Decentralized control distributes decision-making authority across multiple agents, enhancing system flexibility and fault tolerance. This approach optimizes resource allocation and improves scalability in complex, dynamic environments. Explore the rest of the article to understand how decentralized control can benefit your systems and operations.

Table of Comparison

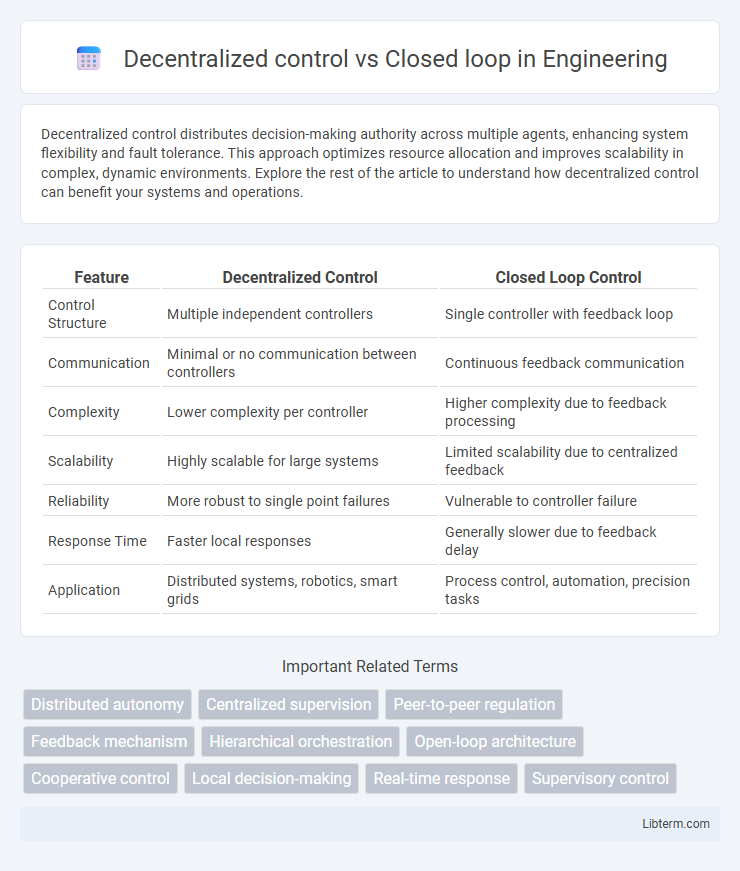

| Feature | Decentralized Control | Closed Loop Control |

|---|---|---|

| Control Structure | Multiple independent controllers | Single controller with feedback loop |

| Communication | Minimal or no communication between controllers | Continuous feedback communication |

| Complexity | Lower complexity per controller | Higher complexity due to feedback processing |

| Scalability | Highly scalable for large systems | Limited scalability due to centralized feedback |

| Reliability | More robust to single point failures | Vulnerable to controller failure |

| Response Time | Faster local responses | Generally slower due to feedback delay |

| Application | Distributed systems, robotics, smart grids | Process control, automation, precision tasks |

Introduction to Control Systems

Decentralized control involves multiple controllers managing individual subsystems independently, enhancing scalability and fault tolerance in complex systems. Closed-loop control continuously monitors output feedback to adjust input, achieving accurate and stable system performance. Understanding these control strategies is fundamental in designing efficient and reliable control systems across various engineering applications.

What is Decentralized Control?

Decentralized control refers to a control system where multiple controllers operate independently, each managing a specific subsystem or component without relying on a central controller. This approach enhances scalability and fault tolerance by distributing decision-making across local controllers, which act based on local measurements and information. Unlike closed loop systems that rely on feedback to correct errors globally, decentralized control emphasizes modularity and local autonomy in complex environments.

Understanding Closed Loop Control

Closed loop control systems continuously monitor output performance through feedback signals, enabling automatic adjustments to maintain desired system behavior despite disturbances. This method contrasts with decentralized control, where individual subsystems operate independently without real-time coordination, potentially leading to inefficiencies. Understanding closed loop control is critical for optimizing system stability and accuracy in applications such as industrial automation and robotics.

Key Differences Between Decentralized and Closed Loop Control

Decentralized control involves multiple independent controllers managing different parts of a system without global coordination, while closed loop control relies on feedback to continuously adjust a single controller's output for system stability. Decentralized control offers scalability and fault tolerance but may lack the precision of closed loop systems, which optimize performance through real-time error correction. Key differences include the level of inter-controller communication, feedback utilization, and system complexity management.

Advantages of Decentralized Control

Decentralized control offers significant advantages such as improved system reliability by isolating faults to individual subsystems, reducing the risk of total system failure. It enhances scalability and flexibility, allowing easy modifications and expansions without redesigning the entire control architecture. Furthermore, decentralized control reduces communication overhead and latency, enabling faster response times in complex, distributed processes like smart grids and industrial automation.

Benefits of Closed Loop Systems

Closed loop systems offer precise regulation by continuously monitoring output and adjusting inputs, resulting in improved accuracy and stability. These systems reduce errors and disturbances, enhancing performance in dynamic environments such as robotics and process automation. Their feedback mechanism enables adaptive control, leading to increased efficiency and reliability compared to decentralized control systems.

Common Applications and Use Cases

Decentralized control systems are widely used in large-scale industrial processes such as chemical plants, oil refineries, and power generation, where multiple controllers manage different subsystems independently to enhance reliability and scalability. Closed loop control is essential in precision applications like robotics, aerospace, and automotive systems, ensuring stability and accuracy by continuously monitoring output and adjusting inputs based on feedback signals. Both control strategies are leveraged in areas such as HVAC systems, manufacturing automation, and process control, depending on the requirements for responsiveness, complexity, and fault tolerance.

Challenges and Limitations

Decentralized control faces challenges such as limited global system knowledge, leading to suboptimal coordination and potential instability in complex networks. Closed-loop systems, while offering real-time feedback for improved accuracy, encounter limitations including latency, sensor inaccuracies, and computational overhead. Both approaches struggle with scalability issues in large-scale applications and balancing robustness against dynamic environmental changes.

Future Trends in Control System Architectures

Future trends in control system architectures emphasize the integration of decentralized control and advanced closed-loop mechanisms to enhance system scalability and resilience. Advances in edge computing and IoT enable decentralized control systems to operate with real-time data feedback, improving adaptability and fault tolerance. Machine learning algorithms embedded within closed-loop frameworks are expected to optimize decision-making processes, driving autonomous and efficient control solutions across industrial applications.

Choosing the Right Control Strategy

Choosing the right control strategy depends on system complexity, performance requirements, and scalability. Decentralized control offers advantages in modularity and fault tolerance by distributing control tasks across independent units, suitable for large-scale or geographically dispersed systems. Closed-loop control provides precise feedback-based adjustments to maintain stability and accuracy, ideal for processes demanding tight regulation and rapid response.

Decentralized control Infographic

libterm.com

libterm.com