Rolling friction occurs when a round object, such as a wheel or ball, rolls over a surface, creating resistance that opposes motion. This type of friction is generally lower than sliding friction, making it essential for efficient movement in vehicles and machinery. Explore the following article to understand how rolling friction impacts your daily life and mechanical systems.

Table of Comparison

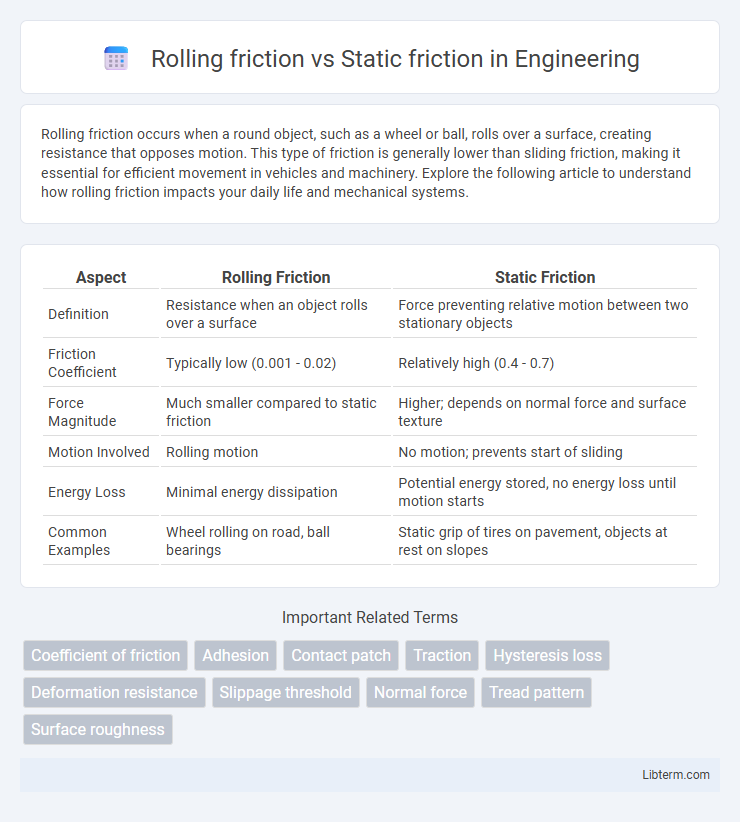

| Aspect | Rolling Friction | Static Friction |

|---|---|---|

| Definition | Resistance when an object rolls over a surface | Force preventing relative motion between two stationary objects |

| Friction Coefficient | Typically low (0.001 - 0.02) | Relatively high (0.4 - 0.7) |

| Force Magnitude | Much smaller compared to static friction | Higher; depends on normal force and surface texture |

| Motion Involved | Rolling motion | No motion; prevents start of sliding |

| Energy Loss | Minimal energy dissipation | Potential energy stored, no energy loss until motion starts |

| Common Examples | Wheel rolling on road, ball bearings | Static grip of tires on pavement, objects at rest on slopes |

Introduction to Friction: An Overview

Friction is a resistive force that opposes the relative motion or tendency of motion between two surfaces in contact. Static friction acts when surfaces are at rest relative to each other, preventing the initiation of sliding motion, while rolling friction occurs when an object rolls over a surface, typically producing less resistance than static or sliding friction. Understanding the differences between rolling friction and static friction is essential in applications ranging from vehicle movement to machinery efficiency.

Defining Rolling Friction

Rolling friction refers to the resistance experienced by a rolling object when it moves over a surface, caused primarily by deformation of the object and the surface at the contact point. This type of friction is generally much lower than static friction, which resists the initiation of motion between two stationary surfaces in contact. Understanding rolling friction is crucial in applications involving wheels, bearings, and ball bearings to reduce energy loss and improve efficiency.

Understanding Static Friction

Static friction is the force that resists the initiation of motion between two surfaces in contact, preventing an object from starting to slide. It acts in response to applied forces up to a maximum limit determined by the coefficient of static friction and the normal force. Understanding static friction is crucial for analyzing scenarios such as an object at rest on an inclined plane, where it balances the component of gravitational force parallel to the surface to maintain equilibrium.

Key Differences Between Rolling and Static Friction

Rolling friction occurs when an object rolls over a surface, typically producing less resistance compared to static friction, which acts between two surfaces at rest relative to each other, preventing the start of motion. Static friction is usually higher because it must counteract the initial force to overcome inertia, while rolling friction is influenced by factors such as the deformation of the rolling object and surface irregularities. Understanding these differences is crucial in applications like vehicle tire design, where minimizing rolling friction improves efficiency, whereas static friction ensures grip and prevents slipping.

Factors Affecting Rolling Friction

Rolling friction depends on factors such as surface texture, wheel radius, and material deformation at the contact point. Increased rigidity of the rolling object and smoother, harder surfaces reduce rolling resistance. Load weight influences the degree of material deformation, directly impacting the magnitude of rolling friction.

Factors Influencing Static Friction

Static friction depends on the nature of the surfaces in contact and the normal force pressing them together, with rougher textures and higher pressures increasing frictional force. Surface material properties, including hardness and microscopic surface roughness, play a crucial role in determining the maximum static friction before motion begins. Environmental factors such as temperature and presence of lubricants also affect the molecular interactions that govern static friction levels.

Real-World Examples of Rolling Friction

Rolling friction occurs when an object like a car tire or a ball rolls over a surface, significantly reducing resistance compared to static friction which acts on stationary objects. For example, bicycle tires experience rolling friction that allows smooth movement over pavement, whereas brakes rely on static friction to stop the vehicle by preventing wheel rotation. In applications such as conveyor belts and ball bearings, rolling friction minimizes energy loss and wear, enhancing efficiency and durability in mechanical systems.

Practical Applications of Static Friction

Static friction plays a crucial role in practical applications such as vehicle tire traction, where it prevents slipping during acceleration and braking on road surfaces. It also ensures stability in structures by resisting initial motion between contact surfaces, as seen in stair treads and furniture support. In machinery, static friction allows gears and belts to transmit force efficiently without slipping, enabling smooth operation.

Reducing and Increasing Friction: Methods and Materials

Reducing rolling friction is effectively achieved by using smooth, hard surfaces and lubricants like grease or oil to minimize deformation and resistance between the rolling object and the surface. Increasing static friction involves using rougher surfaces, materials with high friction coefficients such as rubber, or adding adhesives to enhance grip and prevent slipping. Materials like Teflon or polished metals are preferred for reducing friction, while rubber or textured metals are ideal for increasing static friction for better stability and control.

Conclusion: Choosing Between Rolling and Static Friction

Choosing between rolling friction and static friction depends on the application's requirements for motion and energy efficiency. Rolling friction typically offers lower resistance, making it ideal for moving objects with minimal energy loss, while static friction is crucial for preventing unwanted motion and providing strong grip. Understanding the balance between these friction types optimizes performance in mechanical systems, transportation, and material handling.

Rolling friction Infographic

libterm.com

libterm.com