Profile tolerance is a critical geometric control that defines the allowable variation in the surface outline of a part, ensuring functional fit and performance in assemblies. It helps maintain precise shape and size conformity, minimizing deviations that could affect product quality. Discover how mastering profile tolerance can improve your manufacturing accuracy by reading the rest of this article.

Table of Comparison

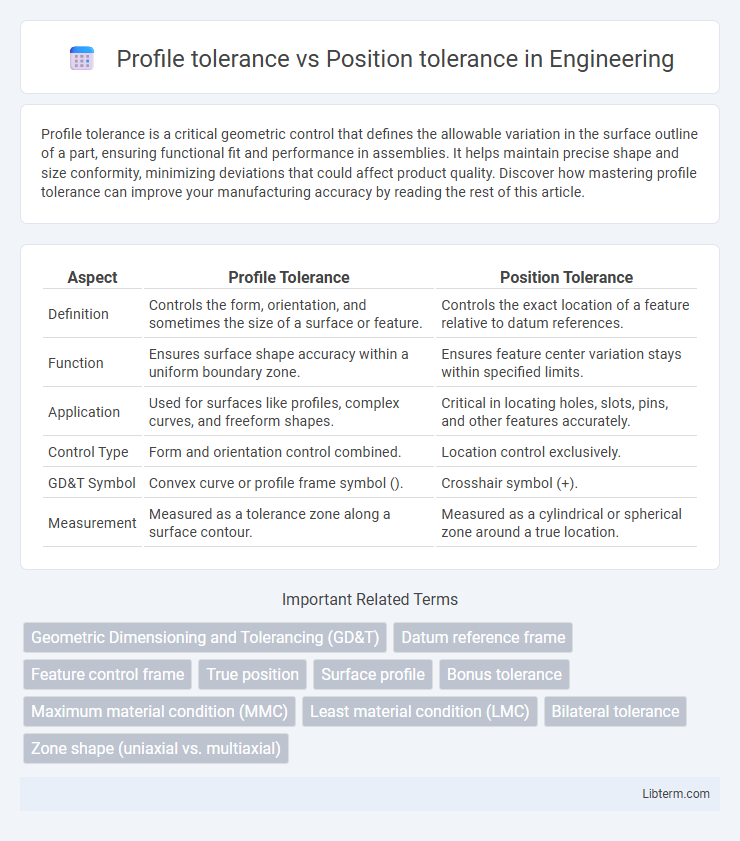

| Aspect | Profile Tolerance | Position Tolerance |

|---|---|---|

| Definition | Controls the form, orientation, and sometimes the size of a surface or feature. | Controls the exact location of a feature relative to datum references. |

| Function | Ensures surface shape accuracy within a uniform boundary zone. | Ensures feature center variation stays within specified limits. |

| Application | Used for surfaces like profiles, complex curves, and freeform shapes. | Critical in locating holes, slots, pins, and other features accurately. |

| Control Type | Form and orientation control combined. | Location control exclusively. |

| GD&T Symbol | Convex curve or profile frame symbol (). | Crosshair symbol (+). |

| Measurement | Measured as a tolerance zone along a surface contour. | Measured as a cylindrical or spherical zone around a true location. |

Introduction to Profile Tolerance and Position Tolerance

Profile tolerance controls the form, orientation, and sometimes the size of a surface or feature within specified limits, ensuring the surface geometry conforms to a 3D tolerance zone. Position tolerance specifically governs the exact location, orientation, and sometimes the size of a feature relative to datum references, ensuring precise placement within a defined cylindrical or spherical tolerance zone. Both tolerances are critical in geometric dimensioning and tolerancing (GD&T), with profile tolerance focusing on surface shape control and position tolerance emphasizing feature location accuracy.

Definitions: What is Profile Tolerance?

Profile tolerance defines a uniform boundary zone around a surface or feature within which the entire surface or feature must lie, ensuring precise shape and size control. It controls form, orientation, and sometimes location, allowing for variations as long as the surface remains within the specified tolerance zone. Commonly used in geometric dimensioning and tolerancing (GD&T), profile tolerance is essential for complex curved surfaces and intricate parts.

Definitions: What is Position Tolerance?

Position tolerance specifies the allowable variation in the location of a feature relative to its true position, ensuring precise alignment and assembly in manufacturing. It controls the geometric center, axis, or center plane of a feature within a defined tolerance zone. Unlike profile tolerance, which governs the overall shape and contour, position tolerance focuses specifically on the spatial accuracy of features such as holes, slots, or pins.

Fundamental Differences Between Profile and Position Tolerance

Profile tolerance controls the allowable variation of a surface's form, orientation, and location within a specified boundary zone, ensuring the entire surface conforms uniformly to the design shape. Position tolerance defines the permissible deviation of specific feature locations relative to a true datum reference, focusing solely on the exact placement accuracy of points, holes, or features. The fundamental difference lies in profile tolerance managing overall surface geometry, while position tolerance strictly governs the precise location of features.

Applications of Profile Tolerance in Engineering

Profile tolerance precisely controls the contour, surface, and form of intricate parts, ensuring consistent quality in aerospace and automotive components. It is essential for maintaining the exact shape of camshafts, turbine blades, and ergonomic housings where surface smoothness impacts performance and safety. Position tolerance primarily governs the location of features relative to datums, making profile tolerance the choice for complex geometries requiring uniformity in freeform surfaces.

Applications of Position Tolerance in Manufacturing

Position tolerance plays a crucial role in manufacturing by ensuring the precise location of holes, slots, and other features relative to datums, which is vital for assembly and functionality of components. It allows engineers to control the permissible deviation in the feature's geometric center, enhancing interchangeability and reducing the risk of assembly errors. Compared to profile tolerance, position tolerance is preferred in applications requiring exact feature placement, such as in automotive, aerospace, and machinery production, where tight control of fit and alignment directly impacts product performance.

Interpretation of Profile vs Position Tolerance in GD&T

Profile tolerance controls the uniformity and allowable variation of a surface's shape, ensuring the entire surface lies within a specified boundary zone relative to the true profile. Position tolerance locates a feature precisely within a tolerance zone, governing the exact location of holes or slots relative to datums. In GD&T interpretation, profile tolerance addresses form, orientation, and sometimes location, while position tolerance strictly governs the feature's location and perpendicularity accuracy.

Advantages and Limitations of Profile Tolerance

Profile tolerance provides precise control over the contour of a feature, allowing for uniform tolerance zones along complex surfaces, which enhances overall part quality and interchangeability. It offers advantages in reducing inspection complexity by applying a single tolerance to an entire surface, minimizing cumulative tolerances often seen in position tolerance. However, profile tolerance may lead to overly stringent requirements and increased manufacturing costs when applied unnecessarily, and its application can be less effective for features primarily defined by exact location rather than shape.

Advantages and Limitations of Position Tolerance

Position tolerance offers precise control over the location of features, ensuring functional assembly and interchangeability in complex mechanical parts, which enhances manufacturing accuracy. Its primary advantage lies in defining a tolerance zone that maintains the exactness of feature centers, critical for parts requiring tight assembly conditions. However, position tolerance can be more challenging to inspect and interpret compared to profile tolerance, often requiring specialized measurement equipment and techniques.

Selecting the Right Tolerance: Profile vs Position

Selecting the right tolerance depends on the geometric control requirements of the feature. Profile tolerance controls the form, orientation, and sometimes size of a surface, ensuring uniformity across its entire profile, while position tolerance strictly controls the exact location of features within specified limits. Use profile tolerance when surface shape consistency is critical, and position tolerance when the precise location relative to datums is essential for assembly or function.

Profile tolerance Infographic

libterm.com

libterm.com