The Pratt truss is a popular structural design used in bridges, characterized by its diagonal members which slope towards the center and handle tension, while vertical members manage compression. This configuration provides an efficient balance of strength and material use, making it suitable for medium to long spans. Explore the rest of the article to uncover how the Pratt truss can enhance your engineering projects.

Table of Comparison

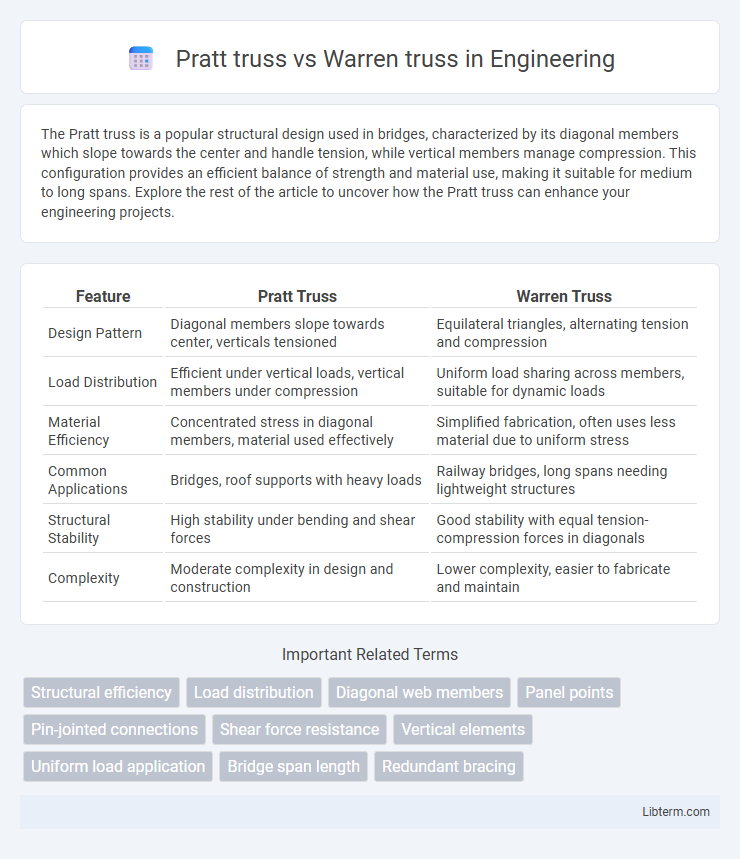

| Feature | Pratt Truss | Warren Truss |

|---|---|---|

| Design Pattern | Diagonal members slope towards center, verticals tensioned | Equilateral triangles, alternating tension and compression |

| Load Distribution | Efficient under vertical loads, vertical members under compression | Uniform load sharing across members, suitable for dynamic loads |

| Material Efficiency | Concentrated stress in diagonal members, material used effectively | Simplified fabrication, often uses less material due to uniform stress |

| Common Applications | Bridges, roof supports with heavy loads | Railway bridges, long spans needing lightweight structures |

| Structural Stability | High stability under bending and shear forces | Good stability with equal tension-compression forces in diagonals |

| Complexity | Moderate complexity in design and construction | Lower complexity, easier to fabricate and maintain |

Introduction to Truss Bridge Designs

Pratt truss and Warren truss are two fundamental types of truss bridge designs commonly used in civil engineering. The Pratt truss features vertical members in compression and diagonal members in tension, making it efficient for longer spans and heavy loads. In contrast, the Warren truss uses equilateral triangles with alternating tension and compression forces, providing a simpler, lighter structure ideal for moderate spans.

What is a Pratt Truss?

A Pratt truss is a type of structural framework used primarily in bridge construction, characterized by diagonal members that slope towards the center and handle tension, while vertical members handle compression. This design efficiently distributes loads, making it ideal for longer spans and heavy loads due to its economical use of materials and ease of construction. Compared to the Warren truss, which uses equilateral triangles and handles both tension and compression in diagonals, the Pratt truss offers better performance under varying load conditions.

What is a Warren Truss?

A Warren truss is a structural framework consisting of equilateral triangles that distribute loads evenly through alternating tension and compression members. This design eliminates vertical members, making it efficient for bridges and roof supports by reducing material use while maintaining strength. Its uniform triangular pattern contrasts with the Pratt truss, which uses vertical compression members and diagonal tension members for different load distribution.

Historical Background of Pratt and Warren Trusses

The Pratt truss, designed in 1844 by Thomas and Caleb Pratt, features diagonal members that slope toward the center of the span under tension and vertical members under compression, making it ideal for railroad bridges in the 19th century. The Warren truss, patented by James Warren and Willoughby Monzani in 1848, employs a series of equilateral triangles without vertical members, offering a more material-efficient design used widely in highway bridges and industrial applications. Both truss types significantly influenced bridge engineering during the Industrial Revolution, with the Pratt truss emphasizing ease of construction and the Warren truss optimizing structural efficiency.

Structural Differences: Pratt vs Warren Truss

The Pratt truss features diagonal members that slope towards the center, primarily designed to handle tension, while vertical members handle compression, optimizing its use for longer spans with heavy loads. The Warren truss consists of equilateral triangles with diagonal members alternating in tension and compression, offering uniform stress distribution and efficient material use in shorter spans. Structurally, the Pratt truss relies on verticals for compression and diagonals for tension, whereas the Warren truss balances forces more evenly across its members without verticals.

Load Distribution Analysis

The Pratt truss features vertical members under compression and diagonal members under tension, optimizing load distribution for heavier vertical loads while providing efficient resistance to bending moments. In contrast, the Warren truss utilizes equilateral triangles with members subjected primarily to axial forces alternating between tension and compression, promoting uniform load distribution and efficient material usage. Load distribution analysis reveals the Pratt truss excels in scenarios with predominant vertical loads, whereas the Warren truss offers superior performance in evenly distributed load conditions.

Material Efficiency and Cost Comparison

Pratt truss designs utilize diagonal members that primarily experience tension, allowing for the use of slender, less material-intensive components, resulting in enhanced material efficiency compared to Warren trusses. Warren truss configurations distribute loads evenly through equilateral triangles, often requiring less complex connections, which can reduce fabrication and erection costs. Cost comparison shows Pratt trusses may incur higher initial expenses due to more intricate joint work, while Warren trusses offer cost savings in standardization and ease of construction, making the latter more economical in large-scale or repetitive projects.

Advantages of Pratt Truss

The Pratt truss offers superior efficiency in handling dynamic loads due to its diagonal members being primarily under tension, which enhances structural stability and reduces material stress. Its design simplifies construction and maintenance compared to the Warren truss, as the vertical members bear compression forces, allowing easier inspection and repair. The Pratt truss is particularly advantageous for bridges with longer spans, providing better load distribution and scalability in various engineering applications.

Advantages of Warren Truss

The Warren truss offers superior load distribution through its equilateral triangular design, minimizing bending moments and enhancing structural efficiency. Its simplicity in fabrication and fewer components reduce construction costs and maintenance requirements compared to the Pratt truss. The uniform stress in the Warren truss members allows for lighter materials, leading to overall weight savings and increased durability in bridge and roof structures.

Choosing the Right Truss for Your Project

Pratt truss designs excel in handling heavy loads and are ideal for bridges and large structures where tension is a key factor, offering efficient material use and straightforward construction. Warren truss configurations distribute loads evenly through equilateral triangles, making them suitable for lighter spans with uniform stress distribution and aesthetic appeal. Selecting the right truss depends on project-specific factors such as load requirements, span length, material availability, and structural efficiency.

Pratt truss Infographic

libterm.com

libterm.com