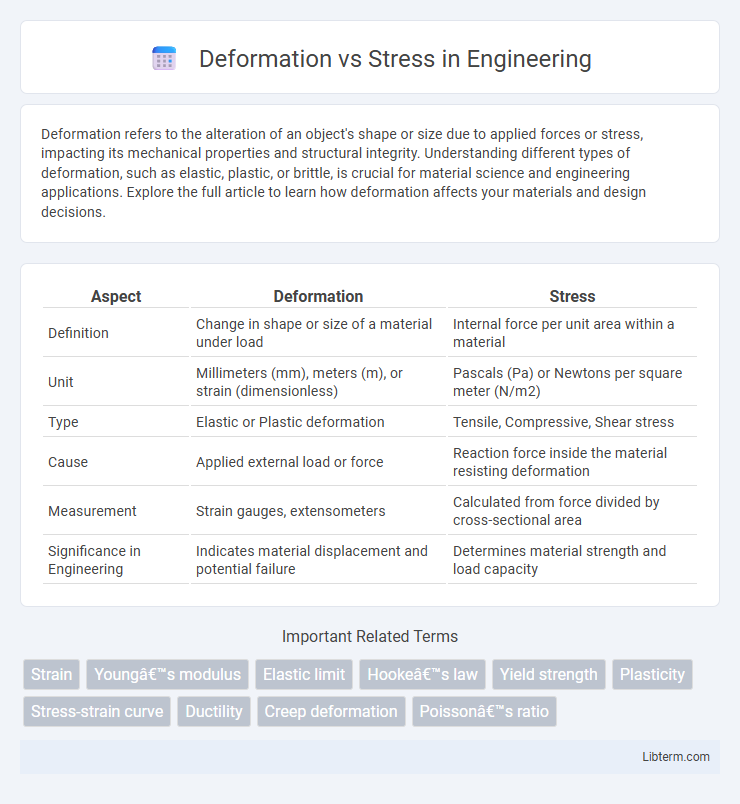

Deformation refers to the alteration of an object's shape or size due to applied forces or stress, impacting its mechanical properties and structural integrity. Understanding different types of deformation, such as elastic, plastic, or brittle, is crucial for material science and engineering applications. Explore the full article to learn how deformation affects your materials and design decisions.

Table of Comparison

| Aspect | Deformation | Stress |

|---|---|---|

| Definition | Change in shape or size of a material under load | Internal force per unit area within a material |

| Unit | Millimeters (mm), meters (m), or strain (dimensionless) | Pascals (Pa) or Newtons per square meter (N/m2) |

| Type | Elastic or Plastic deformation | Tensile, Compressive, Shear stress |

| Cause | Applied external load or force | Reaction force inside the material resisting deformation |

| Measurement | Strain gauges, extensometers | Calculated from force divided by cross-sectional area |

| Significance in Engineering | Indicates material displacement and potential failure | Determines material strength and load capacity |

Understanding Deformation and Stress

Deformation refers to the change in shape or size of a material when subjected to external forces, while stress quantifies the internal force per unit area within the material resisting that deformation. Understanding the relationship between deformation and stress is crucial for predicting material behavior under load and designing structures to withstand applied forces. Accurate measurement of strain, which describes deformation, and calculation of stress enable engineers to evaluate material performance and ensure safety in mechanical and civil applications.

Definition of Deformation

Deformation refers to the change in shape or size of a material subjected to an external force, stress, or load, causing displacement of particles within the material. It is quantified by strain, representing the relative displacement between particles in the material body. Unlike stress, which measures internal forces per unit area, deformation directly describes the physical distortion experienced by the material.

Definition of Stress

Stress is defined as the internal force per unit area within a material that arises in response to external loads, causing deformation. It quantifies how much force is distributed over a specific cross-sectional area, measured in pascals (Pa). Understanding stress is essential for predicting material behavior and preventing failure in engineering applications.

Types of Deformation

Deformation in materials occurs primarily as elastic, plastic, and brittle types, each corresponding to different stress responses. Elastic deformation is reversible and occurs under low stress, where the material returns to its original shape once the load is removed. Plastic deformation involves permanent shape change after exceeding the yield stress, while brittle deformation results in fracture without significant prior deformation.

Types of Stress

Types of stress in materials include tensile stress, which stretches the material; compressive stress, which squeezes it; and shear stress, which causes layers to slide relative to each other. Each type of stress produces specific deformation patterns that affect the material's structural integrity and mechanical properties. Understanding the relationship between these stress types and resulting deformation is critical for designing materials that withstand operational forces.

Key Differences Between Deformation and Stress

Deformation refers to the change in shape or size of a material when subjected to external forces, measured as strain, whereas stress is the internal force per unit area within a material resisting deformation, expressed in pascals (Pa). Stress quantifies the intensity of the internal forces, while deformation represents the actual physical displacement or distortion occurring in the material. Understanding the distinction between stress as a cause and deformation as an effect is fundamental in material science and structural engineering.

Causes of Deformation in Materials

Deformation in materials occurs primarily due to applied stress exceeding the material's elastic limit, causing atomic bonds to stretch, slide, or break. External forces such as tension, compression, shear, or torsion generate internal stresses that disrupt the material's structural integrity. Temperature changes and material defects like dislocations or impurities also contribute to the initiation and progression of deformation.

Effects of Stress on Material Properties

Stress impacts material properties by altering their mechanical behavior, including changes in elasticity, plasticity, and strength. High stress levels can cause permanent deformation, microstructural damage, and reduced fatigue life, leading to eventual material failure. Understanding the stress-strain relationship is essential for predicting material performance under various loading conditions.

Real-world Examples of Deformation and Stress

Deformation and stress are critical in understanding material behavior under load; for example, bridges experience tensile stress causing elongation of steel cables, while earthquakes induce stress leading to concrete deformation in buildings. Aircraft wings undergo cyclic stress during flight, resulting in elastic deformation that can be monitored to prevent structural failure. In everyday objects like rubber bands, applied stress causes significant elastic deformation visible as stretching, illustrating material response under mechanical load.

Importance of Studying Deformation and Stress in Engineering

Understanding deformation and stress is crucial in engineering to ensure the structural integrity and safety of materials under various load conditions. Analyzing stress helps predict potential failure points, while studying deformation reveals how materials change shape or size, informing design improvements. Optimizing these factors improves durability, performance, and cost-efficiency in engineering projects.

Deformation Infographic

libterm.com

libterm.com