Automatic control systems regulate processes without human intervention by using feedback loops to maintain desired performance. These systems are essential in industries such as manufacturing, robotics, and aerospace, ensuring efficiency and safety through precise adjustments. Discover how automatic control can optimize your operations by exploring the detailed insights ahead.

Table of Comparison

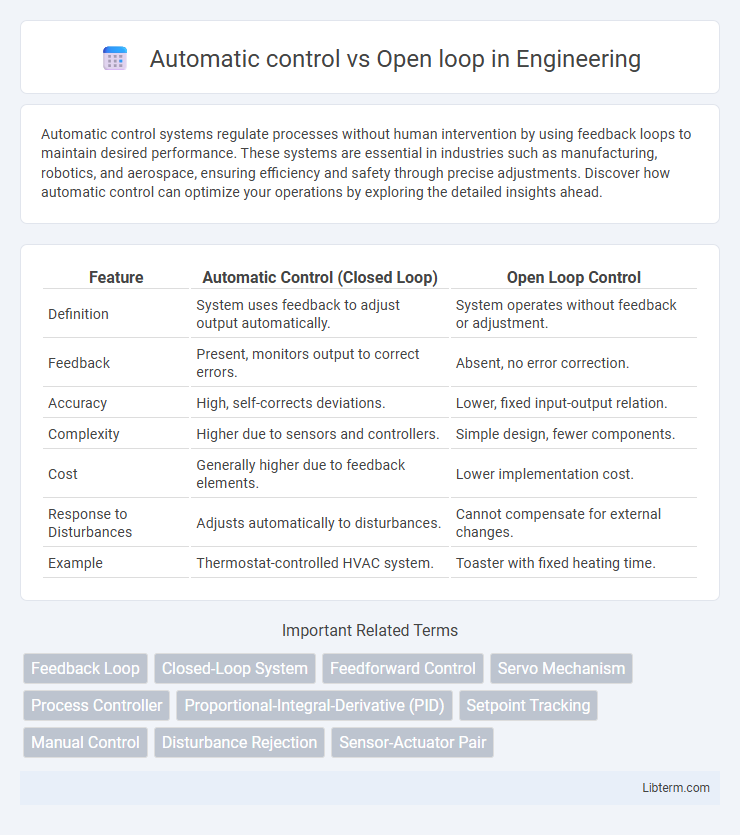

| Feature | Automatic Control (Closed Loop) | Open Loop Control |

|---|---|---|

| Definition | System uses feedback to adjust output automatically. | System operates without feedback or adjustment. |

| Feedback | Present, monitors output to correct errors. | Absent, no error correction. |

| Accuracy | High, self-corrects deviations. | Lower, fixed input-output relation. |

| Complexity | Higher due to sensors and controllers. | Simple design, fewer components. |

| Cost | Generally higher due to feedback elements. | Lower implementation cost. |

| Response to Disturbances | Adjusts automatically to disturbances. | Cannot compensate for external changes. |

| Example | Thermostat-controlled HVAC system. | Toaster with fixed heating time. |

Introduction to Automatic Control and Open Loop Systems

Automatic control systems regulate processes by continuously monitoring output and adjusting inputs to maintain desired performance, enhancing precision and stability. In contrast, open loop systems operate without feedback, applying fixed inputs regardless of output changes, making them simpler but less adaptive to disturbances. Understanding the fundamental differences between automatic control and open loop systems is crucial for designing efficient and responsive control architectures in engineering applications.

Fundamental Concepts of Control Systems

Automatic control systems regulate processes by continuously monitoring output to adjust inputs, ensuring desired performance despite disturbances or parameter variations. In contrast, open loop control operates without feedback, applying fixed inputs without correcting errors or responding to changes. The fundamental concept of control systems hinges on feedback mechanisms that enable automatic control to maintain system stability and accuracy.

Defining Open Loop Control Systems

Open loop control systems operate without feedback, relying solely on predefined input commands to control a process or device. These systems do not monitor output performance, making them susceptible to errors caused by disturbances or system variations. Automatic control systems contrast with open loop designs by continuously adjusting based on feedback to maintain desired performance.

Defining Automatic (Closed Loop) Control Systems

Automatic (closed loop) control systems continuously monitor output variables using feedback sensors to adjust inputs and maintain desired performance, ensuring precision and stability. Unlike open loop systems that operate without feedback, closed loop control dynamically corrects errors caused by disturbances or system variations. This real-time feedback mechanism enhances accuracy and reliability in applications such as temperature regulation, motor speed control, and industrial automation.

Key Components and Mechanisms

Automatic control systems rely on sensors, controllers, and actuators to continuously monitor and adjust the process variables, ensuring the desired output through feedback mechanisms. Open loop systems operate without feedback, relying solely on predefined inputs and control actions without correcting deviations or disturbances. The key components in automatic control are feedback sensors and error detectors, while open loop control primarily depends on fixed input signals and actuators without any feedback element.

Advantages of Open Loop Control

Open loop control systems offer simplicity and cost-effectiveness by eliminating the need for feedback mechanisms, resulting in faster response times. These systems require less computational power and are easier to design and maintain, making them ideal for applications with predictable and stable processes. Open loop control is advantageous in environments where precision feedback is unnecessary, reducing complexity and potential points of failure.

Advantages of Automatic Control

Automatic control systems offer improved accuracy and consistency by continuously monitoring and adjusting processes based on real-time feedback. They enhance system stability and reduce human error, leading to increased efficiency and safety in industrial applications. Unlike open-loop systems, automatic control adapts to disturbances and changes in the environment, ensuring optimal performance under varying conditions.

Limitations and Challenges of Each System

Automatic control systems face limitations such as sensitivity to model inaccuracies and external disturbances, which can cause instability or degraded performance. Open loop systems, while simpler and cost-effective, lack feedback mechanisms, making them unable to correct errors or adapt to unexpected changes, resulting in poor precision and reliability. Both systems encounter challenges in handling nonlinearities and dynamic variations in real-world applications, necessitating careful design and tuning.

Real-World Applications and Use Cases

Automatic control systems are essential in real-world applications such as manufacturing process automation, where feedback loops adjust machinery operations for precision and efficiency. Open loop control systems are commonly used in simple tasks like household appliance timers or irrigation systems, where no feedback is required for operation. Industries such as automotive cruise control and HVAC systems rely heavily on automatic control for maintaining desired output despite external disturbances.

Choosing the Right System: Factors to Consider

Selecting between automatic control and open loop systems depends on factors such as system accuracy, feedback requirements, and environmental variability. Automatic control systems excel in maintaining desired outputs through continuous feedback and adjustment, ideal for processes with fluctuating conditions. Open loop systems suit applications with predictable inputs and minimal disturbances, offering simplicity and lower cost but less precision.

Automatic control Infographic

libterm.com

libterm.com