The Howe truss is a popular structural framework commonly used in bridge construction, characterized by its diagonal wooden members slanting towards the center and vertical iron rods providing tension. This design efficiently distributes loads, combining the strengths of timber and metal for enhanced durability and stability. Discover how the Howe truss can improve Your engineering projects by exploring the detailed benefits and applications in the rest of this article.

Table of Comparison

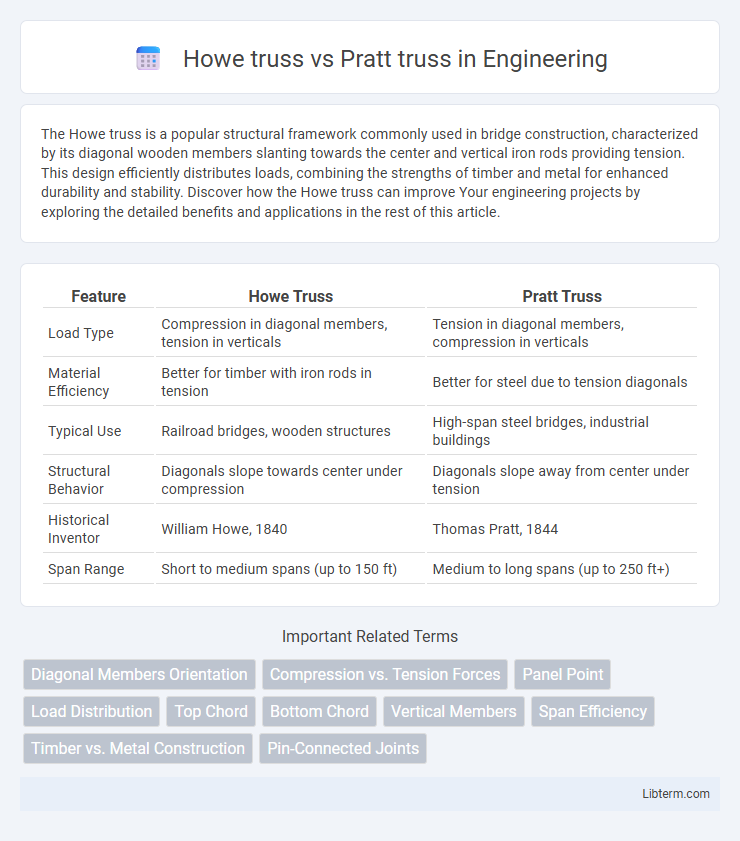

| Feature | Howe Truss | Pratt Truss |

|---|---|---|

| Load Type | Compression in diagonal members, tension in verticals | Tension in diagonal members, compression in verticals |

| Material Efficiency | Better for timber with iron rods in tension | Better for steel due to tension diagonals |

| Typical Use | Railroad bridges, wooden structures | High-span steel bridges, industrial buildings |

| Structural Behavior | Diagonals slope towards center under compression | Diagonals slope away from center under tension |

| Historical Inventor | William Howe, 1840 | Thomas Pratt, 1844 |

| Span Range | Short to medium spans (up to 150 ft) | Medium to long spans (up to 250 ft+) |

Introduction to Howe Truss and Pratt Truss

Howe truss features diagonal members angled towards the center with vertical tension members, making it efficient for handling compression and tension forces in bridge construction. Pratt truss consists of vertical members under compression and diagonal members under tension, optimizing material use for longer spans with lighter loads. Both trusses are critical in structural engineering, with Howe truss preferred for heavy loads and timber construction, while Pratt truss excels in steel frameworks and moderate spans.

Historical Background and Development

The Howe truss, patented by William Howe in 1840, utilizes diagonal wooden members under compression and vertical iron rods under tension, becoming popular in railroad bridges during the 19th century. The Pratt truss, developed by Thomas and Caleb Pratt in 1844, reverses this arrangement by placing diagonal members under tension and vertical members under compression, making it more economical for longer spans and adaptable to steel construction. Both truss designs played pivotal roles in the evolution of bridge engineering, influencing the transition from timber to iron and steel frameworks.

Structural Design Differences

Howe truss features diagonal members that slope towards the center under compression and vertical members under tension, optimizing load distribution for heavy, static loads. Pratt truss reverses this arrangement, with diagonals under tension and verticals under compression, making it more efficient for dynamic or variable loads. The structural design differences influence their applications, with Howe truss favored in timber bridges and Pratt truss commonly used in steel bridges.

Load Distribution Mechanisms

The Howe truss features diagonal members that slope towards the center, placing these diagonals in compression and vertical members in tension, which efficiently distributes loads by transferring weight inward and downward to the supports. In contrast, the Pratt truss has diagonals that slope away from the center, with diagonals primarily in tension and verticals in compression, optimizing load transfer during dynamic loads such as wind or moving vehicles. These differences in load distribution mechanisms impact the structural behavior, making Howe trusses more suitable for heavy, static loads and Pratt trusses better for handling varying or dynamic loads.

Material Usage and Efficiency

Howe truss typically uses timber for compression members and steel for tension members, optimizing material strengths to reduce costs and weight, making it ideal for wooden bridges. Pratt truss employs steel or iron primarily for tension members and wood or steel for compression members, enhancing efficiency in handling dynamic loads and longer spans. The material distribution in both designs maximizes structural efficiency, with Howe truss favoring compression in wood and Pratt truss optimizing tension in steel.

Common Applications in Construction

Howe truss is commonly used in railroad bridges, roof supports, and heavy load-bearing structures due to its diagonal members in compression and vertical members in tension, providing strong support for dynamic loads. Pratt truss is favored in highway bridges, pedestrian bridges, and light to moderate load structures because its diagonal members handle tension while verticals resist compression, optimizing material efficiency and ease of construction. Both truss types are integral in civil engineering projects, with selection based on load type, span length, and construction requirements.

Advantages of Howe Truss

The Howe truss offers superior compressive strength due to its diagonal members being in compression and vertical members in tension, making it ideal for heavy loads and long spans. Its design simplifies construction with fewer tension connections, enhancing durability and reducing maintenance costs. Timber and metal combinations in Howe trusses provide cost-effective solutions for bridges and roof structures, outperforming Pratt trusses in heavy load-bearing applications.

Advantages of Pratt Truss

Pratt truss offers superior efficiency in handling tensile forces, making it ideal for longer spans where tension predominates. Its design involves vertical members under compression and diagonal members under tension, which reduces material usage and enhances structural economy. This configuration simplifies fabrication and maintenance compared to the compression-heavy diagonal members found in Howe trusses, resulting in cost-effective and durable bridge structures.

Limitations and Challenges

Howe trusses face limitations in handling tensile forces due to their wooden diagonal members, which are less effective under tension, making them less suitable for long-span bridges with heavy loads. Pratt trusses encounter challenges in compression as their diagonal members are steel and designed primarily for tension, requiring more maintenance to prevent buckling under load. Both truss types demand careful material selection and engineering analysis to address these structural vulnerabilities and optimize performance.

Comparative Summary: Choosing the Right Truss

Howe truss features diagonal members in compression and vertical members in tension, making it ideal for heavy loads and timber construction, while Pratt truss has diagonal members in tension and vertical members in compression, offering better efficiency with steel materials. The choice between Howe and Pratt trusses depends on factors such as material type, span length, and load distribution requirements, with Howe preferred for wooden bridges and Pratt favored for longer steel bridges. Understanding load paths and structural behavior ensures optimal performance and cost-effectiveness in bridge design.

Howe truss Infographic

libterm.com

libterm.com