Elastic modulus quantifies a material's ability to resist deformation under stress, reflecting its stiffness and elasticity. Understanding this property is essential for selecting materials in construction, engineering, and product design to ensure durability and performance. Explore the full article to discover how elastic modulus impacts your projects and material choices.

Table of Comparison

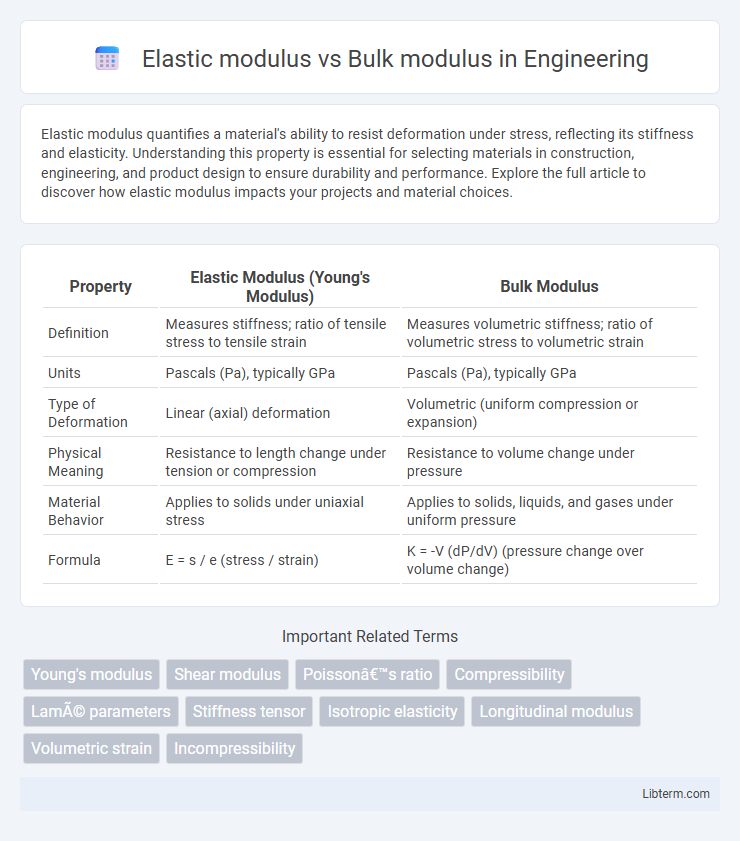

| Property | Elastic Modulus (Young's Modulus) | Bulk Modulus |

|---|---|---|

| Definition | Measures stiffness; ratio of tensile stress to tensile strain | Measures volumetric stiffness; ratio of volumetric stress to volumetric strain |

| Units | Pascals (Pa), typically GPa | Pascals (Pa), typically GPa |

| Type of Deformation | Linear (axial) deformation | Volumetric (uniform compression or expansion) |

| Physical Meaning | Resistance to length change under tension or compression | Resistance to volume change under pressure |

| Material Behavior | Applies to solids under uniaxial stress | Applies to solids, liquids, and gases under uniform pressure |

| Formula | E = s / e (stress / strain) | K = -V (dP/dV) (pressure change over volume change) |

Introduction to Elastic Modulus and Bulk Modulus

Elastic modulus measures a material's resistance to elastic deformation under tensile or compressive stress, reflecting stiffness along a specific direction. Bulk modulus quantifies a material's resistance to uniform compression, indicating its incompressibility under hydrostatic pressure. Both moduli are fundamental mechanical properties that describe how materials respond to different stress conditions, critical for engineering and materials science applications.

Fundamental Concepts of Modulus in Materials Science

Elastic modulus quantifies a material's ability to resist deformation under tensile or compressive stress, reflecting stiffness in one-dimensional loading scenarios. Bulk modulus measures a material's resistance to uniform volumetric compression, indicating how incompressible a substance is under pressure applied equally in all directions. Both moduli are fundamental mechanical properties used to characterize material behavior, with elastic modulus focusing on shape change and bulk modulus on volume change.

Definition of Elastic Modulus

Elastic modulus, also known as Young's modulus, measures a material's ability to resist deformation under tensile or compressive stress, quantifying stiffness in the linear elastic region. It is defined as the ratio of tensile stress to tensile strain along a specific axis, expressed in pascals (Pa). Unlike the bulk modulus, which characterizes volumetric compression resistance, elastic modulus focuses primarily on uniaxial stress and strain relationships.

Definition of Bulk Modulus

Bulk modulus measures a material's resistance to uniform compression, defined as the ratio of applied pressure to the resulting fractional volume decrease. It quantifies how incompressible a substance is under isotropic pressure. Unlike elastic modulus, which relates to tensile or shear stress, bulk modulus specifically addresses volumetric elasticity.

Key Differences Between Elastic Modulus and Bulk Modulus

Elastic modulus measures a material's resistance to uniaxial deformation under tensile or compressive stress, reflecting stiffness along a specific direction, while bulk modulus quantifies resistance to uniform volumetric compression under pressure, indicating incompressibility. Elastic modulus is expressed in units of pressure such as gigapascals (GPa) and directly relates stress to strain within the elastic limit, whereas bulk modulus defines the ratio of applied pressure to relative volumetric change. Key differences also lie in their applications across mechanical and materials engineering: elastic modulus is critical for structural deformation analysis, while bulk modulus is essential for fluid dynamics and solid mechanics involving volume changes.

Physical Significance and Applications

Elastic modulus quantifies a material's resistance to uniaxial deformation, reflecting stiffness under tensile or compressive stress, critical for designing structural components like beams and shafts. Bulk modulus measures a material's resistance to uniform volumetric compression, essential for understanding fluid behaviors and applications in hydraulics and geophysics. Both moduli enable accurate predictions of material response under different loading conditions, improving performance in mechanical engineering, aerospace, and material science.

Mathematical Formulas and Relationships

Elastic modulus (E) quantifies a material's stiffness under uniaxial stress, defined mathematically as E = s/e, where s is stress and e is strain. Bulk modulus (K) measures a material's resistance to uniform volumetric compression, expressed as K = -V (dP/dV), with P representing pressure and V volume. The relationship between them for isotropic materials incorporates Poisson's ratio (n), given by E = 3K(1 - 2n), linking elastic modulus, bulk modulus, and lateral strain effects.

Measurement Methods for Both Moduli

Elastic modulus is commonly measured using tensile or compressive testing, where stress-strain curves provide the necessary data to calculate stiffness in uniaxial loading conditions. Bulk modulus measurement typically involves hydrostatic compression tests, where pressure changes in an enclosed volume of a material yield data on volumetric elasticity. Both methods rely on precise instrumentation such as strain gauges, pressure transducers, and extensometers to ensure accurate determination of mechanical properties.

Examples of Materials and Their Moduli Values

Steel exhibits a high elastic modulus of approximately 200 GPa, indicating its resistance to elastic deformation, while its bulk modulus is around 160 GPa, reflecting its resistance to uniform compression. Rubber has a low elastic modulus near 0.01 GPa, demonstrating high elasticity, contrasted with a bulk modulus approximately 0.1 GPa, showing its relative incompressibility. Materials like glass show an elastic modulus of about 70 GPa and a bulk modulus near 35 GPa, highlighting differences in tensile stiffness versus volumetric compression resistance.

Summary: Choosing the Right Modulus for Engineering Applications

Elastic modulus measures a material's stiffness under tensile or compressive stress, essential for structures subjected to shape changes. Bulk modulus quantifies resistance to uniform pressure and volumetric compression, critical in applications involving fluid or gas containment. Selecting the right modulus depends on whether the engineering design prioritizes shape retention (elastic modulus) or volume stability under pressure (bulk modulus).

Elastic modulus Infographic

libterm.com

libterm.com