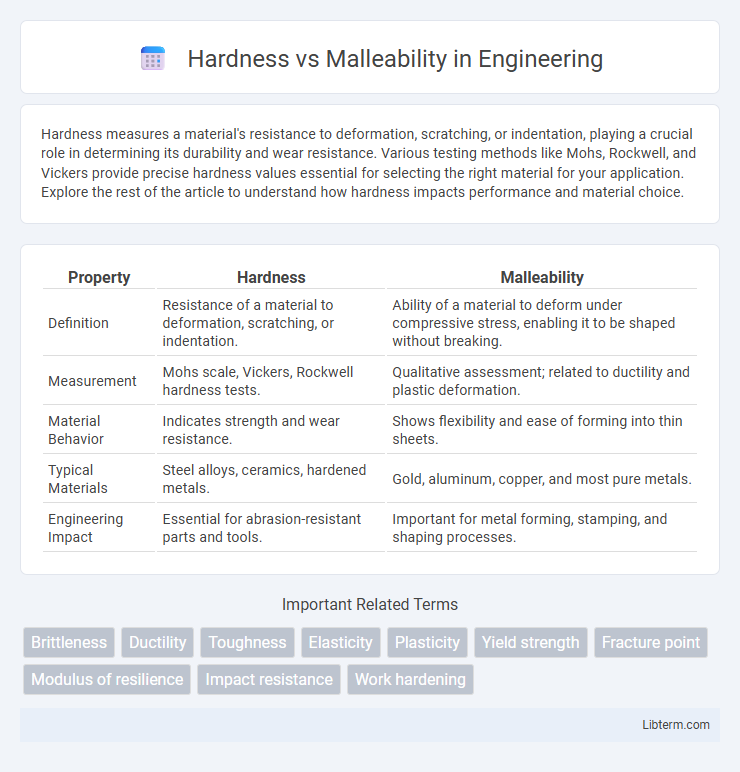

Hardness measures a material's resistance to deformation, scratching, or indentation, playing a crucial role in determining its durability and wear resistance. Various testing methods like Mohs, Rockwell, and Vickers provide precise hardness values essential for selecting the right material for your application. Explore the rest of the article to understand how hardness impacts performance and material choice.

Table of Comparison

| Property | Hardness | Malleability |

|---|---|---|

| Definition | Resistance of a material to deformation, scratching, or indentation. | Ability of a material to deform under compressive stress, enabling it to be shaped without breaking. |

| Measurement | Mohs scale, Vickers, Rockwell hardness tests. | Qualitative assessment; related to ductility and plastic deformation. |

| Material Behavior | Indicates strength and wear resistance. | Shows flexibility and ease of forming into thin sheets. |

| Typical Materials | Steel alloys, ceramics, hardened metals. | Gold, aluminum, copper, and most pure metals. |

| Engineering Impact | Essential for abrasion-resistant parts and tools. | Important for metal forming, stamping, and shaping processes. |

Defining Hardness and Malleability

Hardness measures a material's resistance to deformation, scratching, or penetration, often quantified by scales such as Mohs or Vickers. Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. These distinct properties reflect different mechanical behaviors crucial in material selection for manufacturing and engineering applications.

Key Differences Between Hardness and Malleability

Hardness measures a material's resistance to deformation or scratching, indicating durability against surface damage, while malleability refers to a material's ability to be deformed under compressive stress without cracking, such as being hammered or rolled into thin sheets. Key differences include that hardness is tested by methods like the Mohs scale and indentation tests, whereas malleability is observed through physical deformation processes. Metals like gold exhibit high malleability but low hardness, contrasting with materials like diamonds, which have high hardness but low malleability.

Factors Affecting Hardness in Materials

Hardness in materials is influenced by factors such as atomic bonding strength, crystal structure, and the presence of alloying elements or impurities that impede dislocation movement. Temperature and heat treatment processes also significantly affect hardness by altering microstructural features like grain size and phase distribution. Understanding these factors enables precise control over material properties for applications requiring specific hardness and wear resistance.

Factors Influencing Malleability

Malleability, the ability of a material to deform under compressive stress, is influenced by factors such as atomic structure, bonding type, and temperature. Metals with metallic bonding and a face-centered cubic (FCC) crystal structure, like gold and aluminum, exhibit high malleability due to the ease of dislocation movement. Higher temperatures increase atomic vibrations, reducing resistance to deformation and enhancing malleability.

Measurement Techniques for Hardness

Hardness measurement techniques include the Mohs scale, Rockwell hardness test, Vickers hardness test, and Brinell hardness test, each quantifying a material's resistance to indentation or scratching. The Rockwell test measures depth of penetration under a fixed load, providing quick and precise hardness values for metals, while Vickers uses a diamond pyramid indenter to evaluate hardness in thin materials or coatings. Brinell testing applies a steel or carbide ball to measure hardness in heterogeneous materials, and the Mohs scale ranks hardness based on scratch resistance with minerals from talc to diamond.

Testing and Assessing Malleability

Testing malleability involves assessing a material's ability to deform under compressive stress without cracking, commonly measured through hammering, rolling, or pressing techniques. Hardness tests, such as the Mohs scale or Vickers hardness test, quantify resistance to surface indentation and differ from malleability assessments that focus on ductile deformation properties. Accurate malleability evaluation is crucial in industries like metalworking, where materials must withstand shaping processes without fracturing.

Common Materials: Hardness vs Malleability Examples

Steel exhibits high hardness and moderate malleability, making it ideal for construction and manufacturing tools. Aluminum combines moderate hardness with excellent malleability, allowing it to be shaped into thin sheets for packaging and automotive parts. Copper shows lower hardness but superior malleability, facilitating its use in electrical wiring and intricate metalwork.

Industrial Applications: When to Prioritize Each Property

In industrial applications, hardness is prioritized for tools and components requiring wear resistance and durability, such as cutting blades, drill bits, and structural parts exposed to high stress. Malleability is favored when materials need to undergo significant deformation without breaking, making it essential for metal forming, stamping, and shaping processes in automotive and aerospace manufacturing. Selecting the appropriate balance between hardness and malleability enhances product performance and extends service life in specific industrial contexts.

How Alloying Impacts Hardness and Malleability

Alloying significantly influences hardness and malleability by altering the metal's internal structure and bonding characteristics. Elements such as carbon in steel increase hardness by forming carbides and impeding dislocation movement, while maintaining sufficient malleability for shaping processes. The balance between hardness and malleability depends on the type and concentration of alloying elements, controlling the metal's strength, ductility, and workability for specific industrial applications.

Choosing Materials: Balancing Hardness and Malleability

When choosing materials, balancing hardness and malleability is crucial for optimizing performance and durability. Hard materials resist deformation and wear, making them ideal for cutting tools and structural components, while malleable materials provide flexibility and ease of shaping, essential for forming processes and impact resistance. Engineers must evaluate the specific application requirements to select materials that offer the optimal trade-off between hardness for strength and malleability for workability.

Hardness Infographic

libterm.com

libterm.com