating small, temporary welds to hold parts in place before final welding, ensuring alignment and stability during assembly. Both techniques are essential in metal fabrication, with spot welding offering strong, permanent joints and tack welding providing preliminary positioning support.

Definition and Process of Spot Welding

Spot welding is a resistance welding process that joins two or more metal sheets by applying pressure and passing an electric current through the metal at localized points, causing the material to melt and fuse together. The process involves placing the metal sheets between two copper electrodes, which conduct the electrical current and apply force to create the weld. Spot welding is commonly used in automotive manufacturing and sheet metal fabrication due to its speed, strength, and efficiency for joining thin metal parts.

Definition and Process of Tack Welding

Tack welding involves creating small, temporary welds to hold metal pieces in place before the final welding process, preventing movement and ensuring alignment. This process uses brief, controlled heat application to form small weld spots without full penetration, making it faster and less energy-intensive than spot welding. Unlike spot welding, which fuses metals through high electrical current at overlapping joints, tack welding is primarily a positioning technique used in fabrication and assembly.

Key Differences Between Spot Welding and Tack Welding

Spot welding joins metal sheets by applying pressure and heat from an electric current at specific points, creating strong, permanent welds ideal for high-strength applications. Tack welding involves creating small, temporary welds to hold components in place before final welding, ensuring proper alignment and reducing distortion. Key differences include the permanence of welds, with spot welding providing durable bonds and tack welding serving as a preliminary fixing method.

Common Applications in Industry

Spot welding is predominantly used in the automotive and manufacturing industries for joining sheet metals quickly and efficiently, particularly in assembling car bodies and metal furniture. Tack welding serves as a preliminary joining technique across aerospace and construction sectors, providing temporary holds to align components before final welding. Both methods are integral to mass production and fabrication processes, enhancing structural integrity and assembly precision.

Advantages of Spot Welding

Spot welding offers rapid and strong welds ideal for joining thin metal sheets, enhancing production efficiency in automotive and manufacturing industries. This method provides consistent weld quality with minimal distortion, reducing post-weld processing and improving structural integrity. Spot welding's automation compatibility further lowers labor costs and increases repeatability compared to tack welding.

Advantages of Tack Welding

Tack welding offers precise positioning advantages by temporarily joining metal pieces, ensuring accurate alignment before final welding. It reduces distortion and warping in complex assemblies due to minimal heat input compared to spot welding. The process also increases efficiency in multi-part fabrication by allowing quick, temporary holds that facilitate later adjustments.

Limitations and Challenges

Spot welding faces limitations such as restricted thickness compatibility, risk of electrode wear, and difficulty in maintaining consistent weld quality on uneven surfaces. Tack welding challenges include lower joint strength compared to full welds, potential for misalignment during assembly, and being unsuitable for high-stress applications due to incomplete fusion. Both welding methods require precise electrode control and surface preparation to minimize defects and ensure durability.

Choosing the Right Welding Method

Choosing the right welding method depends on the specific application and material type. Spot welding excels in joining thin metal sheets with high strength and efficiency, making it ideal for automotive and manufacturing industries. Tack welding, on the other hand, provides temporary, low-strength welds to hold components in place for alignment before final welding, offering flexibility in complex assemblies and repairs.

Conclusion and Recommendations

Spot welding offers strong, permanent joints ideal for high-volume manufacturing, while tack welding provides temporary holds suitable for alignment and positioning in fabrication processes. Choosing between spot welding and tack welding depends on the project requirements, with spot welding recommended for load-bearing structures and tack welding favored during assembly stages prior to final welding. For optimal results, integrate tack welding to secure components before applying spot welding to ensure precise and durable connections.

Spot welding Infographic

libterm.com

libterm.com