Flame hardening is a heat treatment process that improves the surface hardness of steel components by rapidly heating them with an oxy-fuel flame followed by quick quenching. This technique enhances wear resistance and fatigue strength while preserving the core's toughness, making it ideal for automotive and industrial applications. Discover how flame hardening can optimize your metal parts by exploring the detailed benefits and methods in the rest of this article.

Table of Comparison

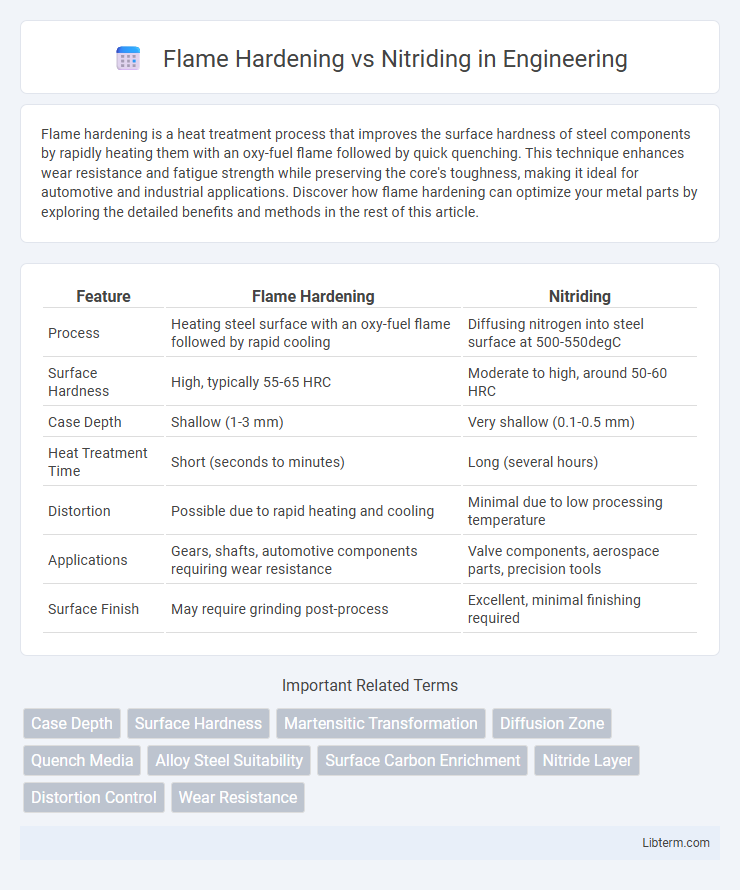

| Feature | Flame Hardening | Nitriding |

|---|---|---|

| Process | Heating steel surface with an oxy-fuel flame followed by rapid cooling | Diffusing nitrogen into steel surface at 500-550degC |

| Surface Hardness | High, typically 55-65 HRC | Moderate to high, around 50-60 HRC |

| Case Depth | Shallow (1-3 mm) | Very shallow (0.1-0.5 mm) |

| Heat Treatment Time | Short (seconds to minutes) | Long (several hours) |

| Distortion | Possible due to rapid heating and cooling | Minimal due to low processing temperature |

| Applications | Gears, shafts, automotive components requiring wear resistance | Valve components, aerospace parts, precision tools |

| Surface Finish | May require grinding post-process | Excellent, minimal finishing required |

Introduction to Surface Hardening Techniques

Surface hardening techniques such as flame hardening and nitriding enhance the wear resistance and fatigue strength of metal components by modifying their outer layers. Flame hardening involves rapidly heating the metal surface with an oxy-fuel flame followed by quenching, creating a hardened outer layer with improved toughness. Nitriding introduces nitrogen atoms into the metal surface at lower temperatures through a controlled gas or plasma process, resulting in increased surface hardness and corrosion resistance without distortion.

What is Flame Hardening?

Flame hardening is a surface hardening process that uses an oxy-fuel gas flame to rapidly heat the steel surface followed by immediate quenching, resulting in increased hardness and wear resistance in the treated area. This method is particularly effective for components requiring hard, wear-resistant surfaces like gears, shafts, and rails, without altering the core properties. Compared to nitriding, flame hardening achieves hardness through rapid thermal transformation, while nitriding relies on diffusing nitrogen into the steel surface at lower temperatures for enhanced surface strength.

What is Nitriding?

Nitriding is a surface hardening process that diffuses nitrogen into the surface of steel to create a hard, wear-resistant nitrided layer without the need for quenching. Unlike flame hardening, which uses direct flame to rapidly heat and then cool the metal surface, nitriding occurs at lower temperatures, typically between 500degC and 550degC, resulting in minimal distortion and improved fatigue resistance. This technique is especially effective for enhancing the hardness, corrosion resistance, and dimensional stability of components such as gears, crankshafts, and camshafts.

Key Differences Between Flame Hardening and Nitriding

Flame hardening uses an oxy-fuel flame to rapidly heat the surface of steel, creating a hardened layer through quenching, whereas nitriding diffuses nitrogen into the metal at lower temperatures for a case-hardened surface without quenching. Flame hardening is faster and suitable for large, thick parts needing wear resistance and toughness, while nitriding offers superior corrosion resistance and fatigue strength for precision components. Nitriding produces a harder, more uniform case depth with minimal distortion, while flame hardening results in a variable depth depending on heating time and intensity.

Material Compatibility: Flame Hardening vs Nitriding

Flame hardening is primarily compatible with low to medium carbon steels, as it selectively hardens the surface by rapid heating and quenching, enhancing wear resistance without altering the core properties. Nitriding suits alloy steels with specific alloying elements such as chromium, molybdenum, and aluminum, forming a hard nitride layer through diffusion at lower temperatures, which improves surface hardness and fatigue strength without distortion. Material selection depends on steel composition, desired hardness depth, and thermal sensitivity, making flame hardening ideal for simple carbon steels and nitriding preferable for alloyed steels requiring precise surface treatments.

Process Steps and Equipment Overview

Flame hardening involves heating the surface of steel using an oxy-fuel torch followed by rapid quenching with water or polymer to achieve a hardened layer, requiring precise flame control and a quenching system. Nitriding is a low-temperature thermochemical process where nitrogen diffuses into the surface of the steel in a controlled gas atmosphere or plasma environment, utilizing specialized gas nitriding furnaces or plasma nitriding equipment. Both processes require distinct machinery: flame hardening relies on portable heating and quenching tools, while nitriding demands sealed, temperature-controlled chambers with gas or plasma supply systems.

Hardness, Wear Resistance, and Depth of Case

Flame hardening achieves surface hardness typically between 55-65 HRC with a wear-resistant case depth ranging from 2 to 6 mm, ideal for rapid treatment of large components. Nitriding offers lower hardness levels around 700-1000 HV but provides superior wear resistance and corrosion resistance with a thinner case depth of 0.1 to 0.5 mm due to nitrogen diffusion. Flame hardening's deeper hardened layer benefits impact-prone parts, whereas nitriding excels in applications requiring dimensional stability and enhanced fatigue strength.

Cost Comparison: Flame Hardening vs Nitriding

Flame hardening typically incurs lower initial costs due to its faster processing times and minimal equipment requirements compared to nitriding, which involves longer cycles and specialized gas or plasma setups. Despite higher upfront expenses, nitriding offers superior surface wear resistance and fatigue strength, potentially reducing long-term maintenance and replacement costs. Evaluating the total cost of ownership reveals that flame hardening is more cost-effective for short-term applications, whereas nitriding proves economical for components requiring enhanced durability and extended service life.

Typical Applications and Industries

Flame hardening is commonly used in industries such as automotive, construction, and heavy machinery for applications including gear teeth, shafts, and rails where surface wear resistance and toughness are critical. Nitriding finds typical applications in aerospace, tooling, and molding industries, providing enhanced fatigue strength and corrosion resistance on components like valves, crankshafts, and dies. Both processes serve distinct purposes with flame hardening favored for thicker hardened layers in high-impact environments and nitriding chosen for precise, wear-resistant surfaces with minimal distortion.

Choosing the Right Surface Hardening Method

Choosing the right surface hardening method depends on factors such as desired hardness depth, wear resistance, and component size. Flame hardening suits large, heavy steel parts requiring deep hardening and rapid processing, while nitriding provides superior surface hardness and corrosion resistance with minimal distortion, ideal for precision components. Material composition, operational environment, and cost considerations also play critical roles in selecting between flame hardening and nitriding.

Flame Hardening Infographic

libterm.com

libterm.com