Bending is a fundamental mechanical process involving the deformation of materials under an applied force, typically resulting in a curved shape. Understanding the principles of bending is essential for applications in engineering, construction, and manufacturing to ensure structural integrity and performance. Discover how mastering bending techniques can enhance your projects by reading the rest of the article.

Table of Comparison

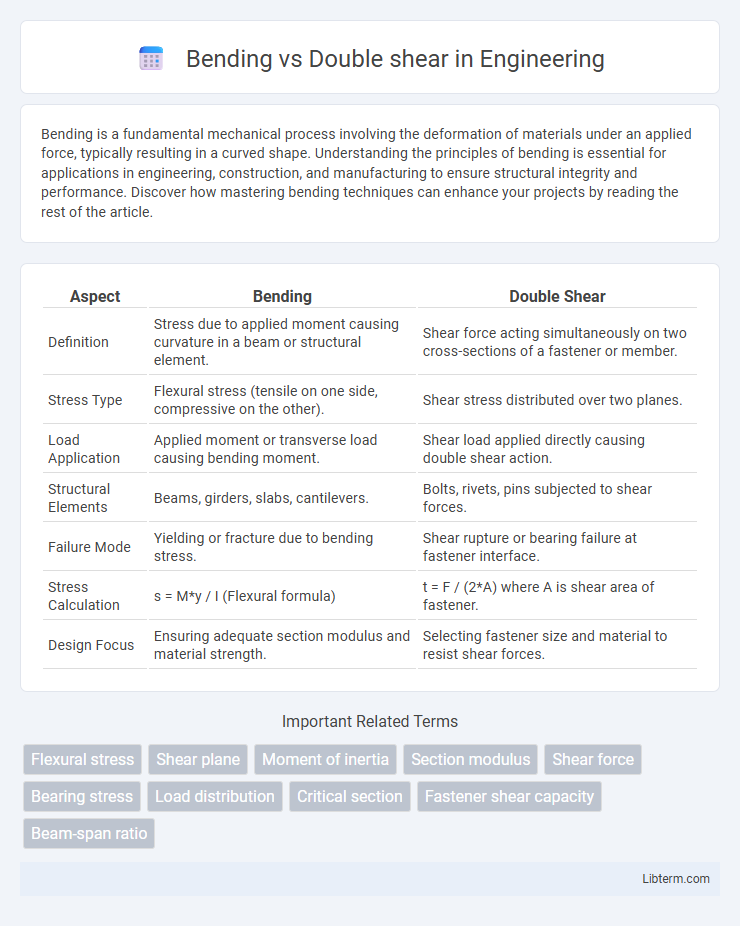

| Aspect | Bending | Double Shear |

|---|---|---|

| Definition | Stress due to applied moment causing curvature in a beam or structural element. | Shear force acting simultaneously on two cross-sections of a fastener or member. |

| Stress Type | Flexural stress (tensile on one side, compressive on the other). | Shear stress distributed over two planes. |

| Load Application | Applied moment or transverse load causing bending moment. | Shear load applied directly causing double shear action. |

| Structural Elements | Beams, girders, slabs, cantilevers. | Bolts, rivets, pins subjected to shear forces. |

| Failure Mode | Yielding or fracture due to bending stress. | Shear rupture or bearing failure at fastener interface. |

| Stress Calculation | s = M*y / I (Flexural formula) | t = F / (2*A) where A is shear area of fastener. |

| Design Focus | Ensuring adequate section modulus and material strength. | Selecting fastener size and material to resist shear forces. |

Introduction to Bending and Double Shear

Bending occurs when a structural element experiences a force that causes it to curve or deflect, resulting in internal stresses that vary along the cross-section. Double shear involves two parallel shear planes where the load is distributed, often found in fastener connections like bolts or rivets, effectively reducing the shear stress on each plane. Understanding the differences between bending moments and double shear forces is crucial for designing safe and efficient structural components.

Fundamental Concepts of Bending

Bending involves the deformation of a beam or structural element under load, causing tensile and compressive stresses across its cross-section, primarily governed by the bending moment and section modulus. Double shear refers to a type of shear failure where a fastener or joint experiences shear forces on two planes, effectively doubling the shear capacity compared to single shear. Understanding the fundamental concepts of bending is crucial for designing beams that resist bending moments without excessive deflection or failure, ensuring structural integrity.

Understanding Double Shear Mechanisms

Double shear occurs when a fastener or material element is subjected to shear forces across two planes, effectively distributing the load and increasing the joint's overall strength compared to single shear or bending scenarios. Unlike bending, which induces tensile and compressive stresses causing material deformation or failure, double shear primarily focuses on resisting sliding forces that act parallel to the cross-sectional area, minimizing bending moments. Understanding double shear mechanisms is crucial for designing robust connections in structural engineering, ensuring components withstand shear loads without excessive deformation or failure.

Key Differences Between Bending and Double Shear

Bending involves the deformation of a material when a moment or bending force is applied, causing tension on one side and compression on the other, while double shear occurs when a force causes a material to fail in two shear planes simultaneously, distributing the load across both planes. Key differences include the type of stress--bending stresses involve tensile and compressive stresses, whereas double shear stresses involve shear forces. Structural elements subjected to bending experience curvature and deflection, whereas components in double shear are primarily loaded in shear without significant bending deformation.

Material Behavior Under Bending and Double Shear

Material behavior under bending involves tensile stress on one side and compressive stress on the opposite side, causing deformation and potential failure when stress exceeds yield strength. In double shear, the material experiences shear stress distributed over two planes, reducing stress concentration and enhancing load capacity. Understanding these stress distributions is crucial for optimizing material selection and structural design in engineering applications.

Applications of Bending in Engineering

Bending in engineering is extensively used in the design of beams, bridges, and structural frameworks where materials must resist deformation under load. Applications include the construction of cantilever beams in buildings, automotive chassis components, and aircraft wings, all requiring precise bending stress analysis to ensure durability. Double shear, contrastingly, is commonly applied in fastener and joint design to evaluate resistance against forces attempting to slide connected parts apart.

Applications of Double Shear in Structures

Double shear provides enhanced load distribution and increased strength in structural connections, making it ideal for critical applications such as beam-to-column joints and truss connections. Commonly utilized in steel frameworks and timber structures, double shear links improve resistance to shearing forces by effectively splitting the load across two shear planes. This ensures greater stability and durability in bridges, roof trusses, and heavy machinery supports where safety and load-bearing capacity are paramount.

Failure Modes: Bending vs Double Shear

Failure modes in bending typically involve tension-induced fracture on the convex side and compression yielding on the concave side, whereas double shear failure primarily occurs through material rupture or yielding along two shear planes. In bending, stress distribution causes progressive micro-cracks leading to flexural failure, while double shear failure results from the simultaneous shear stresses exceeding the shear strength along the connected cross-sections. Understanding these distinct failure mechanisms is critical for designing components subjected to complex loading conditions.

Design Considerations for Bending and Double Shear

Design considerations for bending emphasize selecting appropriate beam dimensions, material strength, and moment capacity to resist deformation and failure under applied loads. Double shear design focuses on ensuring adequate cross-sectional area, bolt arrangement, and shear strength to prevent shear failure at the connection points. Proper load distribution, factor of safety, and compliance with relevant structural codes are critical for both bending and double shear designs to ensure structural integrity and durability.

Summary and Engineering Best Practices

Bending stress occurs when a structural element is subjected to a moment causing it to curve, typically analyzed using the flexural formula to ensure material limits are not exceeded. Double shear involves a force being applied in such a way that two shear planes develop, effectively doubling the shear area and increasing load capacity compared to single shear. Engineering best practices recommend selecting the appropriate failure mode based on loading conditions, using precise calculations for bending moments and shear forces, and incorporating safety factors to prevent structural failure.

Bending Infographic

libterm.com

libterm.com