Uniform corrosion occurs evenly across metal surfaces, gradually degrading material integrity without localized damage. This predictable corrosion type allows for easier assessment and maintenance planning to extend the lifespan of metal structures. Discover effective prevention and control methods in the rest of the article to protect your assets.

Table of Comparison

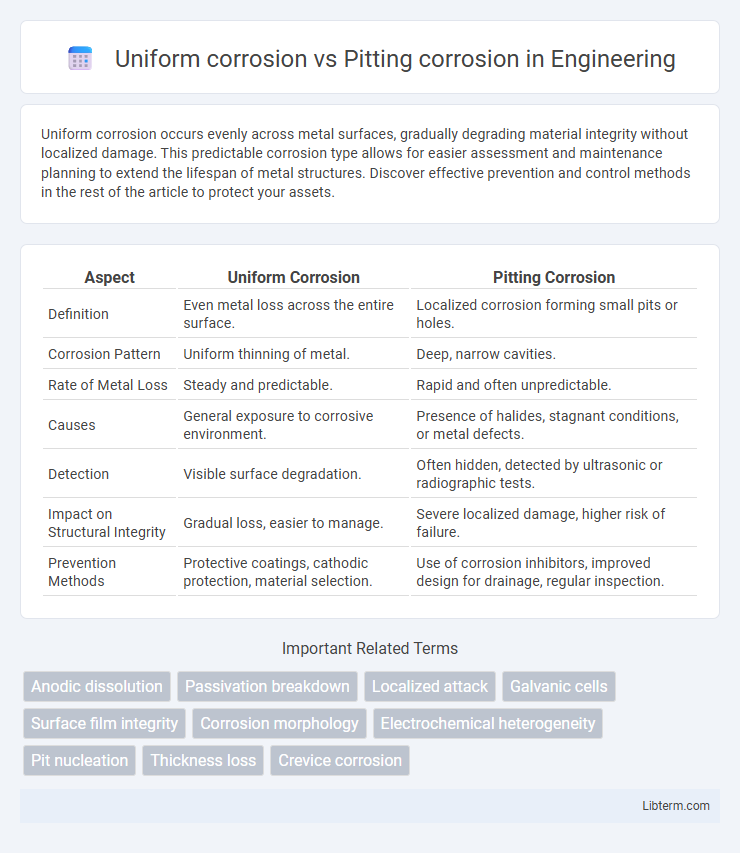

| Aspect | Uniform Corrosion | Pitting Corrosion |

|---|---|---|

| Definition | Even metal loss across the entire surface. | Localized corrosion forming small pits or holes. |

| Corrosion Pattern | Uniform thinning of metal. | Deep, narrow cavities. |

| Rate of Metal Loss | Steady and predictable. | Rapid and often unpredictable. |

| Causes | General exposure to corrosive environment. | Presence of halides, stagnant conditions, or metal defects. |

| Detection | Visible surface degradation. | Often hidden, detected by ultrasonic or radiographic tests. |

| Impact on Structural Integrity | Gradual loss, easier to manage. | Severe localized damage, higher risk of failure. |

| Prevention Methods | Protective coatings, cathodic protection, material selection. | Use of corrosion inhibitors, improved design for drainage, regular inspection. |

Introduction to Uniform and Pitting Corrosion

Uniform corrosion occurs evenly across a metal surface, leading to a consistent thinning that can be predicted and measured over time. Pitting corrosion is a localized attack that creates small, deep cavities or pits, often causing rapid failure with minimal overall material loss. Both types pose significant challenges in industrial environments, with uniform corrosion affecting general durability and pitting corrosion threatening structural integrity due to its unpredictable nature.

Understanding Uniform Corrosion

Uniform corrosion involves a consistent and even metal loss across the entire surface, leading to predictable material degradation. This type of corrosion typically occurs in environments where the corrosive agent interacts uniformly, allowing for easier detection and maintenance planning. Understanding uniform corrosion is crucial for industries such as oil and gas, where controlled thinning of pipelines can be monitored to prevent sudden failures.

Overview of Pitting Corrosion

Pitting corrosion is a localized form of corrosion characterized by the formation of small, deep cavities or pits on the metal surface, often leading to structural failure despite minimal overall material loss. It occurs when the passive oxide film on metals like stainless steel and aluminum is disrupted, allowing aggressive ions such as chloride to penetrate and cause accelerated metal dissolution at specific spots. Unlike uniform corrosion that uniformly reduces metal thickness, pitting corrosion poses a higher risk due to its hidden nature and rapid progression at the pit sites.

Key Differences Between Uniform and Pitting Corrosion

Uniform corrosion results in even material loss across the surface, typically caused by exposure to a corrosive environment like acidic or saline solutions. Pitting corrosion is highly localized, creating small, deep cavities or pits that penetrate the material, often initiated by chloride ions in stainless steel or aluminum alloys. Key differences include the predictability and detection ease of uniform corrosion versus the hidden, aggressive nature of pitting, which can cause sudden structural failure despite minimal overall material loss.

Causes and Mechanisms of Uniform Corrosion

Uniform corrosion occurs due to a consistent chemical or electrochemical reaction between a metal surface and its surrounding environment, often caused by exposure to oxygen, moisture, and corrosive agents like acids or salts. The mechanism involves a homogeneous oxidation process where the entire surface corrodes at roughly the same rate, resulting in a gradual thinning of the metal. Factors influencing uniform corrosion include the metal's composition, environmental pH, temperature, and the presence of conductive electrolytes facilitating electron transfer.

Factors Contributing to Pitting Corrosion

Pitting corrosion occurs due to localized breakdown of the protective oxide film on metals, often triggered by chloride ions, low oxygen concentration, and surface heterogeneities such as inclusions or scratches. It is exacerbated by acidic environments, crevices, and stagnant conditions that prevent the diffusion of corrosion inhibitors. Unlike uniform corrosion, which affects the entire surface evenly, pitting corrosion results in small, deep pits that can cause rapid structural failure.

Effects on Material Integrity

Uniform corrosion causes a consistent material loss across the entire surface, leading to predictable thinning and gradual weakening of structural components. Pitting corrosion creates localized cavities or pits, significantly compromising material integrity by initiating crack formation and accelerating failure under stress. The concentrated nature of pitting corrosion often results in sudden and unexpected breaches, posing greater risks to safety and durability compared to uniform corrosion.

Detection and Identification Methods

Uniform corrosion is typically detected through visual inspection, weight loss measurement, and thickness gauging using ultrasonic testing, enabling easy identification due to its even material degradation. Pitting corrosion requires more sensitive methods such as scanning electron microscopy (SEM), localized electrochemical impedance spectroscopy (LEIS), or dye penetrant testing to reveal small, often hidden pits and localized damage. Electrochemical noise analysis (ENA) and radiographic testing further assist in early identification of pitting by detecting localized changes in corrosion rate before visible pits appear.

Prevention and Control Strategies

Uniform corrosion prevention relies on protective coatings, cathodic protection, and corrosion inhibitors that create a consistent barrier over the entire metal surface. Pitting corrosion control requires localized protection methods such as applying highly resistant alloys, maintaining proper environmental conditions to avoid chloride accumulation, and regular inspections to detect early pit formation. Both strategies emphasize material selection and environmental management to minimize metal degradation and extend service life.

Industry Applications and Case Studies

Uniform corrosion occurs evenly across surfaces and is commonly observed in pipelines, storage tanks, and marine structures, where consistent material loss demands regular maintenance to prevent failure. Pitting corrosion, characterized by localized attack forming small cavities, poses significant risks in chloride-rich environments such as chemical processing plants and offshore oil rigs, often leading to catastrophic leaks if undetected. Case studies in the petrochemical industry highlight the economic impact of pitting corrosion on stainless steel heat exchangers, while uniform corrosion management strategies have proven effective in water treatment facilities by utilizing corrosion inhibitors and protective coatings.

Uniform corrosion Infographic

libterm.com

libterm.com