The addendum circle is a crucial concept in gear design, representing the outermost boundary of a gear tooth where the addendum, or the tooth height above the pitch circle, terminates. This circle defines the maximum radius of the gear and plays a significant role in ensuring proper meshing and avoiding interference between mating gears. Explore the rest of the article to understand how the addendum circle affects gear performance and precision.

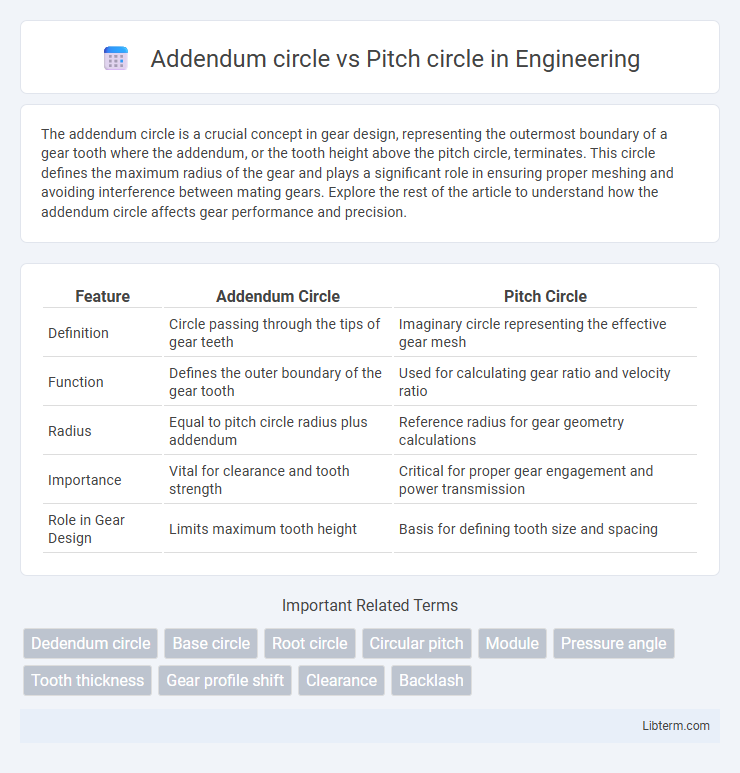

Table of Comparison

| Feature | Addendum Circle | Pitch Circle |

|---|---|---|

| Definition | Circle passing through the tips of gear teeth | Imaginary circle representing the effective gear mesh |

| Function | Defines the outer boundary of the gear tooth | Used for calculating gear ratio and velocity ratio |

| Radius | Equal to pitch circle radius plus addendum | Reference radius for gear geometry calculations |

| Importance | Vital for clearance and tooth strength | Critical for proper gear engagement and power transmission |

| Role in Gear Design | Limits maximum tooth height | Basis for defining tooth size and spacing |

Introduction to Addendum Circle and Pitch Circle

The addendum circle represents the outermost boundary of gear teeth, defined by the tips of the teeth, while the pitch circle is an imaginary circle that passes through the gear tooth profiles where mating gears theoretically engage without slipping. The pitch circle diameter (PCD) is crucial for gear design, affecting the gear ratio and velocity ratio, whereas the addendum circle diameter includes the addendum length, influencing the overall gear size. Understanding the distinction between the pitch circle and addendum circle is fundamental for accurate gear mesh and performance optimization.

Definitions: Addendum Circle vs Pitch Circle

The Addendum Circle is the outermost circle of a gear tooth, representing the tip of the gear teeth, while the Pitch Circle is an imaginary circle that defines the gear's effective diameter where teeth theoretically engage with a mating gear. The Pitch Circle is crucial for calculating gear ratios and is used to determine the gear's size and speed relationship, whereas the Addendum Circle helps define the gear tooth height above the Pitch Circle. Understanding the distinctions between the Addendum Circle and Pitch Circle is essential for precise gear design and ensuring proper meshing and performance.

Geometric Relationships Between the Circles

Addendum circle represents the outer boundary of gear teeth, while the pitch circle is the theoretical circle where gears effectively engage. The addendum circle's diameter exceeds the pitch circle diameter by twice the addendum value, establishing a precise geometric relationship. This difference directly influences gear meshing, clearance, and overall transmission efficiency in mechanical systems.

Role in Gear Design and Function

The addendum circle defines the outermost boundary of a gear tooth, directly influencing the gear's capability to engage and transmit torque without interference. The pitch circle serves as the fundamental reference for gear geometry, determining the effective diameter where gears mesh smoothly and maintain consistent velocity ratio. Precise differentiation between the addendum and pitch circles ensures optimal gear tooth strength, accurate load distribution, and efficient power transmission in gear design.

Calculation Methods for Each Circle

Addendum circle calculation involves adding the addendum length to the pitch circle radius, which defines the outermost boundary of the gear tooth. Pitch circle radius is derived from the gear module and the number of teeth, serving as the fundamental reference for gear geometry and meshing calculations. Accurate determination of both circles ensures proper tooth engagement and optimal gear performance.

Impact on Gear Tooth Profile

The addendum circle and pitch circle play crucial roles in defining the gear tooth profile, where the addendum circle marks the outermost boundary of the gear teeth and impacts tooth height and clearance. The pitch circle, representing the theoretical rolling contact line between meshing gears, influences the effective diameter for calculating gear ratios and velocity. Variations in the addendum circle affect tooth thickness and engagement depth, while changes in the pitch circle directly alter the gear's operational geometry and load distribution.

Differences in Manufacturing Considerations

Addendum circle refers to the outermost circle that marks the tips of gear teeth, while the pitch circle represents the theoretical circle where gear teeth effectively engage. Manufacturing considerations differ as the addendum circle size impacts gear tooth height and clearance, influencing machining and heat treatment processes, whereas the pitch circle diameter dictates gear ratio and meshing precision, requiring accurate layout and tool alignment. Precise control of the pitch circle is critical for functional gear performance, whereas the addendum circle ensures proper tooth profile without interference.

Effects on Gearing Performance and Efficiency

Addendum circle and pitch circle are critical parameters in gear design that significantly affect gearing performance and efficiency. The addendum circle defines the outermost diameter of the gear teeth, influencing the gear's strength and load capacity, whereas the pitch circle represents the theoretical contact line where gears mesh, determining the gear ratio and smoothness of transmission. Variations between these circles impact friction, wear, and power loss, with optimal alignment enhancing efficiency by reducing vibration and ensuring precise torque transfer.

Common Applications and Usage Scenarios

Addendum circle and pitch circle are critical concepts in gear design, with the addendum circle representing the outermost boundary of gear teeth and the pitch circle serving as the fundamental reference where gear teeth theoretically engage. Common applications of the pitch circle include calculating gear ratios and ensuring proper meshing in mechanical systems such as automotive transmissions and industrial machinery. The addendum circle is essential for defining the gear tooth height and clearance, frequently used in scenarios involving wear analysis and manufacturing tolerances to optimize gear performance and longevity.

Conclusion: Key Takeaways and Practical Insights

Addendum circle defines the outermost boundary of gear teeth, impacting gear clearance and engagement, while the pitch circle serves as the theoretical base for gear dimensioning and velocity ratio determination. Accurate gear design depends on the precise calculation of both circles to ensure proper meshing, load distribution, and noise reduction. Integrating knowledge of addendum and pitch circles enhances gear performance and durability in mechanical applications.

Addendum circle Infographic

libterm.com

libterm.com