Jib cranes provide versatile lifting solutions in industrial and construction settings, featuring a horizontal arm that supports a hoist for efficient material handling. Their compact design allows operation in tight spaces while maintaining high load capacity and precise movement. Discover how a jib crane can improve your workflow by reading the rest of this article.

Table of Comparison

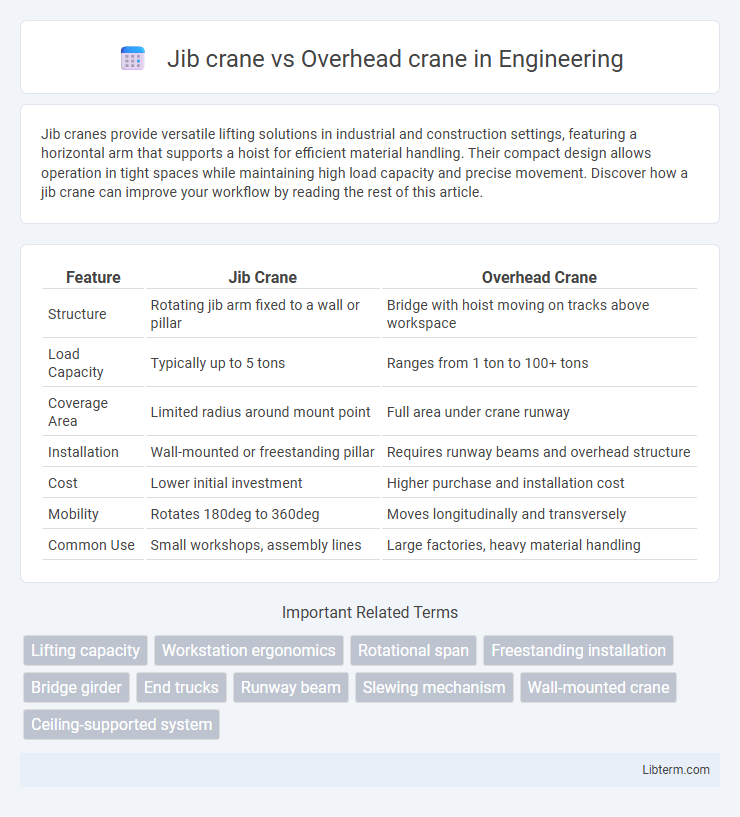

| Feature | Jib Crane | Overhead Crane |

|---|---|---|

| Structure | Rotating jib arm fixed to a wall or pillar | Bridge with hoist moving on tracks above workspace |

| Load Capacity | Typically up to 5 tons | Ranges from 1 ton to 100+ tons |

| Coverage Area | Limited radius around mount point | Full area under crane runway |

| Installation | Wall-mounted or freestanding pillar | Requires runway beams and overhead structure |

| Cost | Lower initial investment | Higher purchase and installation cost |

| Mobility | Rotates 180deg to 360deg | Moves longitudinally and transversely |

| Common Use | Small workshops, assembly lines | Large factories, heavy material handling |

Introduction to Jib Cranes and Overhead Cranes

Jib cranes feature a horizontal arm fixed to a vertical mast, offering localized lifting solutions with a limited radius ideal for small to medium loads. Overhead cranes consist of parallel runways with a hoist trolley, enabling heavy material transport across entire facility spans, suitable for large-scale industrial operations. Both cranes optimize workflow efficiency, with jib cranes providing flexible spot lifting and overhead cranes ensuring comprehensive coverage in manufacturing environments.

Key Differences Between Jib Cranes and Overhead Cranes

Jib cranes feature a swinging arm attached to a vertical mast, providing localized lifting and maneuverability ideal for small to medium work areas. Overhead cranes utilize a horizontal bridge that runs on elevated tracks, enabling lifting and transporting heavy loads across larger factory or warehouse spans. Key differences include load capacity, range of movement, and installation complexity, with jib cranes suited for spot lifting and overhead cranes designed for extensive material handling.

Design and Structure Comparison

Jib cranes feature a horizontal arm (jib) fixed to a vertical mast or wall, allowing rotation and localized lifting within a limited radius, making them ideal for smaller workspaces and precise material handling. Overhead cranes consist of a bridge beam running on elevated rails across a workspace, enabling heavy loads to be moved over longer distances with higher lifting capacity and greater structural complexity. The design of jib cranes prioritizes compact size and flexibility, while overhead cranes emphasize extensive coverage and robust load distribution across industrial environments.

Load Capacity and Lifting Range

Jib cranes typically have a load capacity ranging from 500 kg to 10 tons, making them suitable for localized lifting tasks with a limited radius, usually up to 6 meters. Overhead cranes offer significantly higher load capacities, often exceeding 100 tons, and provide a larger lifting range that spans the entire length and width of a workspace or factory. The selection between jib and overhead cranes depends on the specific load weight and the horizontal coverage required for material handling operations.

Installation and Space Requirements

Jib cranes require minimal space and can be wall-mounted or floor-mounted, allowing flexible installation in smaller or confined areas. Overhead cranes need substantial structural support such as runway beams, demanding more extensive installation space and infrastructure. The compact footprint of jib cranes suits localized lifting tasks, while overhead cranes serve larger workflows across wide industrial spans.

Applications and Industrial Use Cases

Jib cranes are ideal for localized material handling in workshops, manufacturing cells, and loading docks, providing precise lifting for tasks like assembly and maintenance. Overhead cranes excel in heavy-duty industrial environments such as steel plants, shipyards, and warehouses, where they manage large loads over wide areas with high efficiency. Both crane types enhance workflow by improving load movement safety, but jib cranes are suited for limited radius operations while overhead cranes support extensive spatial coverage.

Operation and Maintenance Considerations

Jib cranes offer simpler operation with a limited working radius and fewer moving parts, resulting in lower maintenance requirements compared to overhead cranes. Overhead cranes provide higher load capacities and greater operational flexibility but demand more complex maintenance due to their extensive rail systems and electrical components. Regular inspection, lubrication, and load testing are essential for both crane types to ensure safe and efficient operation.

Cost Analysis: Purchase and Long-Term Value

Jib cranes generally have a lower initial purchase cost compared to overhead cranes, making them a more budget-friendly option for smaller lifting tasks or limited workspace environments. Overhead cranes, while more expensive upfront due to their complex installation and greater load capacity, offer superior long-term value through enhanced durability, increased operational efficiency, and the ability to handle heavier loads. Evaluating total cost of ownership, including maintenance, energy consumption, and productivity gains, often reveals overhead cranes as more cost-effective solutions for large-scale industrial applications.

Safety Features and Compliance

Jib cranes feature a fixed or pivoting arm with a limited radius, incorporating safety components such as overload protection, emergency stop systems, and anti-collision devices designed to prevent accidents during localized lifting operations. Overhead cranes offer comprehensive safety features including hook latches, warning alarms, load limiters, and advanced control systems that ensure compliance with OSHA and ANSI standards for large-scale material handling across industrial environments. Both cranes must adhere to rigorous inspection protocols and regulatory requirements to maintain safe operation and meet industry-specific safety compliance.

Choosing the Right Crane for Your Facility

Selecting between a jib crane and an overhead crane depends on facility layout, load capacity, and operational needs. Jib cranes offer flexible, localized lifting with a fixed or portable base, ideal for repetitive tasks in smaller workspaces. Overhead cranes provide broader coverage and higher weight capacities, suited for large-scale material handling across entire production areas.

Jib crane Infographic

libterm.com

libterm.com