Heat exchanger effectiveness measures how efficiently a heat exchanger transfers heat between fluids relative to the maximum possible transfer. The Number of Transfer Units (NTU) is a dimensionless parameter that helps predict this effectiveness by comparing the heat exchanger's size and thermal capacity to the fluid's heat capacity rates. Explore the rest of the article to understand how these concepts impact your heat exchanger design and performance optimization.

Table of Comparison

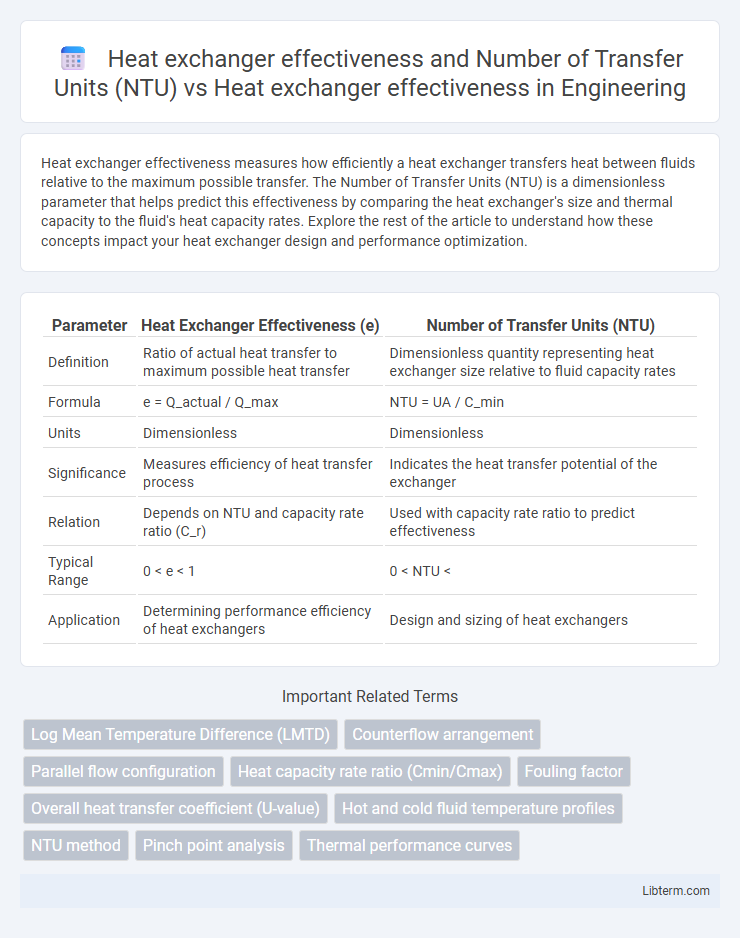

| Parameter | Heat Exchanger Effectiveness (e) | Number of Transfer Units (NTU) |

|---|---|---|

| Definition | Ratio of actual heat transfer to maximum possible heat transfer | Dimensionless quantity representing heat exchanger size relative to fluid capacity rates |

| Formula | e = Q_actual / Q_max | NTU = UA / C_min |

| Units | Dimensionless | Dimensionless |

| Significance | Measures efficiency of heat transfer process | Indicates the heat transfer potential of the exchanger |

| Relation | Depends on NTU and capacity rate ratio (C_r) | Used with capacity rate ratio to predict effectiveness |

| Typical Range | 0 < e < 1 | 0 < NTU < |

| Application | Determining performance efficiency of heat exchangers | Design and sizing of heat exchangers |

Introduction to Heat Exchanger Effectiveness

Heat exchanger effectiveness quantifies the actual heat transfer relative to the maximum possible heat transfer between two fluids, serving as a critical performance indicator in thermal systems. The Number of Transfer Units (NTU) method relates effectiveness to heat exchanger design parameters, such as surface area, heat capacity rates, and overall heat transfer coefficient, enabling precise prediction of exchanger efficiency. Understanding the relationship between NTU and effectiveness assists engineers in optimizing heat exchanger configurations for improved thermal performance and energy efficiency.

Fundamentals of Heat Exchanger Performance

Heat exchanger effectiveness measures the actual heat transfer relative to the maximum possible heat transfer, serving as a critical performance metric. The Number of Transfer Units (NTU) method provides a direct relationship between heat exchanger effectiveness and heat exchanger design, enabling accurate prediction of performance based on surface area, fluid flow rates, and heat transfer coefficients. Understanding the interdependence of NTU and effectiveness allows optimization of heat exchanger design for improved thermal efficiency and energy savings in various industrial applications.

Understanding the Number of Transfer Units (NTU)

The Number of Transfer Units (NTU) is a critical dimensionless parameter representing the efficiency of heat exchangers by quantifying the heat transfer capability relative to the heat capacity rate of the fluid. Heat exchanger effectiveness, defined as the ratio of actual heat transfer to maximum possible heat transfer, directly relates to NTU and the capacity rate ratio, enabling precise performance prediction. Understanding NTU allows engineers to design and assess heat exchangers by determining how effectively thermal energy is transferred under varying flow configurations and operating conditions.

Relationship Between NTU and Heat Exchanger Effectiveness

The relationship between the Number of Transfer Units (NTU) and heat exchanger effectiveness is crucial for evaluating heat exchanger performance, where effectiveness increases as NTU rises. Effectiveness, defined as the ratio of actual heat transfer to the maximum possible heat transfer, directly depends on NTU and the heat capacity rate ratio of the fluids involved. Analytical models and charts depicting effectiveness versus NTU enable engineers to optimize heat exchanger designs by balancing thermal efficiency and size constraints.

Methods for Calculating Heat Exchanger Effectiveness

Heat exchanger effectiveness can be calculated using methods such as the Number of Transfer Units (NTU) approach, which relates the heat exchanger's size and heat transfer coefficient to its performance. The NTU method provides a more detailed analysis by considering the heat capacity rates of the fluids and calculating effectiveness as a function of NTU and the heat capacity rate ratio. Other methods include the Log Mean Temperature Difference (LMTD) approach, primarily used when inlet and outlet temperatures are known, but the NTU method is preferred for design and performance evaluation in variable operating conditions.

Factors Affecting NTU and Effectiveness

Heat exchanger effectiveness depends on the thermal capacity rates and heat transfer characteristics, with the Number of Transfer Units (NTU) playing a pivotal role in quantifying the heat exchanger's performance. Factors affecting NTU include the overall heat transfer coefficient, heat exchanger surface area, and fluid flow rates, while effectiveness varies with flow arrangement such as counterflow, parallel flow, or crossflow configurations. Material properties, temperature differences, and fouling also significantly influence both NTU and effectiveness by altering heat transfer efficiency and thermal resistance.

Types of Heat Exchangers and Impact on Effectiveness

Shell-and-tube, plate, and finned-tube heat exchangers exhibit varying heat exchanger effectiveness based on their surface area and flow arrangements, with shell-and-tube typically achieving moderate effectiveness due to complex flow patterns. The Number of Transfer Units (NTU) method quantitatively evaluates heat exchanger performance by relating the heat capacity rate to the overall heat transfer coefficient and surface area, directly influencing effectiveness across types. Plate heat exchangers generally achieve higher effectiveness values because of their large surface area and counterflow arrangement, while finned-tube exchangers enhance effectiveness by increasing convective heat transfer through extended surfaces and turbulence promotion.

Practical Examples: NTU vs. Effectiveness Charts

Heat exchanger effectiveness quantifies the efficiency of heat transfer between fluids, directly influenced by the Number of Transfer Units (NTU), a dimensionless parameter representing heat exchanger size relative to fluid capacity rates. Practical examples utilize NTU vs. effectiveness charts to quickly estimate performance for various heat exchanger types, such as counterflow, parallel flow, and crossflow configurations, by mapping NTU values against temperature effectiveness. These charts help engineers optimize design and operational parameters by providing visual insights into the relationship between heat exchanger geometry, flow arrangement, and achievable thermal performance.

Design Implications of NTU-Effectiveness Analysis

Heat exchanger effectiveness correlates directly with the Number of Transfer Units (NTU), where higher NTU values typically indicate greater heat transfer efficiency. Design implications of NTU-effectiveness analysis reveal that increasing surface area, enhancing heat transfer coefficients, or optimizing fluid flow arrangements can significantly improve NTU and thus effectiveness. Accurate NTU-effectiveness modeling enables engineers to predict thermal performance and size heat exchangers properly to meet specific operational requirements while minimizing costs and energy consumption.

Optimizing Heat Exchanger Performance Using NTU and Effectiveness

Optimizing heat exchanger performance relies on understanding the relationship between heat exchanger effectiveness (e) and the Number of Transfer Units (NTU), where effectiveness measures the actual heat transfer relative to the maximum possible heat transfer. The NTU method provides a quantitative basis for evaluating the performance by correlating NTU values with effectiveness for various flow arrangements, enabling precise design adjustments. By maximizing NTU and targeting corresponding effectiveness curves, engineers can enhance thermal efficiency, reduce energy consumption, and improve overall system reliability.

Heat exchanger effectiveness and Number of Transfer Units (NTU) Infographic

libterm.com

libterm.com