Peristaltic pumps provide precise, contamination-free fluid transfer by using a rotating mechanism to compress flexible tubing, ensuring gentle and accurate flow. These pumps are ideal for handling sensitive or abrasive fluids in medical, chemical, and food industries due to their self-priming and clean operation. Discover how peristaltic pumps can enhance your fluid management by exploring the detailed benefits and applications in this article.

Table of Comparison

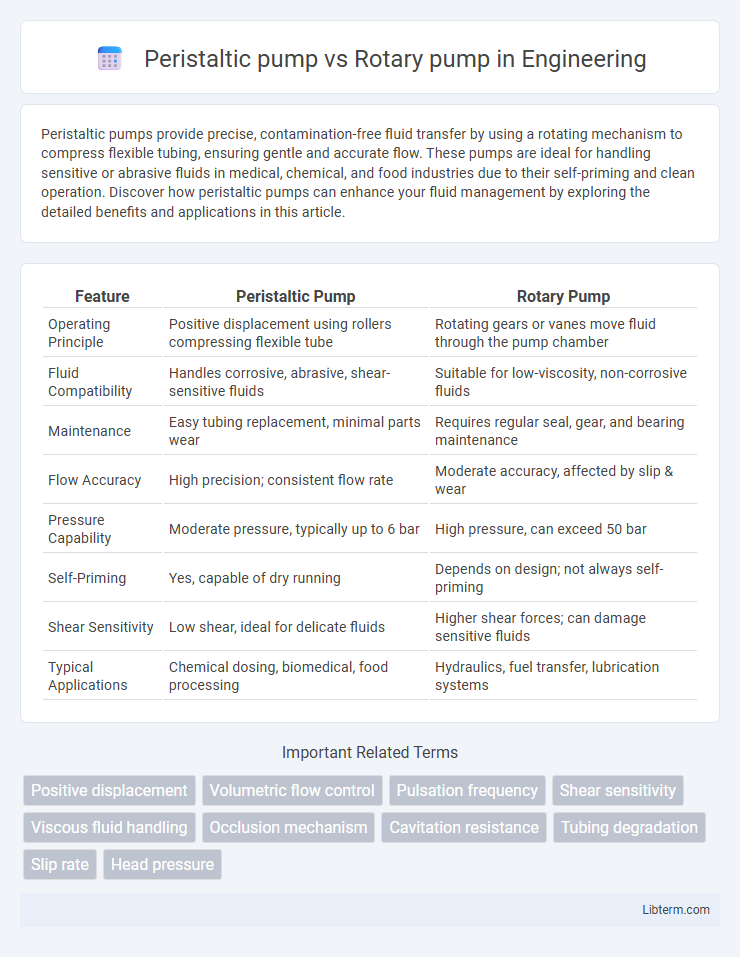

| Feature | Peristaltic Pump | Rotary Pump |

|---|---|---|

| Operating Principle | Positive displacement using rollers compressing flexible tube | Rotating gears or vanes move fluid through the pump chamber |

| Fluid Compatibility | Handles corrosive, abrasive, shear-sensitive fluids | Suitable for low-viscosity, non-corrosive fluids |

| Maintenance | Easy tubing replacement, minimal parts wear | Requires regular seal, gear, and bearing maintenance |

| Flow Accuracy | High precision; consistent flow rate | Moderate accuracy, affected by slip & wear |

| Pressure Capability | Moderate pressure, typically up to 6 bar | High pressure, can exceed 50 bar |

| Self-Priming | Yes, capable of dry running | Depends on design; not always self-priming |

| Shear Sensitivity | Low shear, ideal for delicate fluids | Higher shear forces; can damage sensitive fluids |

| Typical Applications | Chemical dosing, biomedical, food processing | Hydraulics, fuel transfer, lubrication systems |

Introduction to Peristaltic and Rotary Pumps

Peristaltic pumps operate by compressing and releasing a flexible tube to move fluid, providing precise, contamination-free transfer ideal for abrasive or sterile fluids. Rotary pumps use rotating gears, lobes, or vanes to create a vacuum and move fluid, offering consistent flow rates and high pressure suitable for viscous liquids. Both pump types serve diverse industrial applications, with peristaltic pumps excelling in gentle, clean pumping and rotary pumps preferred for high-efficiency fluid transfer.

Overview of Peristaltic Pump Technology

Peristaltic pump technology uses a series of rollers or shoes to compress a flexible tube, creating a controlled, pulseless flow ideal for precise dosing and sanitary fluid handling. Its design eliminates contact between the pump mechanism and the fluid, reducing contamination risk and enabling safe transfer of aggressive, abrasive, or sterile liquids. Unlike rotary pumps, peristaltic pumps provide gentle pumping action with easy maintenance due to minimal moving parts and simple tube replacements.

Overview of Rotary Pump Technology

Rotary pumps operate by trapping fluid between rotating components and the pump casing, enabling continuous flow with minimal pulsation. They are preferred for applications requiring precise flow control and high pressure, handling viscous fluids efficiently. Common types include gear, lobe, and vane pumps, each offering distinct advantages in durability and maintenance.

Key Differences Between Peristaltic and Rotary Pumps

Peristaltic pumps use a rotating roller to compress a flexible tube, creating a pulsatile flow ideal for hygienic and precise fluid transfer, whereas rotary pumps employ meshing gears or vanes to provide continuous, steady flow suitable for high-pressure applications. Peristaltic pumps excel in handling abrasive, shear-sensitive, and sterile fluids without contamination risk due to tubing isolation, while rotary pumps are better for consistent, high-viscosity liquids but may require seals prone to leakage. Maintenance demands differ, with peristaltic pumps needing regular tubing replacement and rotary pumps requiring seal and gear lubrication checks.

Fluid Compatibility and Chemical Handling

Peristaltic pumps excel in fluid compatibility due to their tube-based design, which isolates the fluid from pump components, making them ideal for handling aggressive chemicals, abrasive slurries, and shear-sensitive fluids without contamination. Rotary pumps, while efficient for viscous fluids, often have direct fluid contact with internal components, potentially causing compatibility issues with corrosive substances and requiring specific materials like stainless steel or specialized coatings. For chemical handling applications demanding high purity and resistance to corrosion, peristaltic pumps offer superior chemical resistance and reduced maintenance risks.

Maintenance and Operational Costs

Peristaltic pumps require minimal maintenance due to their simple design with no seals or valves, reducing downtime and servicing expenses. Rotary pumps, however, involve higher operational costs because of regular seal replacements and more frequent wear on internal components. Overall, peristaltic pumps offer lower maintenance and operational costs, making them ideal for applications with abrasive or corrosive fluids.

Flow Accuracy and Consistency

Peristaltic pumps provide superior flow accuracy and consistency by using a tubing compression mechanism that ensures precise, pulse-free fluid delivery with minimal risk of contamination. Rotary pumps achieve flow by trapping and moving fluid through rotating gears or vanes, which can introduce pulsation and variability affecting accuracy. For applications demanding high precision and sterile conditions, peristaltic pumps offer distinct advantages over rotary pumps in maintaining consistent, controllable flow rates.

Applications and Industry Use Cases

Peristaltic pumps excel in pharmaceutical, food processing, and chemical industries due to their hygienic design and ability to handle abrasive, sterile, or corrosive fluids without contamination. Rotary pumps find extensive use in oil and gas, automotive, and manufacturing sectors for transferring viscous fluids, lubricants, and fuels with high efficiency and consistent flow rates. Both pump types are integral in water treatment, with peristaltic pumps preferred for precise dosing and rotary pumps favored for high-volume fluid transfer.

Energy Efficiency and Performance

Peristaltic pumps exhibit high energy efficiency due to minimal internal friction and the ability to handle viscous fluids with low power consumption, making them ideal for precise dosing and gentle fluid transfer. Rotary pumps, while generally offering higher flow rates and pressure capabilities, may consume more energy due to mechanical components and slippage, which can reduce overall efficiency in certain applications. Performance in terms of maintenance favors peristaltic pumps, as they have fewer moving parts contacting the fluid, reducing wear and enhancing long-term operational reliability.

Choosing the Right Pump for Your Needs

Peristaltic pumps excel in handling abrasive, shear-sensitive, and sterile fluids due to their gentle, tubing-driven mechanism, making them ideal for medical, pharmaceutical, and food applications. Rotary pumps provide consistent high pressure and flow rates, fitting well in industries like oil, fuel transfer, and hydraulic systems where robust pumping of viscous fluids is needed. Choosing between these pumps depends on fluid properties, required flow accuracy, and maintenance preferences to ensure optimal performance and longevity.

Peristaltic pump Infographic

libterm.com

libterm.com