Just-in-Time (JIT) and Materials Requirement Planning (MRP) are essential inventory management systems designed to optimize production efficiency and reduce waste. JIT focuses on minimizing inventory levels by receiving goods only as needed in the production process, while MRP uses detailed scheduling and demand forecasting to ensure materials are available for manufacturing. Explore this article to understand how these approaches can improve your supply chain and production workflow.

Table of Comparison

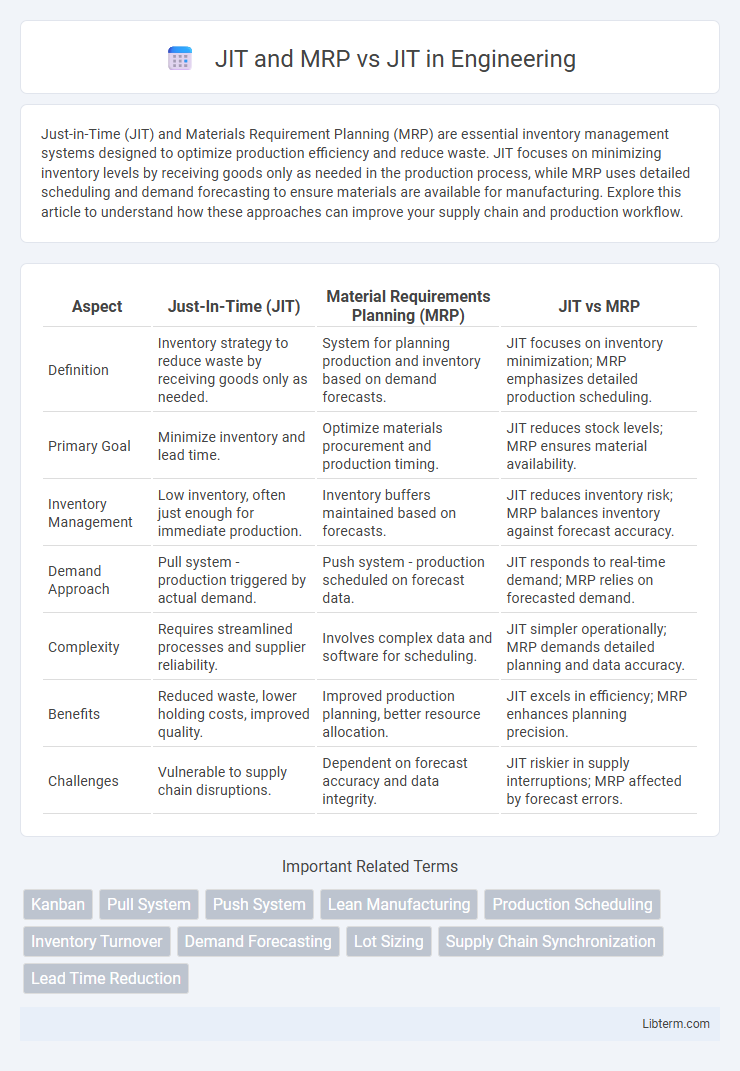

| Aspect | Just-In-Time (JIT) | Material Requirements Planning (MRP) | JIT vs MRP |

|---|---|---|---|

| Definition | Inventory strategy to reduce waste by receiving goods only as needed. | System for planning production and inventory based on demand forecasts. | JIT focuses on inventory minimization; MRP emphasizes detailed production scheduling. |

| Primary Goal | Minimize inventory and lead time. | Optimize materials procurement and production timing. | JIT reduces stock levels; MRP ensures material availability. |

| Inventory Management | Low inventory, often just enough for immediate production. | Inventory buffers maintained based on forecasts. | JIT reduces inventory risk; MRP balances inventory against forecast accuracy. |

| Demand Approach | Pull system - production triggered by actual demand. | Push system - production scheduled on forecast data. | JIT responds to real-time demand; MRP relies on forecasted demand. |

| Complexity | Requires streamlined processes and supplier reliability. | Involves complex data and software for scheduling. | JIT simpler operationally; MRP demands detailed planning and data accuracy. |

| Benefits | Reduced waste, lower holding costs, improved quality. | Improved production planning, better resource allocation. | JIT excels in efficiency; MRP enhances planning precision. |

| Challenges | Vulnerable to supply chain disruptions. | Dependent on forecast accuracy and data integrity. | JIT riskier in supply interruptions; MRP affected by forecast errors. |

Introduction to JIT and MRP

Just-In-Time (JIT) is a production strategy focused on reducing inventory costs by receiving goods only as they are needed in the manufacturing process, enhancing efficiency and minimizing waste. Material Requirements Planning (MRP) is a system that manages manufacturing processes by calculating material needs based on production schedules and inventory levels, ensuring timely availability of raw materials. While JIT emphasizes lean inventory and quick response to demand changes, MRP prioritizes detailed planning and scheduling to optimize resource allocation and production flow.

Defining Just-in-Time (JIT)

Just-in-Time (JIT) is an inventory management strategy that minimizes stock levels by synchronizing production schedules with demand to reduce waste and increase efficiency. Unlike Material Requirements Planning (MRP), which relies on detailed forecasts and fixed lead times to plan inventory replenishment, JIT emphasizes real-time demand signals for producing only what is needed when it is needed. This approach enhances cash flow, reduces carrying costs, and promotes lean manufacturing principles.

Understanding Material Requirements Planning (MRP)

Material Requirements Planning (MRP) is a systematic approach that calculates material needs based on production schedules, inventory levels, and lead times, ensuring timely procurement and minimizing stockouts. Unlike Just-In-Time (JIT), which focuses on reducing inventory by receiving materials only as needed, MRP uses detailed demand forecasting to plan material availability. Integrating MRP with JIT can enhance production efficiency by balancing inventory control with precise material scheduling.

Key Principles of JIT

Just-In-Time (JIT) focuses on minimizing inventory by producing goods only as needed, reducing waste and improving efficiency through continuous flow and pull systems. Key principles of JIT include zero inventory, continuous improvement (Kaizen), and high-quality production with minimal defects. In contrast, Material Requirements Planning (MRP) relies on forecast-based scheduling and inventory buffers, making JIT preferable for lean manufacturing environments seeking reduced lead times and enhanced responsiveness.

Main Features of MRP

Material Requirements Planning (MRP) systems focus on inventory control, production scheduling, and demand forecasting by using a detailed bill of materials, inventory status, and master production schedule to calculate material requirements and order dates. Just-in-Time (JIT) emphasizes minimizing inventory levels and reducing waste by producing goods only as needed based on actual demand. Unlike JIT, MRP allows for planned inventory buffers and complex scheduling to balance supply and demand in environments with variable lead times and fluctuating orders.

Comparison: JIT vs. MRP

Just-In-Time (JIT) emphasizes inventory reduction by receiving materials only as needed in the production process, minimizing storage costs and waste. Material Requirements Planning (MRP) focuses on scheduling and planning inventory based on forecasted demand and lead times to ensure material availability. JIT excels in reducing inventory and increasing responsiveness, while MRP provides detailed planning for complex manufacturing environments with variable demand.

Advantages of Implementing JIT

Just-In-Time (JIT) inventory management reduces waste and lowers inventory holding costs by synchronizing production with demand, ensuring materials arrive only as needed. Unlike Material Requirements Planning (MRP), which relies heavily on forecasts and scheduled orders, JIT enhances efficiency through real-time supplier coordination and streamlined workflows. Implementing JIT leads to improved cash flow, minimized storage space, and increased responsiveness to market changes.

Benefits and Limitations of MRP

Material Requirements Planning (MRP) enhances inventory management by calculating precise component needs and scheduling, reducing stockouts and production delays. However, MRP systems rely heavily on accurate input data, and errors or outdated information can lead to excess inventory or shortages. Unlike Just-In-Time (JIT), which minimizes inventory by synchronizing production with demand, MRP offers better planning for complex manufacturing processes but may incur higher holding costs and less responsiveness to sudden demand changes.

When to Choose JIT Over MRP

Choosing JIT over MRP is ideal when demand is stable and predictable, allowing minimal inventory levels and reducing waste through continuous workflow. JIT excels in environments emphasizing lean manufacturing, short lead times, and strong supplier relationships to ensure timely material delivery. In contrast, MRP suits complex production schedules with variable demand, but JIT drives efficiency by synchronizing production strictly with actual customer orders.

JIT and MRP: Integration Possibilities

Just-in-Time (JIT) and Material Requirements Planning (MRP) systems can be integrated to enhance production efficiency by combining JIT's lean inventory control with MRP's demand forecasting and scheduling capabilities. This integration allows manufacturers to reduce inventory holding costs while ensuring materials are available for production, improving responsiveness to market fluctuations. Advanced ERP systems facilitate this synergy by synchronizing real-time data from both JIT and MRP processes, optimizing supply chain management and production planning.

JIT and MRP Infographic

libterm.com

libterm.com