Understanding fluid mechanics is essential for analyzing the behavior of liquids and gases in various applications, from engineering to natural phenomena. This field explores key concepts such as fluid flow, pressure, viscosity, and turbulence to predict how fluids interact with their environments. Discover deeper insights into fluid mechanics to enhance your knowledge and apply it effectively by reading the full article.

Table of Comparison

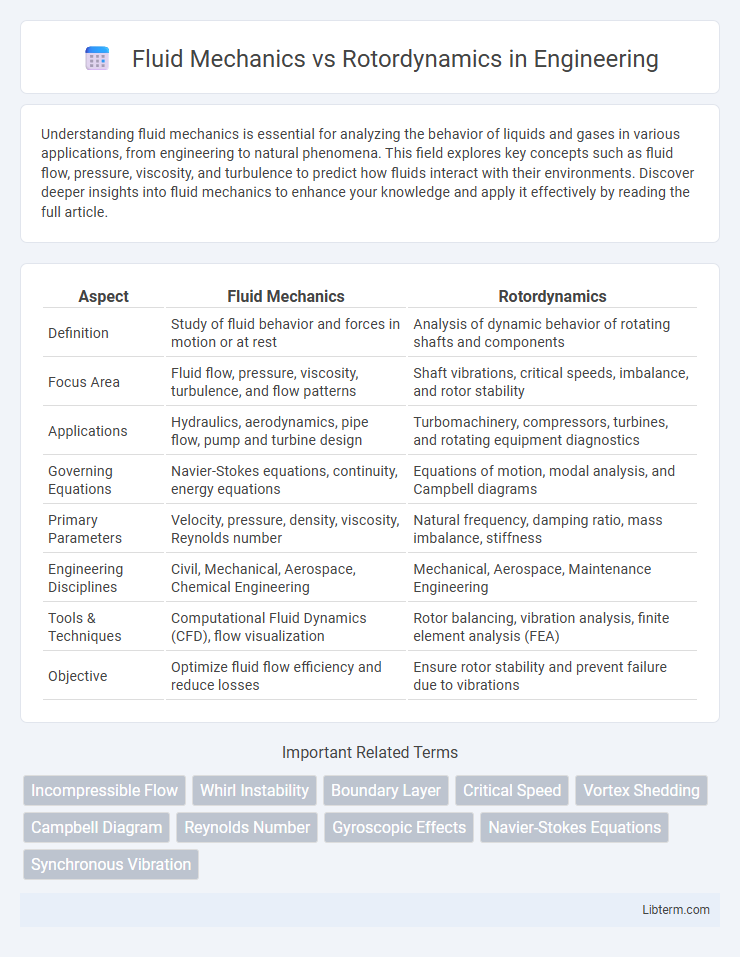

| Aspect | Fluid Mechanics | Rotordynamics |

|---|---|---|

| Definition | Study of fluid behavior and forces in motion or at rest | Analysis of dynamic behavior of rotating shafts and components |

| Focus Area | Fluid flow, pressure, viscosity, turbulence, and flow patterns | Shaft vibrations, critical speeds, imbalance, and rotor stability |

| Applications | Hydraulics, aerodynamics, pipe flow, pump and turbine design | Turbomachinery, compressors, turbines, and rotating equipment diagnostics |

| Governing Equations | Navier-Stokes equations, continuity, energy equations | Equations of motion, modal analysis, and Campbell diagrams |

| Primary Parameters | Velocity, pressure, density, viscosity, Reynolds number | Natural frequency, damping ratio, mass imbalance, stiffness |

| Engineering Disciplines | Civil, Mechanical, Aerospace, Chemical Engineering | Mechanical, Aerospace, Maintenance Engineering |

| Tools & Techniques | Computational Fluid Dynamics (CFD), flow visualization | Rotor balancing, vibration analysis, finite element analysis (FEA) |

| Objective | Optimize fluid flow efficiency and reduce losses | Ensure rotor stability and prevent failure due to vibrations |

Introduction to Fluid Mechanics and Rotordynamics

Fluid Mechanics explores the behavior of fluids in motion and at rest, addressing key principles such as viscosity, pressure, and flow dynamics critical for engineering applications. Rotordynamics examines the dynamic behavior of rotating machinery components, focusing on vibration analysis, stability, and critical speeds to prevent failures in turbines, compressors, and motors. Understanding Fluid Mechanics provides foundational insights into fluid forces affecting rotor systems, while Rotordynamics applies these concepts to analyze and optimize rotating equipment performance.

Fundamental Concepts in Fluid Mechanics

Fluid mechanics centers on the study of fluid behavior, encompassing the principles of fluid statics, fluid kinematics, and fluid dynamics, which describe pressure distribution, flow velocity, and forces within fluids. Key concepts include the continuity equation, Bernoulli's principle, and Navier-Stokes equations that govern laminar and turbulent flow regimes. In contrast, rotordynamics applies these principles to rotating systems, focusing on vibration, stability, and fluid-induced forces affecting rotors in machinery.

Core Principles of Rotordynamics

Rotordynamics centers on the analysis of rotating machinery through the study of vibration and stability in rotating shafts, emphasizing critical speeds, unbalance responses, and bearing dynamics. Unlike fluid mechanics, which primarily investigates fluid flow behavior and forces, rotordynamics integrates concepts from structural dynamics and fluid-induced forces to predict rotor behavior under operational conditions. Core principles entail analyzing gyroscopic effects, damping mechanisms, and stiffness variations to ensure optimal rotor performance and prevent mechanical failures.

Key Differences Between Fluid Mechanics and Rotordynamics

Fluid mechanics studies the behavior, motion, and forces of fluids (liquids and gases) under various conditions, emphasizing flow dynamics, turbulence, and pressure distribution. Rotordynamics focuses specifically on the dynamic behavior of rotating shafts and their interactions with supports, including vibration analysis, stability, and rotor-bearing system performance. Key differences lie in fluid mechanics addressing fluid flow and properties, while rotordynamics centers on the mechanical dynamics of rotating machinery components.

Mathematical Models in Fluid Mechanics vs Rotordynamics

Mathematical models in fluid mechanics primarily involve the Navier-Stokes equations, describing the motion of fluid substances through velocity, pressure, density, and viscosity fields. In contrast, rotordynamics focuses on the dynamic behavior of rotating shafts and their support systems, using equations of motion formulated through rigid body dynamics coupled with elasticity and damping effects. Both fields employ differential equations but differ in application scope, with fluid mechanics addressing fluid flow phenomena and rotordynamics modeling vibration, stability, and critical speeds of rotating machinery.

Applications of Fluid Mechanics

Fluid mechanics is crucial in designing hydraulic systems, predicting weather patterns, and optimizing aerodynamic performance in aerospace engineering. It enables the analysis of fluid flow in pipelines, pumps, and turbines, ensuring efficient energy transfer and system stability. These applications highlight fluid mechanics' role in improving industrial processes and environmental management compared to rotordynamics, which focuses primarily on the dynamic behavior of rotating machinery.

Industrial Relevance of Rotordynamics

Rotordynamics plays a critical role in industrial applications by analyzing the dynamic behavior of rotating machinery such as turbines, compressors, and pumps to prevent failures and optimize performance. Its relevance extends to predictive maintenance, vibration analysis, and fault diagnosis, ensuring reliability and minimizing downtime in sectors like power generation, aerospace, and manufacturing. While fluid mechanics governs the behavior of fluids within these machines, rotordynamics specifically addresses the mechanical stability and resonance phenomena of rotating components, making it indispensable for safe and efficient industrial operation.

Challenges in Fluid Mechanics Studies

Fluid Mechanics studies face challenges in accurately modeling turbulent flow behavior and predicting complex fluid-structure interactions, which require advanced computational methods and experimental validation. High Reynolds number flows and multiphase systems introduce nonlinear dynamics that complicate analytical solutions and numerical stability. Precise measurement of velocity fields and pressure distributions in real-world applications remains difficult, impacting the reliability of simulation data for engineering designs.

Common Issues in Rotordynamics Analysis

Common issues in rotordynamics analysis often stem from fluid-structure interactions, such as turbulence-induced vibrations and fluid film bearing instabilities. Misalignment, unbalance, and shaft whip are amplified by inadequate consideration of the fluid forces acting on rotating components. Precise modeling of hydrodynamic effects and damping characteristics enhances the accuracy of predicting critical speeds and avoiding resonance conditions in rotating machinery.

Future Trends: Integrating Fluid Mechanics and Rotordynamics

Future trends in fluid mechanics and rotordynamics emphasize the integration of advanced computational fluid dynamics (CFD) with rotordynamic simulations to enhance predictive accuracy of rotor behavior under complex fluid-structure interactions. Emerging technologies leverage machine learning algorithms to optimize rotor design and minimize vibration and instability in aerospace and energy systems. This integrated approach aims to improve performance, safety, and efficiency in high-speed rotating machinery by addressing challenges such as fluid-induced instabilities and thermal effects.

Fluid Mechanics Infographic

libterm.com

libterm.com