The pitch circle is a fundamental concept in gear design, representing an imaginary circle where teeth theoretically engage without slipping. Understanding the pitch circle diameter is crucial for ensuring proper meshing and smooth transmission of motion between gears. Explore the rest of the article to learn how pitch circle dimensions affect gear performance and your mechanical projects.

Table of Comparison

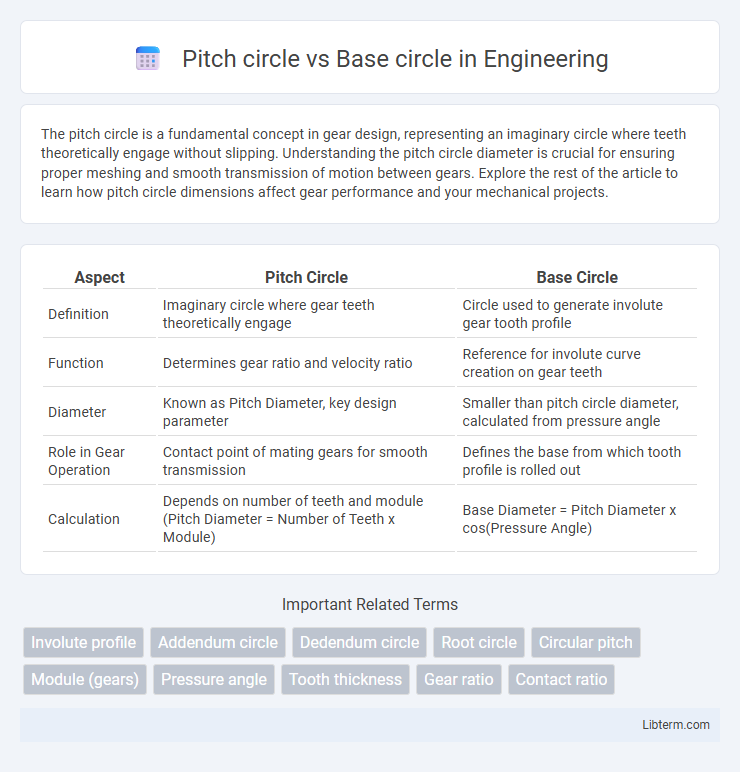

| Aspect | Pitch Circle | Base Circle |

|---|---|---|

| Definition | Imaginary circle where gear teeth theoretically engage | Circle used to generate involute gear tooth profile |

| Function | Determines gear ratio and velocity ratio | Reference for involute curve creation on gear teeth |

| Diameter | Known as Pitch Diameter, key design parameter | Smaller than pitch circle diameter, calculated from pressure angle |

| Role in Gear Operation | Contact point of mating gears for smooth transmission | Defines the base from which tooth profile is rolled out |

| Calculation | Depends on number of teeth and module (Pitch Diameter = Number of Teeth x Module) | Base Diameter = Pitch Diameter x cos(Pressure Angle) |

Introduction to Gear Circles

The pitch circle is an imaginary circle that represents the point of contact where two gears effectively transmit motion, serving as a fundamental reference in gear geometry. The base circle lies below the pitch circle and is crucial for generating the involute tooth profile, which ensures smooth gear engagement. Understanding the differences between the pitch circle and base circle is essential for analyzing gear kinematics and designing precise gear teeth.

Defining the Pitch Circle

The pitch circle is a fundamental concept in gear geometry, defined as the imaginary circle where the gears theoretically mesh without slipping, serving as the reference for gear dimensions and calculations. It determines the gear's size, pitch diameter, and is critical for calculating the gear ratio and tooth spacing. The base circle, smaller than the pitch circle, is the circle from which involute gear tooth profiles are generated, directly influencing the gear's tooth shape and smoothness of transmission.

Understanding the Base Circle

The base circle is a fundamental geometric feature in gear design from which the involute tooth profile is generated, serving as the starting point for tracing the involute curve that defines the gear tooth shape. Unlike the pitch circle, which represents the theoretical contact point for meshing gears and defines the gear ratio, the base circle lies closer to the gear center and is smaller in diameter. Understanding the base circle's role is crucial for accurate gear manufacturing and ensuring smooth, efficient power transmission in mechanical systems.

Key Differences: Pitch Circle vs Base Circle

Pitch circle is the theoretical circle where gear teeth engage, determining gear size and pitch diameter, while base circle is derived from the pitch circle using the pressure angle and serves as the reference for involute tooth profile generation. The pitch circle radius defines gear ratio and pitch line velocity, whereas the base circle radius influences the involute curve and tooth shape accuracy. Understanding these differences is crucial for precise gear design, ensuring smooth transmission and optimal performance.

Importance in Gear Design

Pitch circle and base circle are critical geometric references in gear design, determining the fundamental parameters for gear meshing and motion transfer. The pitch circle defines the theoretical point of contact where gears transmit power without slipping, while the base circle serves as the foundation for generating the involute tooth profile essential for smooth operation. Understanding the precise relationship between these circles ensures accurate gear ratio, load distribution, and minimizes wear, directly impacting gear efficiency and lifespan.

Mathematical Relationships

The pitch circle represents the theoretical circle on a gear where the teeth effectively engage, defined by the pitch diameter \( d = \frac{N}{P} \), where \( N \) is the number of teeth and \( P \) is the diametral pitch. The base circle diameter \( d_b \) is mathematically related to the pitch circle diameter \( d \) and the pressure angle \( \phi \) by the equation \( d_b = d \cos \phi \), serving as the foundation for involute tooth profiles. This geometric relationship ensures accurate calculation of gear tooth geometry, essential for proper meshing and transmission of motion.

Role in Gear Manufacturing

The pitch circle in gear manufacturing serves as the theoretical circle where gear teeth effectively engage, determining the gear's size and center distance, crucial for accurate meshing and power transmission. The base circle is fundamental for generating the involute tooth profile, as the gear tooth shape is derived from this circle to ensure smooth and efficient motion transfer. Precise definition and machining of both circles guarantee optimal gear performance, minimizing noise, wear, and operational inefficiencies.

Impact on Gear Performance

The pitch circle serves as the theoretical contact point where gear teeth mesh, directly influencing torque transmission and speed ratio accuracy. The base circle underlies the involute tooth profile, affecting the smoothness of gear engagement and minimizing frictional losses. Variations between the pitch circle and base circle dimensions significantly impact gear efficiency, noise generation, and wear patterns during operation.

Common Misconceptions

Pitch circle and base circle are often confused, but the pitch circle represents the theoretical circle where gears mesh perfectly and transmit motion without slip, while the base circle is fundamental in involute gear design, defining the starting point of the involute curve. A common misconception is that the pitch circle and base circle are the same or interchangeable, but the base circle is always smaller and critical for gear tooth profile generation. Understanding the distinct roles of these circles ensures accurate gear geometry and performance analysis in mechanical engineering.

Conclusion: Choosing the Right Reference Circle

Selecting the appropriate reference circle is crucial in gear design, with the pitch circle serving as the primary reference for defining gear size and mesh, while the base circle is essential for involute profile generation and accurate tooth engagement analysis. The pitch circle ensures correct gear ratio and smooth transmission, whereas the base circle provides the foundation for the involute curve, impacting contact stress and efficiency. Understanding the distinct roles of the pitch circle and base circle optimizes gear performance and longevity in mechanical systems.

Pitch circle Infographic

libterm.com

libterm.com