Buttress threads provide exceptional strength and durability by combining the load-bearing capacity of square threads with the ease of manufacture of triangular threads. Ideal for applications involving high axial forces, these threads efficiently transmit one-directional loads, making them essential in heavy machinery and structural supports. Explore the rest of the article to learn how buttress threads can enhance your mechanical designs.

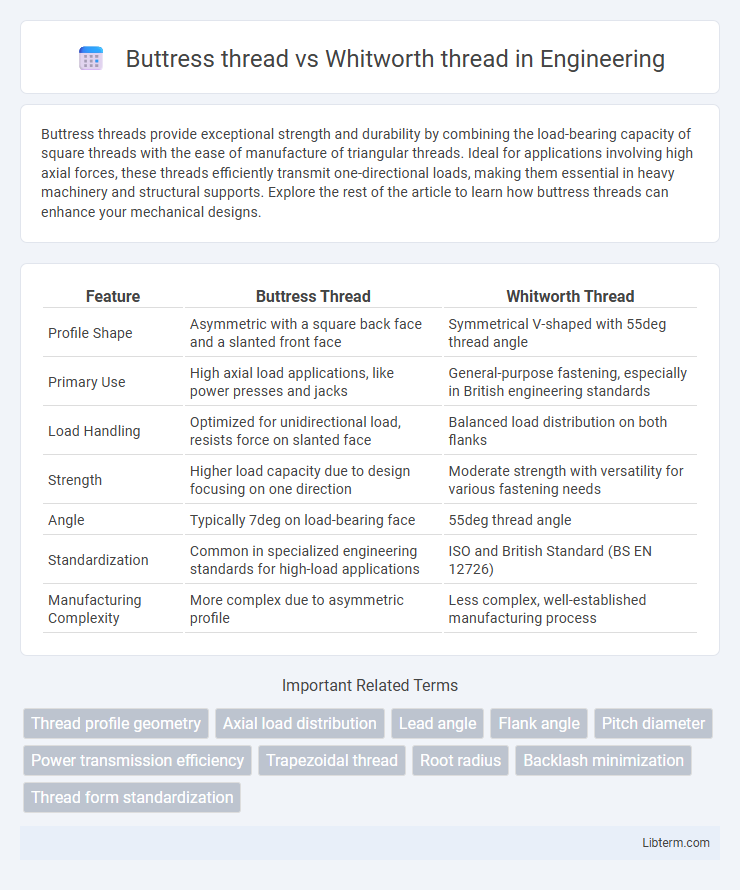

Table of Comparison

| Feature | Buttress Thread | Whitworth Thread |

|---|---|---|

| Profile Shape | Asymmetric with a square back face and a slanted front face | Symmetrical V-shaped with 55deg thread angle |

| Primary Use | High axial load applications, like power presses and jacks | General-purpose fastening, especially in British engineering standards |

| Load Handling | Optimized for unidirectional load, resists force on slanted face | Balanced load distribution on both flanks |

| Strength | Higher load capacity due to design focusing on one direction | Moderate strength with versatility for various fastening needs |

| Angle | Typically 7deg on load-bearing face | 55deg thread angle |

| Standardization | Common in specialized engineering standards for high-load applications | ISO and British Standard (BS EN 12726) |

| Manufacturing Complexity | More complex due to asymmetric profile | Less complex, well-established manufacturing process |

Introduction to Buttress and Whitworth Threads

Buttress threads feature an asymmetrical profile with a 45-degree load-bearing face designed for transmitting high axial forces, commonly used in heavy machinery and jackscrews. Whitworth threads have a symmetrical 55-degree thread angle with rounded crests and roots, developed as one of the first standardized screw thread forms primarily for general engineering applications. Both thread types serve specific mechanical purposes, with Buttress threads optimized for strength in one direction and Whitworth threads known for uniform load distribution and wear resistance.

Historical Development of Screw Threads

Buttress threads were developed in the early 20th century to provide high axial load capacity with reduced friction, commonly used in heavy machinery and hydraulic systems. Whitworth threads, invented by Joseph Whitworth in 1841, represent the first standardized screw thread profile, establishing a 55-degree thread angle that became widely adopted across the British Empire. The historical evolution of these threads reflects the shift from general-purpose fastening (Whitworth) to specialized, high-load applications (Buttress).

Profile and Geometry: Buttress vs Whitworth

Buttress threads feature an asymmetric profile with one face nearly perpendicular to the axis, designed to handle high axial loads in one direction, typically used in heavy machinery and screw jacks. Whitworth threads have a symmetrical 55-degree thread angle with rounded crests and roots, promoting smoother engagement and uniform stress distribution, commonly found in British-standard pipe fittings and fasteners. The geometric distinction lies in Buttress threads' load-bearing capability with a distinct load face, whereas Whitworth threads emphasize interchangeability and sealing with their rounded, uniform profile.

Strength and Load-Bearing Capabilities

Buttress threads excel in strength and load-bearing capabilities due to their asymmetric profile, which efficiently handles high axial loads in one direction, making them ideal for heavy-duty applications like hydraulic jacks and screw presses. Whitworth threads, with their rounded profile and 55-degree angle, provide moderate strength and load distribution, primarily suited for general fastening purposes where balanced load handling is required. The geometry of Buttress threads minimizes shear stress and enhances durability under heavy tension, outperforming Whitworth threads in applications demanding superior axial load resistance.

Typical Applications in Industry

Buttress threads are widely used in high-load applications such as hydraulic systems, heavy machinery, and aerospace components due to their ability to withstand axial thrust in one direction. Whitworth threads are commonly found in British engineering and automotive industries, particularly in pipe fittings, fasteners, and machinery where a standard thread angle and robust engagement are required. The choice between Buttress and Whitworth threads depends on the specific mechanical demands and directional load requirements of the industrial application.

Thread Manufacturing Techniques

Buttress thread manufacturing involves precision grinding and thread rolling processes that form a strong, load-bearing profile ideal for high-stress applications, emphasizing a single load direction with asymmetric thread flanks. Whitworth thread production typically employs cutting or rolling techniques designed for a symmetrical 55-degree thread angle with rounded crests and roots, optimizing durability and ease of assembly in general-purpose fastening. Both methods require precise control of threading tools and machinery to maintain profile accuracy and ensure compatibility with corresponding fasteners.

Advantages of Buttress Threads

Buttress threads offer superior load-bearing capacity due to their asymmetric profile, which efficiently handles high axial thrust in one direction, making them ideal for applications like hydraulic presses and jacks. Their design reduces friction and wear by distributing stress more evenly along the thread, enhancing durability compared to Whitworth threads. Buttress threads also provide easier assembly and disassembly under heavy loads, improving maintenance efficiency in industrial machinery.

Advantages of Whitworth Threads

Whitworth threads provide superior strength due to their rounded roots and flanks, which reduce stress concentrations and increase fatigue resistance. Their standardized 55-degree thread angle ensures better compatibility and interchangeability across British and Commonwealth engineering applications. Whitworth threads also offer easier manufacturing and improved sealing properties compared to Buttress threads, making them ideal for high-pressure and precision fittings.

Limitations and Drawbacks of Each Thread Type

Buttress threads offer excellent load-carrying capacity in one direction but suffer from weaker resistance to lateral forces, making them less suitable for dynamic or multi-directional loads. Whitworth threads provide good strength and ease of manufacturing due to their rounded profile but have lower efficiency and higher friction compared to modern thread forms, limiting their use in high-torque applications. Both thread types face limitations in sealing capabilities and are less compatible with automated assembly processes than contemporary thread standards.

Choosing the Right Thread for Your Application

Choosing the right thread for your application depends on load direction and strength requirements; Buttress threads excel in handling high axial thrust in one direction, making them ideal for heavy-duty machinery and hydraulic systems. Whitworth threads, with their rounded profile and standardized 55-degree angle, offer strong resistance to fatigue and are suited for general-purpose fasteners in mechanical and automotive applications. Understanding the load type, environmental conditions, and strength needs ensures the selection of the most efficient thread form for durability and performance.

Buttress thread Infographic

libterm.com

libterm.com