Adaptive control dynamically adjusts system parameters to maintain optimal performance despite changing conditions and uncertainties. This approach is essential for applications where fixed control methods fail to cope with nonlinearities or external disturbances. Discover how adaptive control can enhance your system's efficiency and reliability by exploring the detailed insights in the article.

Table of Comparison

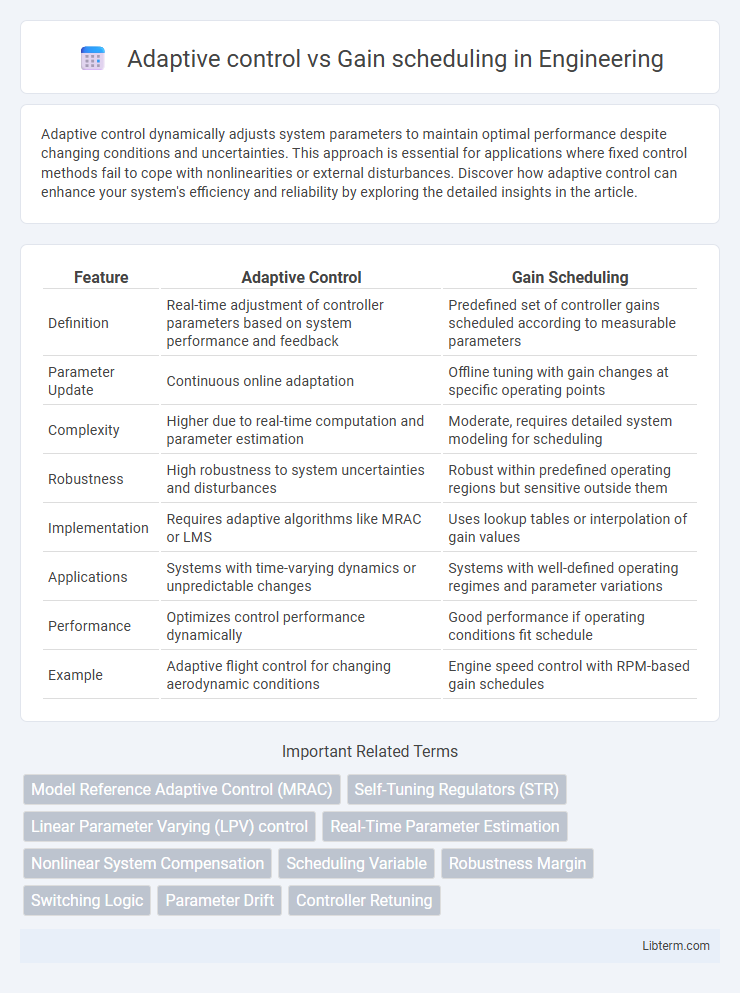

| Feature | Adaptive Control | Gain Scheduling |

|---|---|---|

| Definition | Real-time adjustment of controller parameters based on system performance and feedback | Predefined set of controller gains scheduled according to measurable parameters |

| Parameter Update | Continuous online adaptation | Offline tuning with gain changes at specific operating points |

| Complexity | Higher due to real-time computation and parameter estimation | Moderate, requires detailed system modeling for scheduling |

| Robustness | High robustness to system uncertainties and disturbances | Robust within predefined operating regions but sensitive outside them |

| Implementation | Requires adaptive algorithms like MRAC or LMS | Uses lookup tables or interpolation of gain values |

| Applications | Systems with time-varying dynamics or unpredictable changes | Systems with well-defined operating regimes and parameter variations |

| Performance | Optimizes control performance dynamically | Good performance if operating conditions fit schedule |

| Example | Adaptive flight control for changing aerodynamic conditions | Engine speed control with RPM-based gain schedules |

Introduction to Adaptive Control and Gain Scheduling

Adaptive control continuously adjusts controller parameters in real-time to maintain optimal system performance under varying conditions, making it ideal for complex, uncertain environments. Gain scheduling employs a pre-determined set of controller gains based on measurable operating conditions, offering simplicity but limited flexibility for nonlinear systems. Both techniques address system variations, with adaptive control providing dynamic adaptability and gain scheduling relying on predefined gain sets.

Fundamental Concepts of Adaptive Control

Adaptive control adjusts controller parameters in real-time based on system behavior to maintain optimal performance despite uncertainties or changes in the plant. It relies on parameter estimation algorithms and feedback mechanisms to identify and compensate for dynamic variations, enabling continuous adaptation without predefined operating points. In contrast, gain scheduling uses a set of fixed controllers interpolated across known operating conditions, lacking the flexibility to respond autonomously to unmodeled disturbances.

Key Principles of Gain Scheduling

Gain scheduling relies on predefined controller parameters adjusted according to measurable operating conditions or system states to maintain performance across varying dynamics. It partitions the operating range into regions, each with a fixed controller designed based on linearized models at specific points. This approach assumes smooth parameter variations and requires accurate system modeling to ensure stability and optimal control performance throughout the scheduled gains.

Advantages of Adaptive Control

Adaptive control offers real-time system parameter adjustment, providing superior performance under varying and uncertain conditions compared to gain scheduling. It eliminates the need for extensive pre-defined operating points, resulting in enhanced flexibility and robustness in dynamic environments. Adaptive control effectively handles nonlinearities and external disturbances, improving overall system stability and responsiveness.

Benefits of Gain Scheduling Techniques

Gain scheduling techniques optimize controller performance by adjusting control parameters based on measurable operating conditions, ensuring robust stability across varying system dynamics. This approach effectively handles nonlinearities by interpolating between pre-designed linear controllers at different operating points, enhancing system responsiveness and reducing the need for complex real-time computations. The method's simplicity and reliability make it particularly advantageous in aerospace and process control applications where precise adaptation to changing environments is critical.

Limitations of Adaptive Control Systems

Adaptive control systems often face limitations such as slow convergence rates and instability under rapidly changing system dynamics or high uncertainty. These systems require extensive computational resources and may struggle with unmodeled nonlinearities or time delays, reducing their effectiveness in real-time applications. In contrast, gain scheduling offers a simpler implementation by adjusting controller parameters based on predefined operating points but lacks the flexibility to handle unpredictable variations.

Drawbacks of Gain Scheduling Approaches

Gain scheduling approaches often suffer from limited performance outside predefined operating points, as they rely heavily on accurate scheduling variables and extensive offline tuning. These methods can struggle with sudden system changes or nonlinearities that fall between scheduled parameters, leading to instability or degraded control quality. The complexity and maintenance costs increase significantly when managing numerous operating regions or adapting to system parameter variations in real time.

Application Areas: Adaptive Control vs Gain Scheduling

Adaptive control excels in dynamic environments with significant uncertainties such as aerospace systems, robotic manipulators, and process control where system parameters vary unpredictably. Gain scheduling is effective in applications with well-defined operating points like aircraft flight control, automotive engine management, and chemical reactors, where system behavior changes smoothly and can be pre-characterized. Both methods optimize performance, but adaptive control suits systems requiring real-time parameter adjustments, while gain scheduling relies on pre-designed controllers mapped to specific operating conditions.

Selection Criteria: Choosing the Right Strategy

Selection criteria for adaptive control versus gain scheduling depend on system variability and complexity; adaptive control suits systems with unknown or varying dynamics, offering real-time parameter adjustment. Gain scheduling is ideal for systems with well-defined operating points and predictable nonlinearities, using pre-designed controllers switched based on measurable variables. Consider computational resources, stability requirements, and ease of implementation when selecting between these strategies to optimize control performance.

Future Trends in Adaptive Control and Gain Scheduling

Future trends in adaptive control emphasize integration with machine learning algorithms to enhance real-time system identification and parameter adjustment, increasing robustness in dynamic environments. Gain scheduling advancements focus on developing more efficient interpolation techniques and adaptive parameter tuning to handle nonlinearities across broader operating ranges. Both approaches are converging towards hybrid frameworks that leverage data-driven models for improved precision and adaptability in complex control systems.

Adaptive control Infographic

libterm.com

libterm.com