Lap joints provide a strong and stable connection by overlapping two pieces of material, commonly used in woodworking and metalworking for enhanced durability. These joints distribute stress evenly across the overlapping area, making them ideal for frameworks and structural applications. Explore the detailed techniques and benefits of lap joints to improve your construction projects.

Table of Comparison

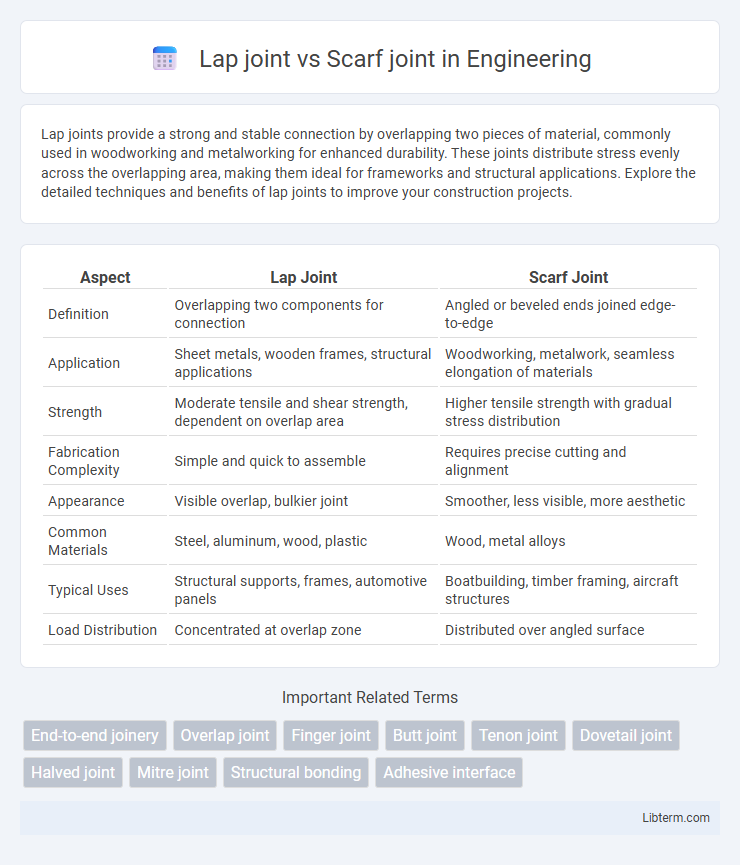

| Aspect | Lap Joint | Scarf Joint |

|---|---|---|

| Definition | Overlapping two components for connection | Angled or beveled ends joined edge-to-edge |

| Application | Sheet metals, wooden frames, structural applications | Woodworking, metalwork, seamless elongation of materials |

| Strength | Moderate tensile and shear strength, dependent on overlap area | Higher tensile strength with gradual stress distribution |

| Fabrication Complexity | Simple and quick to assemble | Requires precise cutting and alignment |

| Appearance | Visible overlap, bulkier joint | Smoother, less visible, more aesthetic |

| Common Materials | Steel, aluminum, wood, plastic | Wood, metal alloys |

| Typical Uses | Structural supports, frames, automotive panels | Boatbuilding, timber framing, aircraft structures |

| Load Distribution | Concentrated at overlap zone | Distributed over angled surface |

Introduction to Woodworking Joints

Lap joints and scarf joints are fundamental woodworking techniques used to join two pieces of wood securely. Lap joints involve overlapping two pieces and fastening them together, offering strength and simplicity ideal for frames and furniture. Scarf joints create a long, tapered connection by beveling the ends of two wood pieces, optimizing surface area for strong, seamless joints in extended wooden structures like beams and trims.

What Is a Lap Joint?

A lap joint is a type of woodworking or metalworking joint where two pieces overlap each other and are fastened together, providing increased surface area for bonding and enhanced structural strength. It is commonly used in frame construction, cabinetry, and shipbuilding due to its simplicity and ability to resist shear forces. Compared to a scarf joint, which joins pieces end-to-end with a tapered or angled cut, a lap joint offers greater mechanical stability by distributing loads across the overlapping sections.

What Is a Scarf Joint?

A scarf joint is a woodworking or metalworking technique used to join two pieces end-to-end by tapering or beveling their ends for increased surface area and strength. Unlike a lap joint where materials overlap, a scarf joint aligns the pieces flush, providing a smooth finish ideal for long beams or decorative applications. Its design improves load distribution and maintains structural integrity while minimizing visible seams.

Key Differences Between Lap and Scarf Joints

Lap joints overlap two pieces of material, providing strong shear resistance and ease of assembly, commonly used in woodworking and metal fabrication. Scarf joints taper the ends of two pieces to create a longer, smooth connection that enhances tensile strength and aesthetic appearance, often applied in fine carpentry and structural repairs. Lap joints are simpler and bulkier, while scarf joints require precise cutting and fitting for maximum strength and seamless integration.

Strength Comparison: Lap Joint vs Scarf Joint

Lap joints provide greater shear strength due to the increased overlapping area, making them ideal for applications requiring high load resistance. Scarf joints distribute stress more evenly along the bonded surfaces, enhancing tensile strength but generally offering less shear strength compared to lap joints. Choosing between these joints depends on the load type: lap joints excel under shear forces, while scarf joints perform better under tensile stresses.

Applications and Use Cases

Lap joints are commonly used in woodworking and metal fabrication for their strength and ease of assembly, making them ideal for frame construction, furniture, and structural supports. Scarf joints are preferred in applications requiring elongated components with smooth transitions, such as in boat building, musical instruments, and timber framing, where aesthetics and stress distribution are critical. The choice depends on whether shear strength or seamless appearance is prioritized in the final product.

Ease of Construction and Skill Level

Lap joints require basic woodworking skills and are easier to construct due to their simple overlapping design, making them ideal for beginners. Scarf joints demand higher precision and advanced skills, as they involve cutting angled or tapered edges that must fit tightly for structural integrity. The increased complexity of scarf joints generally results in longer construction time and greater tool proficiency compared to lap joints.

Material Efficiency and Waste

Lap joints typically offer greater material efficiency by overlapping two pieces of material, reducing the need for additional components or fasteners, which minimizes waste. Scarf joints involve beveling or tapering the ends of materials to create a longer bonded surface, often resulting in more precise cuts and reduced excess material. While lap joints can generate slight overlaps leading to potential waste, scarf joints are preferred in high-stress applications where maximizing material usage and minimizing waste is critical.

Aesthetic Considerations

Lap joints offer a clean, overlapping appearance that provides visible surface continuity but may create slight thickness variations at the joint, affecting the overall smoothness of the finished work. Scarf joints, known for their seamless, angled surfaces that align edges flush, yield a more refined and visually harmonious aesthetic, especially in fine woodworking or restorations where invisible joints are crucial. Selecting between lap and scarf joints depends on the desired visual effect, with scarf joints favored for elegant, uninterrupted grain patterns and lap joints preferred for robust, straightforward designs.

Choosing the Right Joint for Your Project

Choosing the right joint for your project depends on factors such as load direction, aesthetic preference, and material thickness. Lap joints provide strong, overlapping connections ideal for heavy loads and simple fabrication in woodworking and metalwork. Scarf joints create seamless, elongated joints suited for lengths requiring smooth surfaces and when maintaining material continuity is essential.

Lap joint Infographic

libterm.com

libterm.com