Laminated material offers enhanced durability, resistance to moisture, and improved structural integrity, making it ideal for various applications from packaging to construction. This process involves bonding multiple layers together to combine the best properties of each material. Explore the rest of the article to discover how laminated materials can benefit your projects and industries.

Table of Comparison

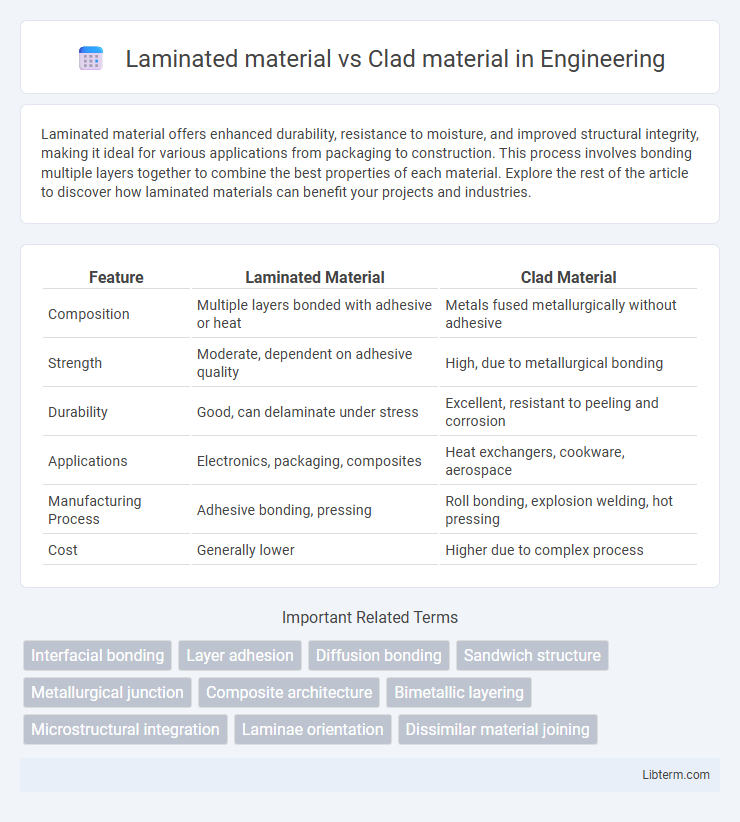

| Feature | Laminated Material | Clad Material |

|---|---|---|

| Composition | Multiple layers bonded with adhesive or heat | Metals fused metallurgically without adhesive |

| Strength | Moderate, dependent on adhesive quality | High, due to metallurgical bonding |

| Durability | Good, can delaminate under stress | Excellent, resistant to peeling and corrosion |

| Applications | Electronics, packaging, composites | Heat exchangers, cookware, aerospace |

| Manufacturing Process | Adhesive bonding, pressing | Roll bonding, explosion welding, hot pressing |

| Cost | Generally lower | Higher due to complex process |

Overview of Laminated and Clad Materials

Laminated materials consist of multiple layers bonded together, often combining properties like strength, flexibility, and resistance to moisture or chemicals. Clad materials feature a core substrate coated or bonded with a different metal or material to enhance surface properties such as corrosion resistance, conductivity, or aesthetic appeal. Both laminated and clad materials are extensively used in industries like aerospace, construction, and electronics for their tailored performance characteristics.

Core Differences Between Laminated and Clad Materials

Laminated materials consist of multiple layers of the same or different materials bonded together using adhesives or heat, optimizing structural strength and flexibility. Clad materials involve a metallic core bonded to a different metal or alloy layer, enhancing corrosion resistance and surface durability without altering the mechanical properties of the core. The primary difference lies in their manufacturing process and application, where laminated materials focus on combined material benefits, while clad materials integrate protective outer layers with a robust core.

Manufacturing Processes Compared

Laminated materials are produced by bonding multiple layers of the same or different materials through heat, pressure, or adhesives, enhancing mechanical strength and stability. Clad materials involve metallurgically bonding dissimilar metals during processes like extrusion or rolling, creating composites with combined properties such as corrosion resistance and conductivity. Manufacturing laminated structures is often more versatile and cost-effective, while cladding requires precise control of temperature and pressure to ensure metallurgical bonding without compromising material integrity.

Material Composition and Structure

Laminated materials consist of multiple layers of similar or different materials bonded together to enhance mechanical strength, flexibility, or thermal resistance, often incorporating adhesives or binders between layers. Clad materials are formed by metallurgically bonding two or more dissimilar metal layers, such as aluminum to copper or steel to stainless steel, resulting in a composite structure with distinct layers that retain individual metal properties. The key difference lies in laminated composites using non-metallic adhesives and layers, while cladding relies on metallurgical fusion to create a seamless metal-metal interface.

Mechanical Properties Evaluation

Laminated materials exhibit superior mechanical properties due to their multi-layered structure, which enhances strength, toughness, and resistance to cracking by effectively distributing stress across layers. In contrast, clad materials combine distinct metals to optimize corrosion resistance and surface hardness while maintaining a tougher core, but their mechanical behavior often depends on the adhesion quality between layers. Mechanical properties evaluation typically involves assessing tensile strength, impact resistance, and fatigue life, where laminated materials generally outperform clad materials in impact toughness and delamination resistance.

Applications Across Industries

Laminated materials, known for their enhanced strength and durability, are widely used in automotive panels, packaging, and electronics for improved protection and aesthetic appeal. Clad materials, combining different metals to leverage unique properties such as corrosion resistance and conductivity, find extensive application in aerospace, construction, and electrical industries. Both materials optimize performance by tailoring surface characteristics to specific environmental and operational demands.

Durability and Performance Analysis

Laminated materials exhibit superior durability due to their multi-layered structure, which enhances resistance to wear, moisture, and impact, making them ideal for high-stress environments. Clad materials, combining different metals through bonding, offer exceptional performance in corrosion resistance and thermal conductivity, suitable for applications requiring robust surface properties. Performance analysis reveals laminated materials excel in flexibility and shock absorption, whereas clad materials provide enhanced strength and conductivity, optimizing them for specific industrial uses.

Cost Considerations and Economic Impact

Laminated materials generally offer a lower upfront cost due to simpler manufacturing processes, making them economically attractive for high-volume production. Clad materials, while more expensive initially because of advanced bonding techniques and higher-quality base metals, provide superior durability and corrosion resistance, potentially reducing long-term maintenance expenses. Evaluating total lifecycle costs reveals that selecting clad materials can result in better economic value for applications requiring enhanced performance and longevity.

Environmental and Sustainability Factors

Laminated materials typically involve bonding layers of different substances using adhesives, which can complicate recycling due to mixed-material separation challenges, resulting in higher environmental impact compared to clad materials. Clad materials, created through metallurgical bonding processes without adhesives, offer improved recyclability and longer lifecycle due to their uniform composition and enhanced durability. Sustainable manufacturing favors clad materials for reducing waste and energy consumption during recycling, aligning with circular economy principles.

Choosing the Right Material for Your Project

Laminated materials offer enhanced durability and resistance to moisture, making them ideal for high-traffic or outdoor projects. Clad materials provide superior aesthetic appeal and corrosion resistance, perfect for architectural and decorative applications. Selecting the right material depends on project requirements such as environmental exposure, structural strength, and budget constraints.

Laminated material Infographic

libterm.com

libterm.com