Emulsification is the process of mixing two immiscible liquids, such as oil and water, to create a stable blend called an emulsion. This technique is crucial in industries like food, cosmetics, and pharmaceuticals to improve texture, stability, and shelf life of products. Discover how emulsification affects your daily products and why it matters by reading the full article.

Table of Comparison

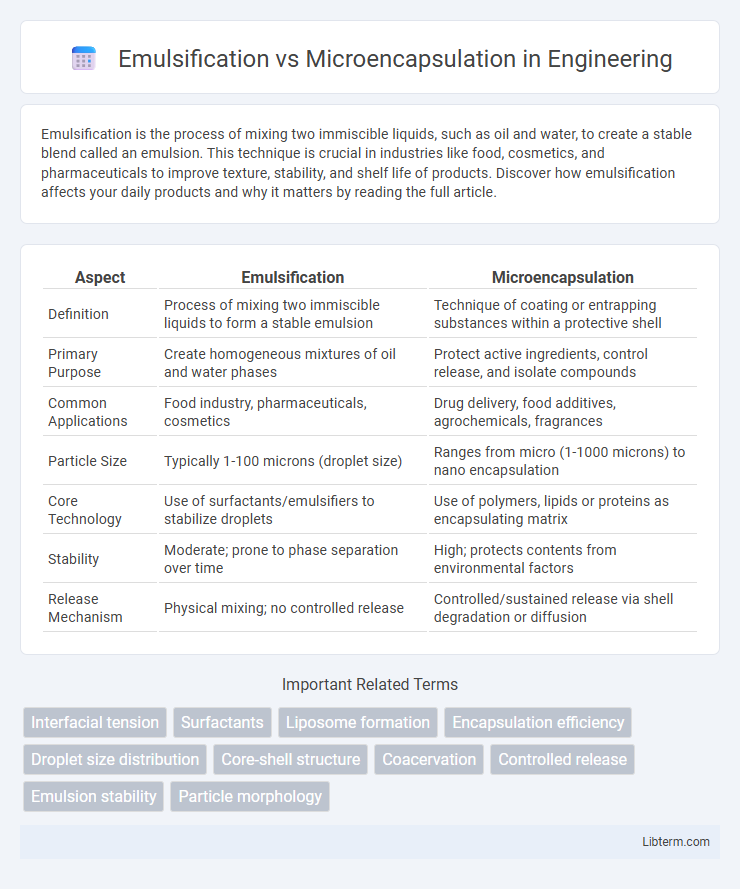

| Aspect | Emulsification | Microencapsulation |

|---|---|---|

| Definition | Process of mixing two immiscible liquids to form a stable emulsion | Technique of coating or entrapping substances within a protective shell |

| Primary Purpose | Create homogeneous mixtures of oil and water phases | Protect active ingredients, control release, and isolate compounds |

| Common Applications | Food industry, pharmaceuticals, cosmetics | Drug delivery, food additives, agrochemicals, fragrances |

| Particle Size | Typically 1-100 microns (droplet size) | Ranges from micro (1-1000 microns) to nano encapsulation |

| Core Technology | Use of surfactants/emulsifiers to stabilize droplets | Use of polymers, lipids or proteins as encapsulating matrix |

| Stability | Moderate; prone to phase separation over time | High; protects contents from environmental factors |

| Release Mechanism | Physical mixing; no controlled release | Controlled/sustained release via shell degradation or diffusion |

Understanding Emulsification: Definition and Principles

Emulsification is the process of mixing two immiscible liquids, typically oil and water, to form a stable dispersion called an emulsion, achieved through mechanical agitation and the use of emulsifiers that reduce interfacial tension. The principles of emulsification involve creating small droplets of one liquid dispersed within another, stabilized by surfactants or emulsifying agents that prevent coalescence by forming a protective barrier around droplets. Understanding emulsification is crucial in industries like food, pharmaceuticals, and cosmetics, where controlling droplet size and stability impacts product texture, shelf life, and bioavailability.

What is Microencapsulation? Core Concepts

Microencapsulation is a process that entraps active ingredients within a protective coating to form small capsules, enhancing stability and controlled release. This technique involves core materials such as oils, flavors, or pharmaceuticals surrounded by a polymeric shell, enabling targeted delivery and protection from environmental factors. Key concepts include encapsulation efficiency, particle size distribution, and shell permeability, which influence the release profile and functionality of the encapsulated substance.

Key Differences Between Emulsification and Microencapsulation

Emulsification involves mixing two immiscible liquids to form a stable dispersion, primarily used for creating fine droplets in food and pharmaceutical products. Microencapsulation entraps active ingredients within a coating material to protect and control their release in applications such as drug delivery and flavor preservation. The key differences lie in their purpose, with emulsification focusing on creating uniform mixtures, while microencapsulation provides targeted protection and controlled release of encapsulated substances.

Applications of Emulsification in Food and Pharmaceuticals

Emulsification plays a critical role in food and pharmaceutical industries by enabling the stable mixing of immiscible liquids, such as oil and water, to improve texture, flavor, and bioavailability of active compounds. In food products, emulsification enhances the consistency and shelf-life of dressings, sauces, and dairy alternatives, while in pharmaceuticals, it facilitates controlled drug delivery and improved absorption of lipophilic drugs. Emulsion-based formulations like nanoemulsions and microemulsions are widely used for targeted nutrient delivery, vaccine development, and encapsulating sensitive bioactive ingredients.

Industrial Uses of Microencapsulation Techniques

Microencapsulation techniques are extensively employed in the pharmaceutical, food, and cosmetic industries for controlled release and protection of active ingredients such as drugs, flavors, and vitamins. These methods enhance product stability, mask unpleasant tastes or odors, and improve bioavailability by encapsulating core materials within protective coatings. Unlike emulsification, which primarily disperses one liquid phase into another, microencapsulation provides more precise control over particle size and release mechanisms, making it ideal for industrial applications requiring targeted delivery and prolonged shelf life.

Advantages and Limitations of Emulsification

Emulsification offers advantages such as improved bioavailability of hydrophobic compounds, ease of large-scale production, and the ability to create stable dispersions for food, pharmaceutical, and cosmetic applications. Limitations include sensitivity to environmental factors like pH, temperature, and ionic strength, which can lead to phase separation or droplet coalescence, reducing stability. Emulsions typically have lower protection against oxidation and limited control over release compared to microencapsulation techniques.

Benefits and Challenges of Microencapsulation

Microencapsulation offers superior protection of sensitive ingredients by creating a physical barrier that prevents oxidation, moisture, and light degradation, enhancing shelf life and controlled release in food and pharmaceutical applications. Emulsification, while effective for mixing immiscible liquids, often lacks the prolonged stability and targeted delivery capabilities provided by microencapsulation. Challenges of microencapsulation include high production costs, complexity in scaling up processes, and potential issues with encapsulant compatibility, which require precise formulation to maintain efficacy and release profiles.

Techniques and Technologies Used in Emulsification

Emulsification techniques primarily include high-pressure homogenization, ultrasonic emulsification, and microfluidization, which use mechanical forces to disperse one liquid phase into another, forming stable emulsions. Technologies such as rotor-stator systems and membrane emulsification offer controlled droplet size and distribution to enhance emulsion stability and functionality. Advanced methods like phase inversion temperature (PIT) and spontaneous emulsification leverage temperature changes and solvent diffusion to create fine emulsions without intensive mechanical energy.

Microencapsulation Methods: Spray Drying, Coacervation, and More

Microencapsulation methods such as spray drying, coacervation, fluidized bed coating, and liposome entrapment play a crucial role in protecting active ingredients and controlling their release. Spray drying is widely used for its cost-effectiveness and scalability, creating dry powder microcapsules by atomizing a liquid feed into a hot drying chamber. Coacervation involves phase separation of polymers to form a coating around core materials, offering precise control over capsule size and wall thickness for sensitive bioactives.

Choosing the Right Encapsulation Method for Your Application

Selecting the right encapsulation method depends on the desired release profile, stability, and application compatibility. Emulsification excels in creating uniform droplets for controlled release in food and cosmetic products, while microencapsulation offers enhanced protection and targeted delivery in pharmaceuticals and agriculture. Consider factors like particle size, encapsulant materials, and environmental conditions to optimize performance and efficacy.

Emulsification Infographic

libterm.com

libterm.com