An addendum circle is a geometric concept formed by drawing a circle that is tangent to a specific segment of a triangle, often associated with the triangle's excircles or incircle. Understanding the properties of addendum circles can enhance your ability to solve complex problems in Euclidean geometry and improve insights into triangle centers and their relations. Dive deeper into this article to explore the definitions, properties, and applications of addendum circles in various geometric contexts.

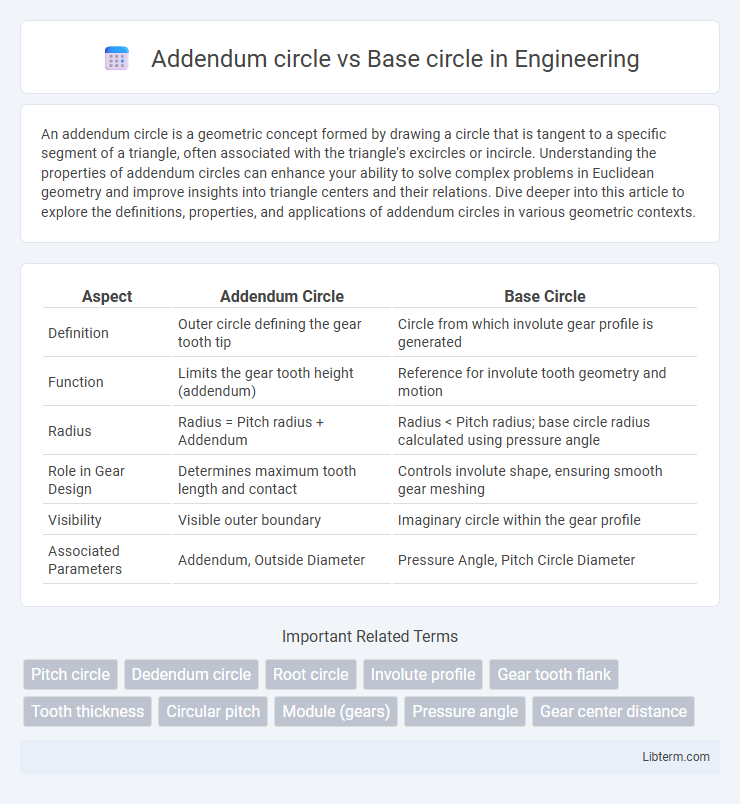

Table of Comparison

| Aspect | Addendum Circle | Base Circle |

|---|---|---|

| Definition | Outer circle defining the gear tooth tip | Circle from which involute gear profile is generated |

| Function | Limits the gear tooth height (addendum) | Reference for involute tooth geometry and motion |

| Radius | Radius = Pitch radius + Addendum | Radius < Pitch radius; base circle radius calculated using pressure angle |

| Role in Gear Design | Determines maximum tooth length and contact | Controls involute shape, ensuring smooth gear meshing |

| Visibility | Visible outer boundary | Imaginary circle within the gear profile |

| Associated Parameters | Addendum, Outside Diameter | Pressure Angle, Pitch Circle Diameter |

Introduction to Gear Geometry

The addendum circle represents the outermost boundary of a gear tooth, defining the tip where the gear engages with a mating gear. The base circle serves as the foundational reference from which the involute tooth profile is generated, critical for accurate gear meshing and smooth transmission of motion. Understanding the distinction between the addendum and base circles is essential for designing gear geometry that ensures efficient power transfer and minimizes wear.

Defining Addendum Circle

The addendum circle is the outermost circle of a gear, representing the maximum diameter where the teeth extend beyond the base circle. It defines the tip of the gear teeth, crucial for calculating the gear's working depth and clearance. The base circle, located inside the addendum circle, serves as the reference for generating the involute tooth profile essential in gear design.

Understanding Base Circle

The base circle is a fundamental geometric element in gear design, serving as the starting point for the involute tooth profile, which ensures smooth and efficient power transmission. Unlike the addendum circle that defines the outermost boundary of a gear tooth, the base circle determines the involute curve from which the tooth shape is generated, directly influencing gear meshing and contact ratio. Precise calculation of the base circle diameter, based on pitch diameter and pressure angle, is crucial for maintaining accurate gear geometry and minimizing operational noise and wear.

Key Differences: Addendum Circle vs Base Circle

The addendum circle represents the outermost boundary of gear teeth, defining the maximum diameter of the gear, while the base circle is the fundamental circle from which the involute tooth profile is generated. The addendum circle radius is larger than the base circle radius, with the base circle located inside the pitch circle and the addendum circle outside it. Key differences include that the addendum circle affects gear mesh clearance and tooth height, whereas the base circle determines the involute curve and gear tooth shape precision.

Importance of Addendum Circle in Gear Design

The addendum circle defines the outermost boundary of a gear tooth, crucial for determining the gear's effective working diameter and ensuring proper meshing with mating gears. This circle influences the gear's capacity to transmit torque without interference or undercutting, directly impacting the efficiency and lifespan of the gear system. Accurate calculation of the addendum circle is essential for optimizing gear performance and minimizing noise and wear in mechanical transmissions.

Role of Base Circle in Involute Gear Profiles

The base circle is fundamental in defining the involute curve of gear teeth, serving as the generating circle from which the involute profile is unwound, ensuring smooth and constant velocity ratio during gear meshing. Unlike the addendum circle, which determines the outer limit of the gear teeth, the base circle controls the geometry and kinematics of the tooth profile. Precise calculation and design of the base circle radius directly influence the gear's efficiency and operational reliability by maintaining correct contact and minimizing stress concentrations.

Calculating Addendum and Base Circles

The addendum circle defines the outermost boundary of a gear tooth and is calculated by adding the addendum length, typically one module (m), to the pitch circle radius (r = d/2), resulting in an addendum circle radius of r_addendum = r + m. The base circle radius is crucial for involute gear tooth profiles and is derived from the pitch circle radius multiplied by the cosine of the pressure angle (a), expressed as r_base = r * cos(a). Accurate calculation of both circles ensures precise gear tooth geometry necessary for proper meshing and power transmission in gear systems.

Impact on Gear Performance and Meshing

The addendum circle represents the outermost boundary of gear teeth, directly influencing the gear's ability to engage and transmit power efficiently by determining the contact ratio and load distribution. The base circle serves as the fundamental reference for involute tooth profiles, impacting the accuracy of meshing and smoothness of motion transfer by defining the gear's pitch and pressure angle. Proper alignment and proportion between the addendum circle and base circle optimize gear performance by minimizing backlash, reducing noise, and enhancing durability during operation.

Common Applications and Use Cases

Addendum circle and base circle are essential concepts in gear design influencing rolling contact and power transmission efficiency. The addendum circle defines the outermost boundary of gear teeth, crucial for ensuring proper mesh and clearance in applications like automotive transmissions and industrial machinery. The base circle underpins the involute tooth profile, directly affecting gear accuracy and smoothness in high-precision devices such as robotics and aerospace gear systems.

Summary: Choosing the Right Reference Circle

Selecting the appropriate reference circle between the addendum circle and base circle depends on gear design requirements and analysis precision. The addendum circle defines the outermost boundary of gear teeth, crucial for determining gear size and clearance, while the base circle is fundamental in generating the involute tooth profile, impacting gear meshing accuracy. Engineers often use the base circle for precise kinematic calculations, whereas the addendum circle is essential for ensuring proper tooth engagement and avoiding interference.

Addendum circle Infographic

libterm.com

libterm.com