Direct wiring offers a straightforward and reliable method for connecting electrical components without the need for additional connectors or terminals. This approach minimizes potential points of failure and can improve the overall efficiency and safety of your electrical system. Explore the rest of the article to learn how to implement direct wiring correctly and its benefits for your projects.

Table of Comparison

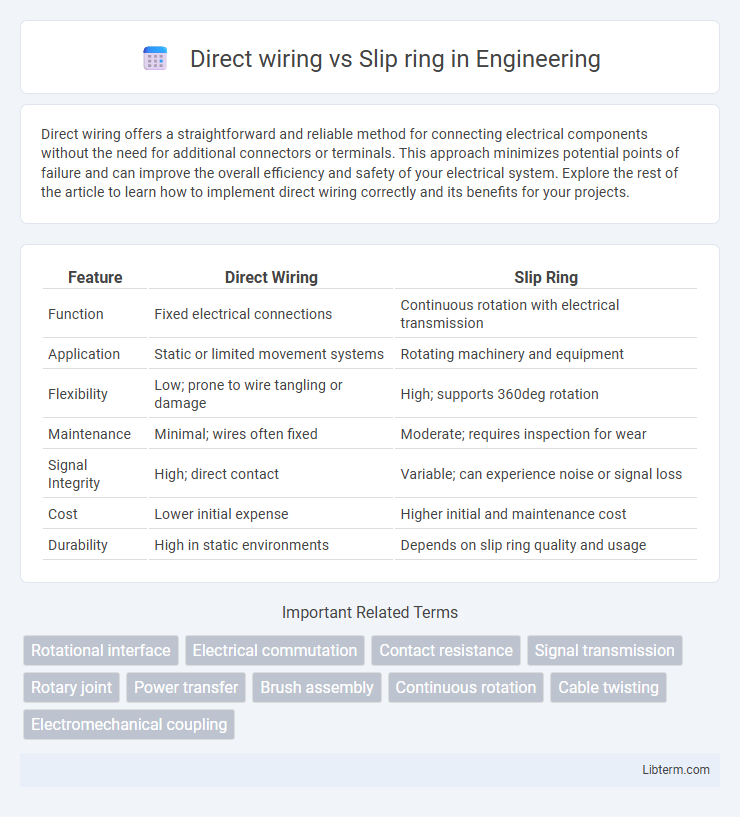

| Feature | Direct Wiring | Slip Ring |

|---|---|---|

| Function | Fixed electrical connections | Continuous rotation with electrical transmission |

| Application | Static or limited movement systems | Rotating machinery and equipment |

| Flexibility | Low; prone to wire tangling or damage | High; supports 360deg rotation |

| Maintenance | Minimal; wires often fixed | Moderate; requires inspection for wear |

| Signal Integrity | High; direct contact | Variable; can experience noise or signal loss |

| Cost | Lower initial expense | Higher initial and maintenance cost |

| Durability | High in static environments | Depends on slip ring quality and usage |

Introduction to Direct Wiring and Slip Ring

Direct wiring involves establishing a fixed electrical connection between components using cables or wires, ensuring a stable and reliable signal or power transmission with minimal maintenance. Slip rings are electromechanical devices that enable the transmission of power and electrical signals from a stationary to a rotating structure, crucial in applications requiring continuous rotation such as wind turbines and robotics. Both direct wiring and slip rings serve distinct roles in electrical systems, with direct wiring favored for stationary setups and slip rings essential for dynamic, rotating mechanisms.

Key Differences Between Direct Wiring and Slip Ring

Direct wiring offers a fixed electrical connection typically used in applications with limited or no rotational movement, ensuring simplicity and minimal maintenance. Slip rings enable continuous electrical power and signal transmission in rotating systems by utilizing conductive rings and brushes, allowing 360-degree rotation without cable entanglement. The key differences include their operational use cases, with direct wiring suited for static or limited movement setups, while slip rings are essential for applications requiring unrestricted rotation.

How Direct Wiring Works

Direct wiring involves connecting electrical components through a fixed, continuous conductor without any rotating interfaces, ensuring uninterrupted power and signal transmission. The system relies on rigid cables and connectors securely attached to stationary parts, minimizing noise and signal loss. This approach is ideal for applications where rotation is limited or non-existent, offering simplicity and high reliability in power delivery.

How Slip Rings Function

Slip rings function by maintaining an electrical connection between stationary and rotating components through conductive rings and brushes, enabling continuous power and signal transmission in rotating machinery. Unlike direct wiring, which relies on fixed wires that can twist and wear out, slip rings allow for unrestricted rotation without cable entanglement or damage. This mechanism is essential in applications such as wind turbines, robotics, and rotary sensors where uninterrupted 360-degree rotation is required.

Advantages of Direct Wiring

Direct wiring offers superior electrical efficiency and reliability by minimizing signal loss and electrical noise compared to slip rings. This method reduces maintenance requirements since it eliminates the mechanical wear and potential failure points inherent in slip rings. Direct wiring also supports higher current capacities and better insulation, making it ideal for high-performance applications.

Benefits of Using Slip Rings

Slip rings provide continuous electrical connection between stationary and rotating parts, enabling uninterrupted power and data transmission. They minimize wear and maintenance compared to direct wiring by eliminating cable twisting and tangling in rotating machinery. Enhanced reliability and flexibility in complex equipment such as wind turbines and robotics make slip rings a preferred choice over direct wiring systems.

Common Applications: Direct Wiring vs Slip Ring

Direct wiring is commonly used in fixed or limited-movement applications such as electronic enclosures, control panels, and static machinery where reliable, simple, and low-maintenance connections are essential. Slip rings find frequent application in rotating equipment like wind turbines, rotary tables, and robotic arms, enabling continuous electrical transmission through rotating interfaces without cable entanglement. Industries such as aerospace, packaging, and medical devices rely on slip rings for seamless power and signal transfer in dynamic environments requiring 360-degree rotation.

Limitations and Challenges

Direct wiring faces limitations in applications requiring continuous rotation, as cable twisting can lead to wear and signal degradation. Slip rings overcome this by allowing uninterrupted power and data transfer during rotation but present challenges such as mechanical wear, electrical noise, and maintenance requirements. Both systems require careful consideration of operational environment, rotational speed, and signal integrity to ensure reliable performance.

Choosing the Right Solution for Your Project

Choosing between direct wiring and slip rings depends on the project's rotational requirements and electrical complexity. Direct wiring suits applications with limited rotation and lower signal counts, offering simplicity and cost-effectiveness, while slip rings support continuous 360-degree rotation and multiple conductive paths, ideal for dynamic systems like wind turbines or robotics. Evaluating factors such as rotational speed, signal integrity, maintenance needs, and environmental conditions ensures the optimal solution for reliable electrical connectivity.

Conclusion: Direct Wiring vs Slip Ring

Direct wiring offers a straightforward and cost-effective solution for static or limited-rotation applications, providing reliable electrical connections without complex components. Slip rings are essential for rotating systems requiring continuous electrical transmission, enabling uninterrupted power and signal flow with increased mechanical complexity and maintenance needs. Choosing between direct wiring and slip rings depends on the application's rotational requirements, durability demands, and budget constraints.

Direct wiring Infographic

libterm.com

libterm.com