A slot weld is a type of weld made by joining two overlapping metal components through a slot or hole in one piece, allowing the weld to penetrate and fuse with the underlying component. This technique is commonly used for sheet metal fabrication, providing strong, concealed joints that enhance structural integrity without visible weld seams. Discover how slot welds can improve your metalworking projects in the detailed insights ahead.

Table of Comparison

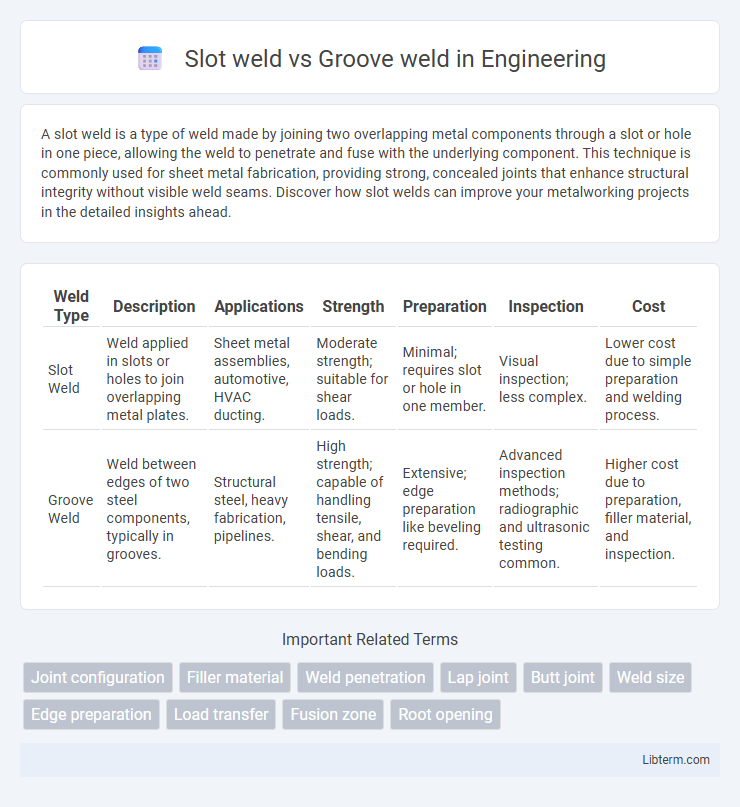

| Weld Type | Description | Applications | Strength | Preparation | Inspection | Cost |

|---|---|---|---|---|---|---|

| Slot Weld | Weld applied in slots or holes to join overlapping metal plates. | Sheet metal assemblies, automotive, HVAC ducting. | Moderate strength; suitable for shear loads. | Minimal; requires slot or hole in one member. | Visual inspection; less complex. | Lower cost due to simple preparation and welding process. |

| Groove Weld | Weld between edges of two steel components, typically in grooves. | Structural steel, heavy fabrication, pipelines. | High strength; capable of handling tensile, shear, and bending loads. | Extensive; edge preparation like beveling required. | Advanced inspection methods; radiographic and ultrasonic testing common. | Higher cost due to preparation, filler material, and inspection. |

Introduction to Slot Welds and Groove Welds

Slot welds join overlapping metal surfaces using a hole that allows the welding filler to fuse the materials, providing moderate strength primarily in sheet metal fabrication. Groove welds involve welding in the groove between two metal pieces, commonly used for butt joints to achieve strong, full-penetration welds suitable for structural applications. Each weld type offers specific advantages based on joint design, load requirements, and material thickness.

Definition and Characteristics of Slot Welds

Slot welds are a type of resistance weld made by fusing metal surfaces through a rectangular or elongated hole, creating a strong joint ideal for joining overlapping materials that cannot be clamped tightly together. Characterized by their use in sheet metal applications, slot welds provide a continuous weld profile that distributes stress evenly, offering high shear strength and resistance to fatigue. Unlike groove welds, which involve welding along a prepared groove between two members, slot welds focus on hidden joints beneath the surface, enhancing both structural integrity and aesthetic finish in assemblies.

Definition and Characteristics of Groove Welds

Groove welds are a type of weld where the edges of two metal pieces are prepared with a groove to allow for deeper penetration and stronger joint formation. These welds typically require edge preparation such as V-grooves, U-grooves, or J-grooves, which help in accommodating thicker materials and ensuring a more comprehensive fusion. Groove welds are commonly used for structural applications due to their ability to withstand high stress and load conditions.

Applications of Slot Welds in Industry

Slot welds are widely used in automotive and aerospace industries where joining overlapping metal sheets with limited access is essential for structural integrity. Their application in fabrication of heat exchangers and HVAC components allows efficient sealing and strength without the need for edge preparation, enhancing production speed. Slot welds provide superior resistance to shear loads, making them ideal for manufacturing heavy machinery and transportation equipment requiring durable metal-to-metal joints.

Common Uses of Groove Welds

Groove welds are commonly used in structural steel fabrication, pipeline welding, and pressure vessel construction due to their ability to provide deep penetration and strong joint integrity. They are ideal for joining thick materials or components that require high strength and durability, such as in bridges, building frameworks, and heavy machinery. Groove welds accommodate various joint configurations like butt, T-joints, and corner joints, making them versatile for many engineering and industrial applications.

Key Differences Between Slot Weld and Groove Weld

Slot welds involve joining two overlapping metal surfaces through a rectangular or oval hole, providing moderate strength primarily in shear applications, whereas groove welds create a fusion between edges of two plates with a shaped groove, offering superior strength and penetration. Slot welds are typically used for attaching components where accessibility is limited and joint alignment is less critical, while groove welds are preferred for structural applications requiring full penetration and high load-bearing capacity. The key differences lie in joint preparation, weld accessibility, strength requirements, and typical industrial applications.

Strength and Performance Comparison

Slot welds provide strong shear resistance by fusing overlapping parts through slots, making them ideal for lap joints and thin-sheet applications. Groove welds offer superior tensile strength and penetration by joining edges with a groove, commonly used for butt joints and thicker materials. Performance depends on load type, with groove welds generally outperforming slot welds in structural applications requiring high strength and fatigue resistance.

Advantages and Disadvantages of Slot Welds

Slot welds offer the advantage of providing strong, localized bonding between overlapping metal pieces without requiring edge preparation, making them efficient for joining thin sheets. They generally require less welding time and filler material compared to groove welds, reducing overall production costs. However, slot welds are limited by their size and are less effective for thicker materials or high-stress applications, where groove welds provide deeper penetration and stronger structural integrity.

Pros and Cons of Groove Welds

Groove welds provide strong, full-penetration joints ideal for structural applications requiring high strength and durability, with excellent adaptability to varying material thicknesses and joint configurations. They offer superior load-bearing capacity and stress distribution compared to slot welds but require more precise preparation and often incur higher labor and material costs. However, groove welds may involve increased risk of weld defects like incomplete fusion or porosity if not executed properly, impacting overall joint integrity.

Choosing the Right Weld Type for Your Project

Slot welds provide strong, concealed joints ideal for attaching overlapping components, especially in sheet metal fabrication, offering high shear strength with minimal surface distortion. Groove welds, including butt, V, and U types, are preferred for thicker materials where full penetration and structural integrity are critical, ensuring robust load-bearing capacity. Selecting between slot and groove welds depends on factors like material thickness, joint accessibility, stress conditions, and aesthetic requirements to optimize weld performance and project durability.

Slot weld Infographic

libterm.com

libterm.com