Deformation refers to the change in shape or size of a material under applied forces or stress, affecting its structural integrity and performance. Understanding different types, such as elastic, plastic, and brittle deformation, is crucial for engineering and material science. Explore the rest of the article to learn how deformation impacts your projects and materials in practical applications.

Table of Comparison

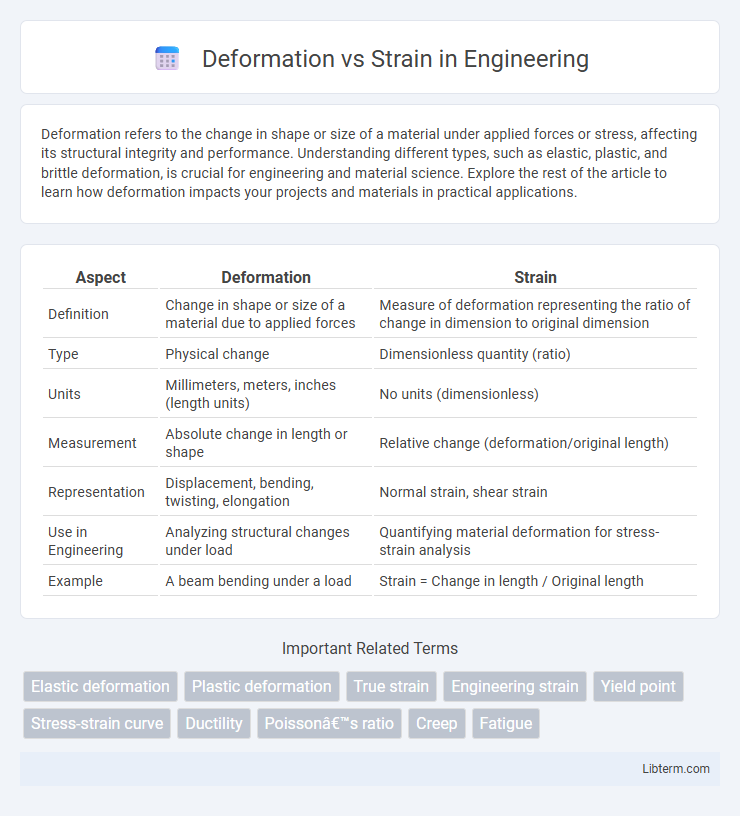

| Aspect | Deformation | Strain |

|---|---|---|

| Definition | Change in shape or size of a material due to applied forces | Measure of deformation representing the ratio of change in dimension to original dimension |

| Type | Physical change | Dimensionless quantity (ratio) |

| Units | Millimeters, meters, inches (length units) | No units (dimensionless) |

| Measurement | Absolute change in length or shape | Relative change (deformation/original length) |

| Representation | Displacement, bending, twisting, elongation | Normal strain, shear strain |

| Use in Engineering | Analyzing structural changes under load | Quantifying material deformation for stress-strain analysis |

| Example | A beam bending under a load | Strain = Change in length / Original length |

Introduction to Deformation and Strain

Deformation refers to the alteration in the shape or size of a material under applied forces, encompassing both elastic and plastic changes. Strain quantifies this deformation as the ratio of change in dimension to the original dimension, expressed as a dimensionless measure. Understanding deformation and strain is essential for analyzing material behavior, structural integrity, and mechanical performance in engineering applications.

Defining Deformation in Materials Science

Deformation in materials science refers to the change in shape or size of a material under the action of applied forces or stress. It involves the displacement of particles within the material, resulting in structural changes that can be temporary or permanent. Understanding deformation is crucial for analyzing material behavior under loads and predicting failure mechanisms in engineering applications.

Understanding Strain: Types and Significance

Strain measures the deformation of materials as a dimensionless ratio representing relative displacement between particles under stress. Types of strain include normal strain, which relates to elongation or compression, and shear strain, which involves angular distortion. Understanding strain is crucial for analyzing material behavior under load, predicting failure, and designing resilient structures.

Key Differences Between Deformation and Strain

Deformation refers to the overall change in the shape or size of a material under applied force, encompassing both elastic and plastic changes. Strain specifically measures the amount of deformation relative to the original dimensions of the material, expressed as a dimensionless ratio or percentage. The key difference lies in deformation being a physical change while strain quantifies that change in a standardized form.

Causes and Factors Influencing Deformation

Deformation occurs when external forces or loads cause a change in the shape or size of a material, driven primarily by stress exceeding the material's elastic limit. Strain measures the extent of deformation as a dimensionless ratio of change in length to original length, reflecting the material's response to applied stress. Factors influencing deformation include material properties such as elasticity, temperature, loading rate, and the presence of flaws or microstructural defects.

Measuring and Calculating Strain

Strain is a dimensionless quantity that measures deformation as the ratio of change in length to the original length of a material under stress. It is calculated using the formula e = DL / L0, where e represents strain, DL is the change in length, and L0 is the initial length. Measurement techniques for strain include strain gauges, which convert mechanical deformation into electrical signals for precise quantification.

Effects of Deformation on Material Properties

Deformation alters the internal structure of materials, causing changes in mechanical properties such as hardness, ductility, and tensile strength. Plastic deformation generates dislocations that increase material hardness through work hardening but reduce ductility. Elastic deformation, being reversible, does not permanently affect material properties but influences stress distribution within the material.

Real-World Applications of Deformation and Strain Analysis

Deformation and strain analysis are crucial in structural engineering for assessing the integrity of bridges, buildings, and aircraft under load, ensuring safety and durability. In manufacturing, monitoring deformation and strain helps optimize metal forming processes, preventing material failure and maintaining product quality. Geotechnical engineers use strain data to evaluate soil stability and predict landslides or ground settlement, safeguarding infrastructure and communities.

Common Testing Methods for Deformation and Strain

Common testing methods for deformation and strain include tensile testing, which measures elongation under axial load, and strain gauge techniques that quantify surface strain by converting mechanical deformation into electrical signals. Digital image correlation (DIC) is another widely used non-contact optical method that captures full-field deformation patterns by analyzing surface displacement. Ultrasonic testing and X-ray diffraction offer advanced approaches for internal strain measurement, providing detailed insight into microstructural changes.

Conclusion: Importance in Engineering and Material Design

Understanding the distinction between deformation and strain is crucial in engineering and material design for predicting material behavior under various loads. Accurate measurement of strain allows engineers to assess structural integrity and optimize material selection to prevent failure. Incorporating deformation and strain analysis enhances durability and safety, ensuring efficient and reliable performance of engineered systems.

Deformation Infographic

libterm.com

libterm.com