Rotational speed measures how fast an object spins around its axis, typically expressed in revolutions per minute (RPM) or radians per second. Understanding rotational speed is crucial for optimizing performance in machinery, engines, and various mechanical systems. Dive deeper into this article to explore how rotational speed impacts efficiency and design.

Table of Comparison

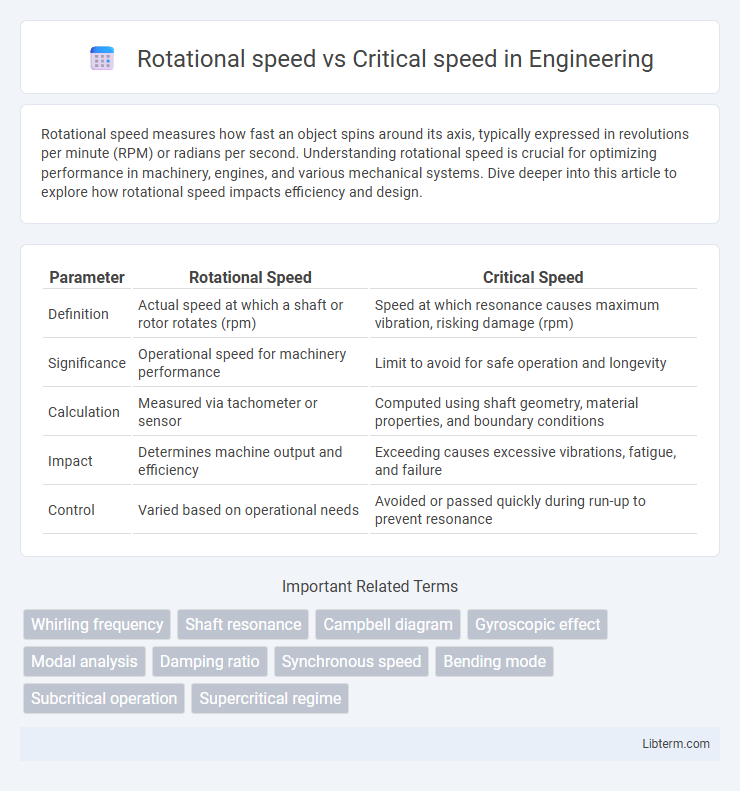

| Parameter | Rotational Speed | Critical Speed |

|---|---|---|

| Definition | Actual speed at which a shaft or rotor rotates (rpm) | Speed at which resonance causes maximum vibration, risking damage (rpm) |

| Significance | Operational speed for machinery performance | Limit to avoid for safe operation and longevity |

| Calculation | Measured via tachometer or sensor | Computed using shaft geometry, material properties, and boundary conditions |

| Impact | Determines machine output and efficiency | Exceeding causes excessive vibrations, fatigue, and failure |

| Control | Varied based on operational needs | Avoided or passed quickly during run-up to prevent resonance |

Introduction to Rotational Speed and Critical Speed

Rotational speed refers to the number of revolutions per minute (RPM) a rotating object completes, serving as a key parameter in machine operation and performance. Critical speed is the specific rotational speed at which a rotating shaft or rotor experiences resonance, leading to excessive vibration and potential structural failure. Understanding the relationship between rotational speed and critical speed is essential for designing safe and efficient rotating machinery components.

Defining Rotational Speed in Mechanical Systems

Rotational speed in mechanical systems refers to the number of revolutions per minute (RPM) a rotating component such as a shaft or rotor completes around its axis. This parameter is crucial for characterizing the operational velocity of machinery, influencing performance and efficiency. Understanding rotational speed aids in avoiding resonance phenomena associated with critical speed, the specific speed at which system vibrations amplify dangerously due to natural frequency matching.

Understanding Critical Speed: Concepts and Importance

Critical speed represents the rotational speed at which a rotating shaft or system experiences resonance, causing excessive vibrations and potential mechanical failure. Understanding this concept is essential for designing safe and reliable machinery, as operating near or at critical speed can lead to catastrophic damage. Engineers use critical speed calculations to avoid resonance conditions, ensuring optimal performance and longevity of rotating equipment.

Key Differences Between Rotational Speed and Critical Speed

Rotational speed refers to the actual speed at which a machine or component rotates, typically measured in revolutions per minute (RPM), while critical speed is the specific rotational speed at which a system experiences resonance, causing excessive vibration and potential damage. The key difference lies in the fact that rotational speed is an operational parameter, whereas critical speed is a threshold that should be avoided or carefully managed to maintain structural integrity. Understanding critical speed is crucial for designing rotating machinery to prevent failure and ensure safe, efficient operation.

Factors Influencing Rotational and Critical Speeds

Rotational speed and critical speed are influenced by factors such as shaft stiffness, material density, and geometric dimensions including length and diameter. Increased shaft rigidity elevates critical speed, while heavier mass or longer shafts tend to lower it by amplifying vibrational tendencies. Operating rotational speed close to or beyond the critical speed induces resonance, risking mechanical failure and emphasizing the necessity for precise calculation of these parameters in rotor dynamics.

Effects of Exceeding Critical Speed

Exceeding the critical speed of a rotating shaft causes severe vibrations due to resonance, leading to increased stress and potential structural failure. These excessive oscillations can result in bearing damage, misalignment, and reduced operational lifespan of machinery. Ensuring operational speeds remain below critical speed thresholds is essential for maintaining mechanical integrity and preventing catastrophic equipment damage.

Measurement Techniques for Rotational and Critical Speed

Measurement techniques for rotational and critical speeds involve precise instrumentation such as tachometers and vibration analyzers to capture real-time rotational velocity and identify resonance frequencies. Laser Doppler velocimetry and proximity probes offer high-resolution data, enabling detection of critical speeds where system vibrations peak, potentially leading to mechanical failure. Modal analysis combined with spin testing provides comprehensive insights into dynamic behavior, ensuring accurate assessment of both rotational and critical speeds in rotating machinery.

Applications: Practical Examples in Engineering

In engineering applications, rotational speed and critical speed are crucial in designing rotating machinery such as turbines, compressors, and shafts. Operating machinery below the critical speed ensures stability and prevents excessive vibrations that can cause structural damage or failure. For example, in pump shafts, maintaining rotational speed well below critical speed avoids resonance, prolonging equipment lifespan and optimizing performance.

Preventative Measures for Critical Speed Issues

Maintaining rotational speeds below the system's critical speed is essential to prevent resonance and excessive vibrations that can cause mechanical failure. Implementing vibration monitoring systems and performing regular balancing and alignment checks mitigate the risks associated with operating near critical speeds. Using damping techniques and selecting materials with appropriate stiffness also enhance the structural integrity and operational safety of rotating machinery.

Summary and Best Practices for Speed Management

Rotational speed refers to the actual operational velocity of a rotating component, while critical speed denotes the specific speed at which resonance causes maximum vibration and potential system failure. Maintaining rotational speed well below the critical speed enhances equipment stability and extends bearing life by minimizing dynamic stress. Best practices for speed management include regular vibration analysis, implementing speed sensors for real-time monitoring, and designing equipment with safety margins to avoid critical speed regions.

Rotational speed Infographic

libterm.com

libterm.com