Heat exchanger effectiveness measures how efficiently heat is transferred between fluids, influenced heavily by the flow arrangement such as counterflow, parallel flow, or crossflow. Counterflow arrangements typically offer higher effectiveness due to the greater temperature gradient over the heat exchanger length, improving overall thermal performance. Discover more about how different flow arrangements impact your heat exchanger's efficiency in the rest of the article.

Table of Comparison

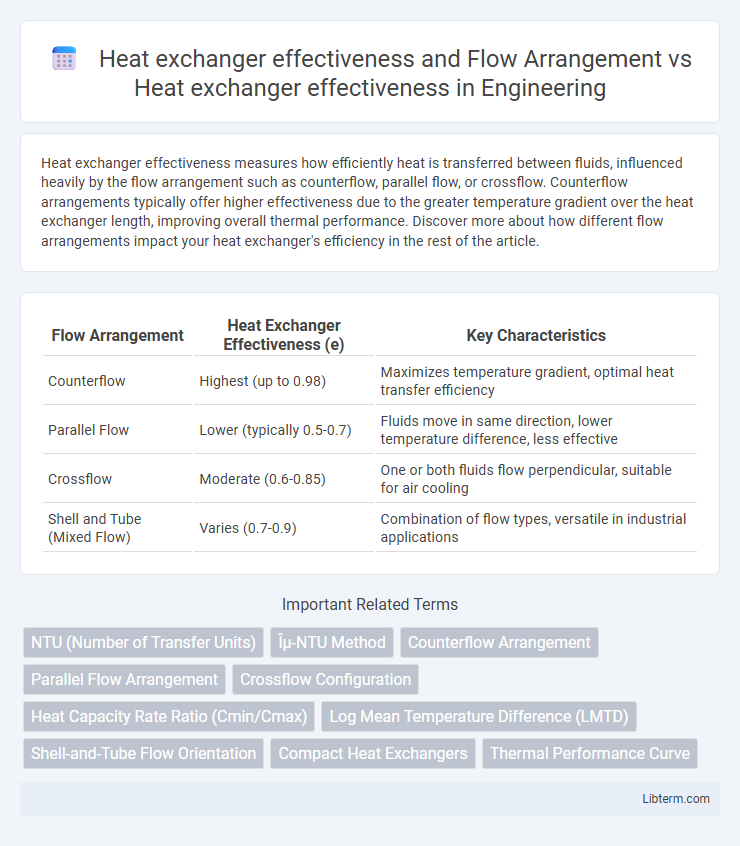

| Flow Arrangement | Heat Exchanger Effectiveness (e) | Key Characteristics |

|---|---|---|

| Counterflow | Highest (up to 0.98) | Maximizes temperature gradient, optimal heat transfer efficiency |

| Parallel Flow | Lower (typically 0.5-0.7) | Fluids move in same direction, lower temperature difference, less effective |

| Crossflow | Moderate (0.6-0.85) | One or both fluids flow perpendicular, suitable for air cooling |

| Shell and Tube (Mixed Flow) | Varies (0.7-0.9) | Combination of flow types, versatile in industrial applications |

Introduction to Heat Exchanger Effectiveness

Heat exchanger effectiveness measures the efficiency of heat transfer between hot and cold fluid streams, indicating the ratio of actual heat transfer to the maximum possible heat transfer. Flow arrangement, such as counterflow, parallel flow, or crossflow, significantly influences heat exchanger effectiveness by affecting temperature gradients and heat transfer rates within the device. Counterflow arrangements generally yield the highest effectiveness due to the optimal temperature difference maintained across the length of the heat exchanger.

Key Factors Influencing Heat Exchanger Performance

Heat exchanger effectiveness is heavily influenced by the flow arrangement, where counterflow configurations typically achieve higher thermal performance compared to parallel flow due to greater temperature gradients. Key factors impacting heat exchanger effectiveness include the specific heat capacity rates of the fluids, overall heat transfer coefficient, and the surface area available for heat exchange. Fluid velocity and flow regime also play critical roles by affecting the convective heat transfer coefficient, thereby altering the overall heat exchanger effectiveness.

Defining Heat Exchanger Effectiveness

Heat exchanger effectiveness measures the efficiency with which a heat exchanger transfers heat between hot and cold fluids, defined as the ratio of actual heat transfer to the maximum possible heat transfer under ideal conditions. Flow arrangement, such as counterflow, parallel flow, or crossflow, significantly impacts effectiveness by influencing temperature gradients and heat transfer rates between fluids. Counterflow arrangements typically achieve higher effectiveness compared to parallel flow due to the maintained temperature difference along the length of the heat exchanger.

Types of Flow Arrangements in Heat Exchangers

Heat exchanger effectiveness measures the efficiency of heat transfer between two fluids, directly influenced by the flow arrangement within the device; common types include parallel flow, counterflow, and crossflow configurations. Counterflow heat exchangers generally achieve the highest effectiveness due to the maximum temperature difference maintained along the heat transfer surface. Crossflow and parallel flow arrangements typically exhibit lower effectiveness, with parallel flow being the least efficient, as both fluids travel in the same direction, reducing the temperature gradient.

Parallel Flow vs. Counterflow Configurations

Heat exchanger effectiveness depends significantly on the flow arrangement, with counterflow configurations typically achieving higher effectiveness compared to parallel flow designs due to the greater temperature gradient maintained along the length of the exchanger. In counterflow heat exchangers, the hot and cold fluids move in opposite directions, allowing the cold fluid to exit at a temperature closer to the hot fluid inlet temperature, thus maximizing heat transfer efficiency. Parallel flow arrangements, where both fluids travel in the same direction, generally result in lower effectiveness as the temperature difference decreases rapidly along the exchanger, limiting heat transfer capacity.

Impact of Flow Arrangement on Effectiveness

Flow arrangement significantly impacts heat exchanger effectiveness by influencing the temperature gradient between fluids; counterflow configurations typically achieve higher effectiveness due to maintaining a larger average temperature difference along the heat exchanger length. Parallel flow arrangements result in lower effectiveness since hot and cold fluids enter from the same end, causing rapid temperature equilibrium and reduced heat transfer efficiency. Crossflow and multipass designs offer intermediate effectiveness, balancing compactness and temperature profiles for specific industrial applications.

Crossflow and Its Effect on Heat Transfer Efficiency

Crossflow heat exchangers exhibit moderate effectiveness due to one fluid flowing perpendicular to the other, creating varying temperature gradients across the surface area. The arrangement limits temperature driving force compared to counterflow designs but enhances heat transfer by reducing thermal boundary layers and frictional losses. Optimizing crossflow configurations can improve heat exchanger performance in applications requiring compact size and moderate heat transfer efficiency.

Mathematical Models for Effectiveness Calculation

Heat exchanger effectiveness is mathematically modeled based on the ratio of actual heat transfer to maximum possible heat transfer, influenced by flow arrangements such as counterflow, parallel flow, and crossflow. Effectiveness (e) is calculated using the Number of Transfer Units (NTU) method, where e depends on NTU and the capacity rate ratio (C_r = C_min/C_max), with distinct formulas for each flow configuration. Counterflow arrangements typically exhibit higher effectiveness values due to optimal temperature gradients, characterized by e = (1 - exp[-NTU(1-C_r)]) / (1 - C_r exp[-NTU(1-C_r)]) in mathematical modeling.

Optimization Strategies for Enhancing Heat Exchanger Effectiveness

Heat exchanger effectiveness directly depends on the flow arrangement, with counterflow configurations typically offering higher thermal efficiency compared to parallel flow due to greater temperature gradients and improved heat transfer rates. Optimization strategies involve selecting appropriate flow patterns, enhancing surface area through extended surfaces or turbulators, and minimizing fouling to maintain consistent thermal performance. Implementing advanced design techniques such as multi-pass arrangements and optimizing fluid velocities further elevates heat exchanger effectiveness in various industrial applications.

Practical Applications and Case Studies

Heat exchanger effectiveness is crucial in determining the efficiency of thermal energy transfer in industrial applications such as chemical processing and HVAC systems. Counterflow arrangements typically exhibit higher effectiveness than parallel flow due to greater temperature gradients, leading to improved heat recovery in case studies involving power plant condensers and refrigeration cycles. Practical applications demonstrate that optimizing flow arrangement enhances performance metrics, reduces operational costs, and increases system reliability.

Heat exchanger effectiveness and Flow Arrangement Infographic

libterm.com

libterm.com