Human-Machine Interface (HMI) technology enables efficient communication between operators and machines, streamlining industrial processes and improving productivity. Advanced HMI systems integrate touchscreens, graphical displays, and user-friendly controls to enhance operational accuracy and reduce errors. Discover how upgrading your HMI solutions can transform workflow and optimize system performance in the rest of this article.

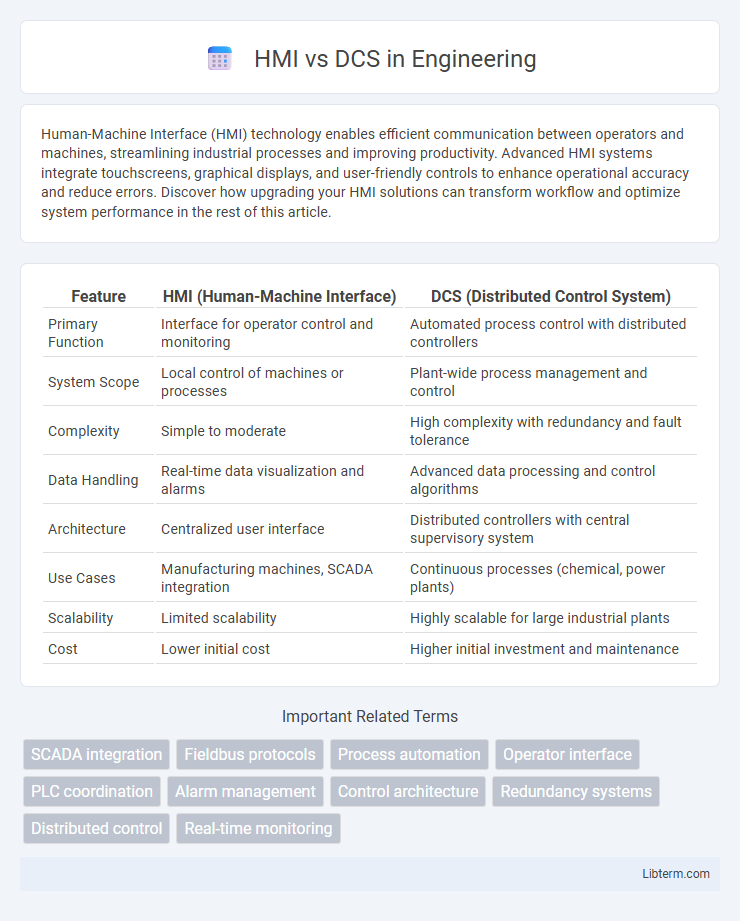

Table of Comparison

| Feature | HMI (Human-Machine Interface) | DCS (Distributed Control System) |

|---|---|---|

| Primary Function | Interface for operator control and monitoring | Automated process control with distributed controllers |

| System Scope | Local control of machines or processes | Plant-wide process management and control |

| Complexity | Simple to moderate | High complexity with redundancy and fault tolerance |

| Data Handling | Real-time data visualization and alarms | Advanced data processing and control algorithms |

| Architecture | Centralized user interface | Distributed controllers with central supervisory system |

| Use Cases | Manufacturing machines, SCADA integration | Continuous processes (chemical, power plants) |

| Scalability | Limited scalability | Highly scalable for large industrial plants |

| Cost | Lower initial cost | Higher initial investment and maintenance |

Understanding HMI and DCS: Basic Definitions

Human-Machine Interface (HMI) is a user interface that connects operators to machinery or industrial systems through graphical displays and control inputs, enabling real-time monitoring and manual control. Distributed Control System (DCS) is an automated control system that manages complex industrial processes by distributing control functions across multiple interconnected controllers, ensuring high reliability and scalability. Understanding the basic definitions highlights that HMI serves as an operator's visualization and interaction tool, while DCS integrates control logic and automation for process optimization.

Core Functions of HMI Systems

HMI (Human-Machine Interface) systems primarily focus on providing intuitive graphical visualization and real-time data interaction, enabling operators to monitor and control industrial processes efficiently. Core functions include alarm management, trend analysis, and user access control, enhancing situational awareness and decision-making capabilities. Unlike DCS (Distributed Control Systems), which integrate control logic and automation, HMIs serve as the operator interface layer, emphasizing usability and data representation.

Core Functions of DCS Systems

Distributed Control Systems (DCS) core functions include process control, data acquisition, and system integration, enabling real-time monitoring and automation of complex industrial processes. DCS platforms provide centralized control with distributed intelligence, ensuring robust fault tolerance and scalability. Key capabilities involve continuous process optimization, alarm management, and seamless communication between field devices and control centers to enhance operational efficiency.

Key Differences Between HMI and DCS

HMI (Human-Machine Interface) serves as the graphical interface for operators to monitor and control industrial processes, while DCS (Distributed Control System) is a comprehensive control architecture managing entire process automation through distributed controllers. The key difference lies in HMI's role as a user interface component, whereas DCS integrates both control and execution layers, enabling process control, data acquisition, and real-time automation. DCS systems provide advanced control algorithms and redundancy for critical applications, whereas HMIs focus on visualization, alarm management, and user interaction capabilities.

System Architecture: HMI vs DCS

Human-Machine Interface (HMI) systems primarily serve as user-centric dashboards that enable operators to visualize, control, and interact with individual machines or processes via graphical displays. Distributed Control Systems (DCS) feature a hierarchical system architecture with centralized control units distributing control tasks to multiple embedded controllers across different plant sections, ensuring comprehensive process automation and reliability. HMI functions as the operator's gateway, while DCS integrates control logic, communication networks, and supervisory functions within a scalable and redundant framework.

Scalability and Flexibility Comparison

HMI systems offer scalable interface solutions tailored for operator control and monitoring across various plant sizes, but they primarily focus on visualization rather than detailed process control. DCS systems provide greater scalability and flexibility through integrated control, automation, and real-time data processing, supporting complex industrial processes and expanding control loops seamlessly. The inherent modular design of DCS allows for easier upgrades and expansion, making it more suitable for large-scale, dynamic environments compared to HMI standalone implementations.

Integration and Compatibility Considerations

HMI systems offer flexible visualization and control interfaces compatible with various PLCs, facilitating seamless operator interaction across distributed equipment. DCS platforms provide integrated control and automation with centralized data management, inherently designed for advanced process synchronization and fault tolerance. Integration requires assessing communication protocols, real-time data exchange capabilities, and scalability to ensure interoperability between diverse hardware and software environments.

Security Implications: HMI vs DCS

Human-Machine Interfaces (HMI) and Distributed Control Systems (DCS) differ significantly in security implications, with DCS offering enhanced resilience due to its decentralized architecture that limits single points of failure and contains cyber threats within localized segments. HMI systems, often serving as centralized points of interaction, present higher vulnerability to cyber-attacks, requiring robust authentication, encryption, and continuous monitoring to safeguard against unauthorized access and data breaches. Understanding these distinctions is critical for implementing effective cybersecurity strategies tailored to the control environment, ensuring operational continuity and protection of critical infrastructure.

Cost Analysis: Initial and Long-term Investments

HMI systems generally have lower initial costs due to simpler interfaces and hardware requirements, making them suitable for small to medium-scale operations. DCS setups involve higher upfront investments from complex hardware integration and extensive software licensing but offer greater scalability and automation capabilities that reduce operational expenses over time. Long-term costs for DCS tend to be lower when factoring in enhanced system reliability, reduced downtime, and advanced process control efficiency compared to HMI systems.

Choosing the Right Solution: HMI or DCS?

Choosing the right solution between HMI and DCS depends on the scale and complexity of the industrial process; HMI is ideal for localized control with operator interaction, while DCS offers integrated, distributed control for large-scale operations requiring seamless communication and automation. Industries with high-volume production and multiple control loops benefit from DCS due to its robust fault tolerance and centralized monitoring capabilities. For smaller plants or systems needing user-friendly interfaces and real-time data visualization, an HMI provides a cost-effective, flexible solution that enhances operator efficiency.

HMI Infographic

libterm.com

libterm.com