Proportional-Integral (PI) control is a fundamental feedback mechanism used in industrial automation to maintain system stability and reduce steady-state error. By combining proportional response with integral action, it effectively corrects deviations in process variables for smoother and more accurate control. Explore the rest of the article to understand how PI control can optimize Your system's performance.

Table of Comparison

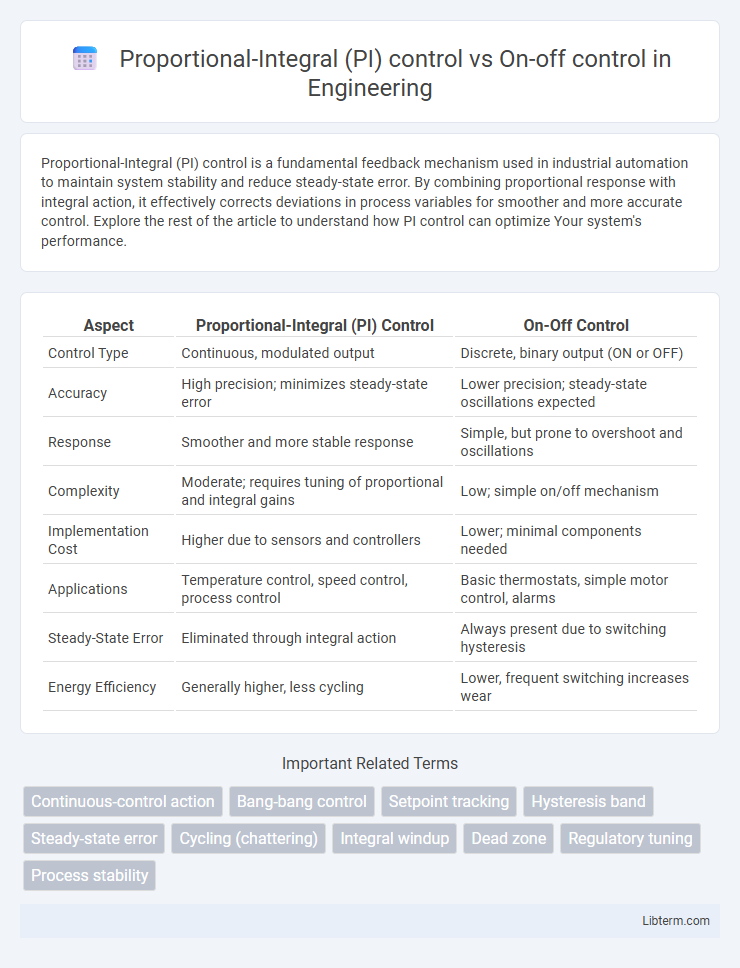

| Aspect | Proportional-Integral (PI) Control | On-Off Control |

|---|---|---|

| Control Type | Continuous, modulated output | Discrete, binary output (ON or OFF) |

| Accuracy | High precision; minimizes steady-state error | Lower precision; steady-state oscillations expected |

| Response | Smoother and more stable response | Simple, but prone to overshoot and oscillations |

| Complexity | Moderate; requires tuning of proportional and integral gains | Low; simple on/off mechanism |

| Implementation Cost | Higher due to sensors and controllers | Lower; minimal components needed |

| Applications | Temperature control, speed control, process control | Basic thermostats, simple motor control, alarms |

| Steady-State Error | Eliminated through integral action | Always present due to switching hysteresis |

| Energy Efficiency | Generally higher, less cycling | Lower, frequent switching increases wear |

Introduction to Control Systems

Proportional-Integral (PI) control enhances system stability by continuously adjusting the control output based on both the magnitude of the error and the accumulated past errors, reducing steady-state error and improving accuracy. On-off control operates by toggling the actuator fully on or off around a setpoint, which can cause oscillations and less precise control in dynamic systems. In control systems, PI control is preferred for processes requiring smooth and accurate regulation, while on-off control suits simpler applications with binary outputs or less stringent performance requirements.

Understanding On-Off Control

On-off control operates by switching the output fully on or off based on setpoint deviations, producing a simple binary response without intermediate states. This method is easy to implement and cost-effective but often leads to oscillations and less precise temperature or process regulation compared to proportional-integral (PI) control. Understanding on-off control is essential for applications where tight accuracy is less critical, and system simplicity or low cost is prioritized.

Fundamentals of Proportional-Integral (PI) Control

Proportional-Integral (PI) control combines proportional and integral actions to continuously correct the control error by adjusting the output based on both the magnitude and the accumulation of past errors, ensuring minimal steady-state error. Unlike On-off control, which toggles the actuator fully on or off, PI control provides smooth and precise regulation of process variables, reducing oscillations and improving stability. The integral component specifically eliminates residual steady-state offset that proportional control alone cannot remove, making PI control fundamental in industrial automation and process control systems.

Key Differences Between PI and On-Off Control

Proportional-Integral (PI) control continuously adjusts the output based on both the magnitude of the error and the accumulated past errors, ensuring precise and stable system response. On-off control operates by switching the output fully on or off based on predefined thresholds, leading to simple implementation but potential oscillations and less accuracy. PI control minimizes steady-state error and provides smoother control in comparison to the binary nature and inherent hysteresis of on-off control.

Response Time and System Stability

Proportional-Integral (PI) control provides faster response time and enhanced system stability by continuously adjusting output based on error accumulation, minimizing steady-state error and reducing oscillations. On-off control exhibits slower response time with frequent switching, leading to larger overshoot and potential system instability due to hysteresis and lack of proportional feedback. PI controllers are preferred in applications requiring precise regulation and smooth system behavior, while on-off control is suitable for simple, cost-effective systems with less stringent stability demands.

Energy Efficiency and Wear on Components

Proportional-Integral (PI) control enhances energy efficiency by continuously adjusting output to maintain optimal system performance, reducing power consumption fluctuations. On-off control often causes frequent cycling, leading to higher energy waste and increased mechanical wear on components due to repeated start-stop operations. PI control's smoother operation extends equipment lifespan by minimizing stress and reducing maintenance needs.

Application Scenarios for On-Off Control

On-off control is widely applied in simple systems requiring basic temperature regulation or pressure control, such as household thermostats and refrigerator compressors, where precision is less critical. This control method suits applications with mechanical or electrical systems that operate with distinct upper and lower thresholds, providing reliable and cost-effective switching without the complexity of continuous adjustment. On-off control excels in scenarios where system inertia and time delays are minimal, preventing excessive wear from frequent cycling and ensuring stable performance with straightforward implementation.

Application Scenarios for PI Control

PI control excels in applications requiring precise and stable regulation of temperature, pressure, or speed, such as in chemical reactors, HVAC systems, and motor drives. Its ability to minimize steady-state error and smoothly adjust output makes it ideal for processes with slow dynamics or where overshoot must be avoided. Compared to on-off control, PI control enhances system performance in continuous process industries by reducing oscillations and improving energy efficiency.

Advantages and Limitations of Each Method

Proportional-Integral (PI) control offers precise regulation by continuously adjusting output to minimize steady-state error and improve system stability, making it ideal for processes requiring smooth and accurate control. On-off control is simpler and cost-effective, suitable for systems where binary operation suffices, but it often leads to oscillations and less precise output due to its hysteresis behavior. While PI control demands more complex tuning and computational resources, on-off control excels in robustness and ease of implementation for less dynamic systems.

Choosing the Right Control Strategy

Selecting between Proportional-Integral (PI) control and On-off control depends on system requirements for precision and stability. PI control offers continuous adjustment, minimizing steady-state error in temperature or speed regulation, making it ideal for processes demanding fine control and smooth responses. On-off control suits simpler applications with less precision needs, where switching between fully on and off states suffices, such as basic thermostats or pump controls.

Proportional-Integral (PI) control Infographic

libterm.com

libterm.com