FMEA (Failure Mode and Effects Analysis) is a systematic method used to identify potential failure modes in a process, product, or system and assess their impact on performance. This proactive approach helps prioritize risks by severity, occurrence, and detection, enabling teams to implement effective corrective actions and improve overall reliability. Explore the rest of the article to understand how FMEA can enhance your quality management and risk mitigation strategies.

Table of Comparison

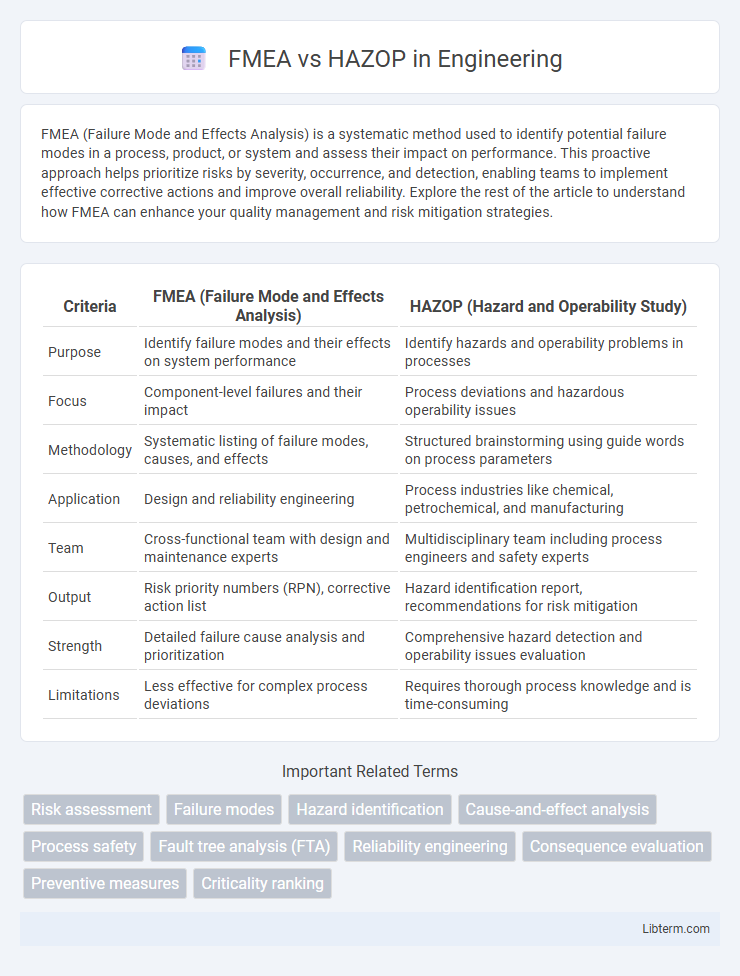

| Criteria | FMEA (Failure Mode and Effects Analysis) | HAZOP (Hazard and Operability Study) |

|---|---|---|

| Purpose | Identify failure modes and their effects on system performance | Identify hazards and operability problems in processes |

| Focus | Component-level failures and their impact | Process deviations and hazardous operability issues |

| Methodology | Systematic listing of failure modes, causes, and effects | Structured brainstorming using guide words on process parameters |

| Application | Design and reliability engineering | Process industries like chemical, petrochemical, and manufacturing |

| Team | Cross-functional team with design and maintenance experts | Multidisciplinary team including process engineers and safety experts |

| Output | Risk priority numbers (RPN), corrective action list | Hazard identification report, recommendations for risk mitigation |

| Strength | Detailed failure cause analysis and prioritization | Comprehensive hazard detection and operability issues evaluation |

| Limitations | Less effective for complex process deviations | Requires thorough process knowledge and is time-consuming |

Introduction to FMEA and HAZOP

FMEA (Failure Modes and Effects Analysis) identifies potential failure modes within a system and assesses their impact to prioritize mitigation efforts, primarily focusing on reliability and failure prevention in design and processes. HAZOP (Hazard and Operability Study) systematically examines process deviations to identify hazards and operability problems, emphasizing safety and regulatory compliance in industrial operations. Both methodologies enhance risk management by enabling early detection and control of system vulnerabilities.

Definition and Core Principles of FMEA

FMEA (Failure Mode and Effects Analysis) systematically identifies potential failure modes within a system, assesses their impact, and prioritizes risks to improve reliability and safety. Its core principles include failure mode identification, severity and occurrence evaluation, and implementation of corrective actions to mitigate risks. HAZOP (Hazard and Operability Study), in contrast, focuses on identifying process deviations and operational hazards through structured team analysis to enhance process safety.

Definition and Core Principles of HAZOP

HAZOP (Hazard and Operability Study) is a structured and systematic technique aimed at identifying potential hazards and operability problems through detailed examination of process deviations using guide words. The core principles of HAZOP involve a multidisciplinary team analyzing process parameters such as flow, temperature, and pressure to detect deviations from design intentions that could lead to safety risks or operational inefficiencies. Unlike FMEA, which focuses on failure modes and their effects on system components, HAZOP emphasizes process design and operational hazards by studying deviations in process variables to ensure safe and efficient plant operation.

Key Differences Between FMEA and HAZOP

FMEA (Failure Mode and Effects Analysis) systematically identifies potential failure modes in components or processes and prioritizes them based on severity, occurrence, and detection, emphasizing reliability improvement. HAZOP (Hazard and Operability Study) focuses on identifying hazards and operability problems in process systems through a structured team-based examination of deviations using guide words. Key differences include FMEA's component-level failure focus versus HAZOP's process deviation analysis, and FMEA's quantitative risk ranking contrasting with HAZOP's qualitative hazard identification.

Comparative Strengths and Weaknesses

FMEA excels in identifying potential failure modes in individual components or processes with a structured, quantitative approach, making it ideal for detailed risk assessment in design and manufacturing. HAZOP offers a systematic examination of entire processes by using guide words to uncover deviations, proving stronger in complex, continuous chemical or industrial process systems. While FMEA provides precise failure rankings, it may overlook systemic interactions that HAZOP effectively identifies, though HAZOP can be more resource-intensive and less granular in pinpointing specific failure causes.

Typical Applications in Industry

FMEA (Failure Modes and Effects Analysis) is widely applied in the automotive, aerospace, and manufacturing sectors to systematically identify potential failure modes and prioritize risk mitigation. HAZOP (Hazard and Operability Study) is predominantly used in chemical, petrochemical, and pharmaceutical industries to analyze process deviations and ensure safety and operability in complex systems. Both methodologies enhance risk management, with FMEA focusing on component-level failures and HAZOP targeting process flow and operational hazards.

Implementation Process: FMEA vs HAZOP

FMEA implementation involves a structured approach of identifying potential failure modes, assessing their effects, and prioritizing risks based on severity, occurrence, and detection ratings, often facilitated by cross-functional teams. HAZOP implementation requires systematic examination of process deviations through guide words and parameters, typically conducted in detailed workshops with multidisciplinary experts to identify hazards and operability issues. FMEA emphasizes quantitative risk ranking for preventive actions, whereas HAZOP focuses on qualitative identification of hazards related to process deviations and their operability impacts.

Tools and Techniques for Analysis

FMEA (Failure Modes and Effects Analysis) utilizes a systematic approach to identify potential failure modes, their causes, and effects on system performance, emphasizing severity, occurrence, and detection ratings to prioritize risks. HAZOP (Hazard and Operability Study) employs a structured brainstorming technique guided by predefined keywords, analyzing deviations from design intent to identify hazards and operability problems in process systems. Both tools integrate multidisciplinary teams and rely on detailed process documentation, but FMEA is quantitative with risk priority numbers, while HAZOP is qualitative, focusing on qualitative deviation analysis.

Integrating FMEA and HAZOP for Optimal Risk Management

Integrating FMEA (Failure Modes and Effects Analysis) and HAZOP (Hazard and Operability Study) provides a comprehensive approach to risk management by combining FMEA's detailed failure mode analysis with HAZOP's process deviation identification. This integration enhances hazard identification, improves risk prioritization, and supports the development of more effective mitigation strategies in complex industrial environments. Leveraging both methodologies enables organizations to optimize safety performance, reduce operational risks, and ensure regulatory compliance more efficiently.

Choosing the Right Method for Your Project

FMEA (Failure Modes and Effects Analysis) excels in identifying potential failures in product design and manufacturing processes, making it ideal for projects requiring detailed risk assessment at the component or process level. HAZOP (Hazard and Operability Study) is best suited for complex chemical, industrial, or process plants where deviations from design intent can lead to safety or operational hazards. Selecting the right method depends on project scope and industry: FMEA targets failure risk reduction in discrete systems, while HAZOP emphasizes hazard identification and operability in continuous or batch processes.

FMEA Infographic

libterm.com

libterm.com