Stress relaxation refers to the gradual decrease in stress experienced by a material or tissue under constant strain over time. This phenomenon is crucial in industries such as manufacturing and biomechanics, where understanding material behavior under prolonged load can prevent failure and improve design efficiency. Explore the rest of the article to learn how stress relaxation impacts your projects and how to manage it effectively.

Table of Comparison

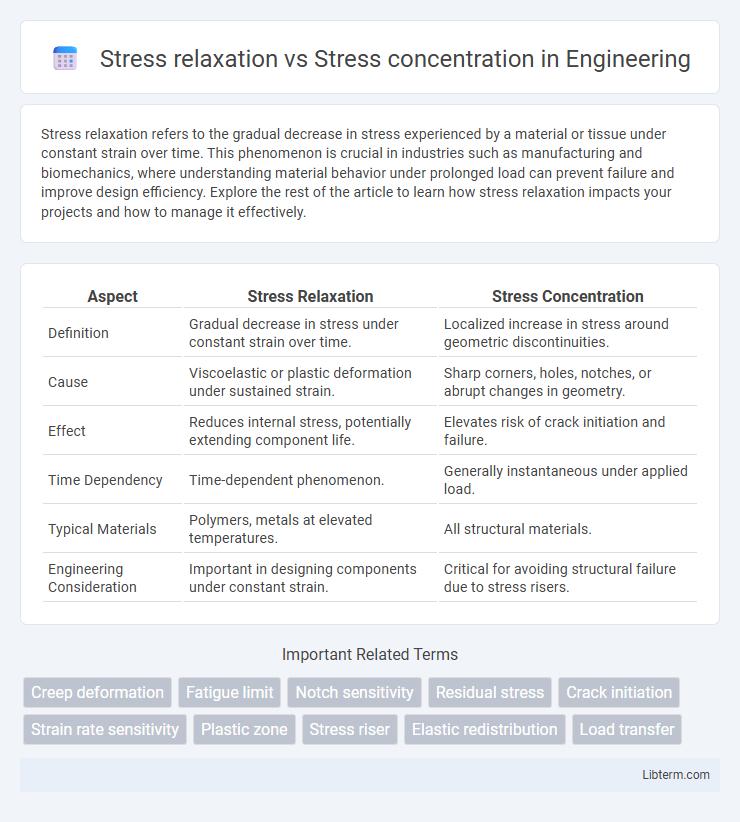

| Aspect | Stress Relaxation | Stress Concentration |

|---|---|---|

| Definition | Gradual decrease in stress under constant strain over time. | Localized increase in stress around geometric discontinuities. |

| Cause | Viscoelastic or plastic deformation under sustained strain. | Sharp corners, holes, notches, or abrupt changes in geometry. |

| Effect | Reduces internal stress, potentially extending component life. | Elevates risk of crack initiation and failure. |

| Time Dependency | Time-dependent phenomenon. | Generally instantaneous under applied load. |

| Typical Materials | Polymers, metals at elevated temperatures. | All structural materials. |

| Engineering Consideration | Important in designing components under constant strain. | Critical for avoiding structural failure due to stress risers. |

Understanding Stress Relaxation and Stress Concentration

Stress relaxation refers to the gradual decrease in stress in a material subjected to constant strain over time, commonly observed in polymers and metals under high temperature or prolonged loading conditions. Stress concentration occurs at specific points such as notches, holes, or sharp corners where stress intensity is significantly higher than the average stress, leading to potential failure initiation. Understanding stress relaxation helps in predicting material lifespan under sustained loads, while recognizing stress concentration is crucial for design optimization to prevent structural failure.

Defining Stress Relaxation: Key Concepts

Stress relaxation refers to the gradual decrease in stress experienced by a material held under constant strain over time, commonly observed in polymers and metals at elevated temperatures. This phenomenon occurs due to molecular rearrangements or dislocation movements that reduce internal stresses, enhancing the material's ability to maintain its shape under prolonged load. Stress concentration, by contrast, relates to localized increases in stress around notches, holes, or abrupt changes in geometry, which do not diminish over time but can significantly affect material strength and fatigue life.

What is Stress Concentration? An Overview

Stress concentration refers to the localized increase in stress around discontinuities such as holes, notches, or cracks within a material, where stress can exceed the average stress by several times. It plays a critical role in material failure and fatigue, as these high-stress regions become initiation sites for cracks and fractures. Understanding stress concentration factors (SCFs) is essential for designing components that can withstand mechanical loads without premature failure.

Causes of Stress Relaxation in Materials

Stress relaxation in materials occurs due to molecular or atomic rearrangements under prolonged stress, often influenced by factors such as temperature, time, and material composition. Causes of stress relaxation include creep deformation, dislocation movement, and viscoelastic behavior, leading to a gradual decrease in internal stress without external load changes. In contrast, stress concentration arises from geometric discontinuities like notches or sharp corners, causing localized increases in stress rather than uniform stress decay.

Factors Leading to Stress Concentrations

Stress concentration occurs when stress is amplified in localized areas due to geometric discontinuities such as holes, notches, sharp corners, or sudden changes in cross-section, which disrupt uniform stress distribution. Material defects like cracks, inclusions, and surface roughness also contribute significantly to stress concentrations by creating points where stress can accumulate. These factors increase the likelihood of failure by causing localized plastic deformation or crack initiation under load.

Effects of Stress Relaxation on Material Performance

Stress relaxation reduces internal stresses in materials subjected to constant strain over time, improving long-term performance by minimizing the risk of crack initiation and structural failure. This phenomenon is critical in polymers, metals, and composites where maintaining dimensional stability and load-bearing capacity is essential. In contrast to stress concentration, which localizes stress and promotes damage, stress relaxation helps distribute stresses more evenly and enhances material durability under cyclic or sustained loading conditions.

Impact of Stress Concentration on Structural Integrity

Stress concentration significantly affects structural integrity by causing localized increases in stress around notches, holes, or abrupt changes in geometry, leading to premature material failure. These stress risers can initiate cracks that propagate rapidly under cyclic loading, reducing the lifespan of components. Unlike stress relaxation, which decreases internal stress over time, stress concentration intensifies stress, making targeted design modifications and material selection critical to ensuring durability and safety.

Techniques to Measure Stress Relaxation and Concentration

Stress relaxation is commonly measured using techniques like creep testing, where the material is subjected to constant strain and the decay in stress is recorded over time, and stress relaxation testing, which involves maintaining a constant strain and monitoring the decrease in stress. Stress concentration is typically evaluated through methods such as photoelasticity, digital image correlation (DIC), and finite element analysis (FEA), which help visualize and quantify localized stress intensifications around geometric discontinuities. Accurate measurement of both stress relaxation and concentration is critical for predicting material performance and preventing failure in engineering applications.

Engineering Strategies for Minimizing Stress Concentration

Stress relaxation reduces internal stresses over time through material deformation, while stress concentration refers to localized stress intensification around geometric discontinuities such as notches or holes. Engineering strategies for minimizing stress concentration include optimizing component geometry by increasing fillet radii, employing smooth transitions in cross-sectional areas, and using composite materials to distribute stress more evenly. Finite element analysis (FEA) aids in identifying critical stress concentration points and guiding design modifications to enhance durability and prevent structural failure.

Comparing Stress Relaxation vs Stress Concentration in Industrial Applications

Stress relaxation refers to the gradual decrease in stress under a constant strain over time, commonly observed in materials subjected to prolonged loading, which affects the long-term stability of components like seals and gaskets. Stress concentration, on the other hand, occurs at geometric discontinuities such as notches or holes, leading to localized high stress that can cause premature failure in structures like beams and pressure vessels. Comparing stress relaxation and stress concentration in industrial applications highlights the importance of material selection and design optimization to mitigate long-term deformation and prevent sudden catastrophic failures.

Stress relaxation Infographic

libterm.com

libterm.com