Baltimore truss is a type of steel truss bridge design characterized by its subdivided panels and diagonal bracing, providing enhanced strength and load distribution for heavy loads and long spans. This structural system is commonly used in railroad bridges and highway overpasses, offering durability and efficient use of materials. Discover how the Baltimore truss can impact your next engineering project by reading the full article.

Table of Comparison

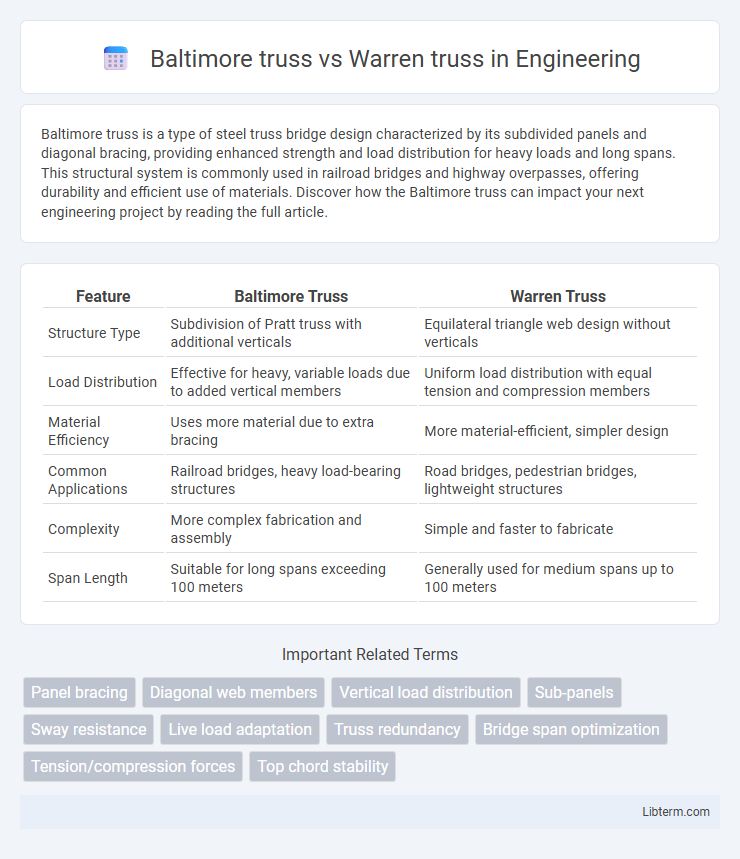

| Feature | Baltimore Truss | Warren Truss |

|---|---|---|

| Structure Type | Subdivision of Pratt truss with additional verticals | Equilateral triangle web design without verticals |

| Load Distribution | Effective for heavy, variable loads due to added vertical members | Uniform load distribution with equal tension and compression members |

| Material Efficiency | Uses more material due to extra bracing | More material-efficient, simpler design |

| Common Applications | Railroad bridges, heavy load-bearing structures | Road bridges, pedestrian bridges, lightweight structures |

| Complexity | More complex fabrication and assembly | Simple and faster to fabricate |

| Span Length | Suitable for long spans exceeding 100 meters | Generally used for medium spans up to 100 meters |

Introduction to Baltimore and Warren Trusses

Baltimore trusses feature a complex design with additional verticals and sub-diagonals, enhancing load distribution and making them ideal for heavy railroad bridges. Warren trusses use equilateral triangles formed by alternating diagonal members, providing efficient material use and even load transfer in lighter to moderate span applications. Both truss types are fundamental in structural engineering, with Baltimore trusses favored for heavy-duty performance and Warren trusses known for simplicity and economical construction.

Historical Background of Truss Designs

The Baltimore truss, developed in the late 19th century, evolved as an enhancement of the Pratt truss, incorporating additional bracing to support heavier loads on railroad bridges during the industrial expansion of the United States. The Warren truss, patented by James Warren and Willoughby Monzani in 1848, features equilateral triangles that provide a uniform distribution of tension and compression forces, making it popular for its simplicity and efficient use of materials in early steel bridge construction. Both designs significantly influenced bridge engineering, with the Baltimore truss favored for long-span rail applications and the Warren truss widely adopted for roadway bridges due to its ease of fabrication and structural efficiency.

Structural Design: Baltimore vs Warren Truss

Baltimore truss features a subdivided design with additional vertical and diagonal members, enhancing load distribution and allowing it to support heavier loads over longer spans. Warren truss utilizes a simpler triangular framework with alternating diagonal members, optimizing material efficiency and reducing weight while maintaining structural integrity. The choice between Baltimore and Warren trusses depends on load requirements, span length, and material constraints, with Baltimore truss generally preferred for heavier, longer bridges and Warren truss favored for lighter, shorter spans.

Key Features and Components

Baltimore truss features subdivided panels with additional verticals and diagonals, enhancing load distribution and strength, ideal for heavy railway and vehicular bridges. Warren truss uses equilateral triangles with no vertical members, providing efficient material use and uniform force distribution, suitable for medium spans and lighter loads. Key components of Baltimore truss include multiple verticals and sub-struts, while Warren truss relies on alternating diagonal members forming repetitive triangular patterns.

Load Distribution and Efficiency

The Baltimore truss features additional vertical and diagonal members that enhance load distribution by reducing the length of compression members, making it highly efficient for heavier loads and longer spans. In contrast, the Warren truss uses equilateral triangles with fewer members, providing efficient load transfer through axial forces but less redundancy under concentrated loads. Baltimore trusses excel in structures requiring increased rigidity and load capacity, while Warren trusses prioritize material economy and simplicity for moderate load conditions.

Material Usage and Construction Methods

Baltimore trusses utilize additional vertical and diagonal members within each panel, increasing material usage compared to the simpler Warren truss, which employs equilateral triangles with fewer members, reducing steel consumption. Construction of Baltimore trusses often requires more complex fabrication and assembly processes due to the increased number of components and connections, while Warren trusses benefit from straightforward, repetitive connections that streamline fabrication and reduce labor costs. The choice between these truss types depends on balancing structural requirements with material efficiency and construction complexity for specific project demands.

Applications in Modern Engineering

Baltimore truss bridges are commonly applied in heavy-load railway and large-scale highway projects due to their additional verticals and subdivided panels, which enhance load distribution and structural stability. Warren truss designs, characterized by equilateral triangles and fewer members, are favored for pedestrian bridges, short- to medium-span roadways, and lightweight industrial structures because of their efficient material usage and ease of fabrication. Modern engineering leverages Baltimore trusses for high-stress environments requiring increased durability, while Warren trusses excel in cost-effective, moderate-load applications where simplicity and speed of construction are critical.

Advantages of Baltimore Truss

Baltimore truss offers enhanced structural strength and load distribution due to its additional vertical and diagonal members, making it ideal for longer spans and heavier loads compared to the Warren truss. Its subdivided panels reduce the length of compression members, minimizing buckling risks and increasing overall stability and durability. This truss design also excels in resisting dynamic loads, which is beneficial for railway and highway bridges frequently subjected to varying stresses.

Advantages of Warren Truss

The Warren truss offers a more efficient distribution of loads due to its equilateral triangle design, which minimizes bending moments and reduces material stress. This design allows for lighter construction and cost savings while maintaining structural integrity. Compared to the Baltimore truss, the Warren truss requires less maintenance and is easier to fabricate and assemble.

Comparison Summary: Which Truss to Choose?

Baltimore truss offers enhanced load distribution with its subdivided panels, making it ideal for heavy railway and highway bridges requiring high strength and stiffness. Warren truss features a simpler, triangular pattern that provides efficient load transfer and ease of fabrication, suitable for shorter spans and lighter loads. Choose Baltimore truss for heavy-duty, longer-span applications demanding durability, while Warren truss suits economical designs with moderate load requirements.

Baltimore truss Infographic

libterm.com

libterm.com