Surface integrity encompasses the condition of a material's surface after undergoing manufacturing processes, impacting its mechanical properties, corrosion resistance, and fatigue performance. Factors such as surface roughness, residual stresses, microstructure alterations, and contaminations play a crucial role in determining overall product durability and functionality. Explore the article to understand how optimizing surface integrity can enhance your components' performance and lifespan.

Table of Comparison

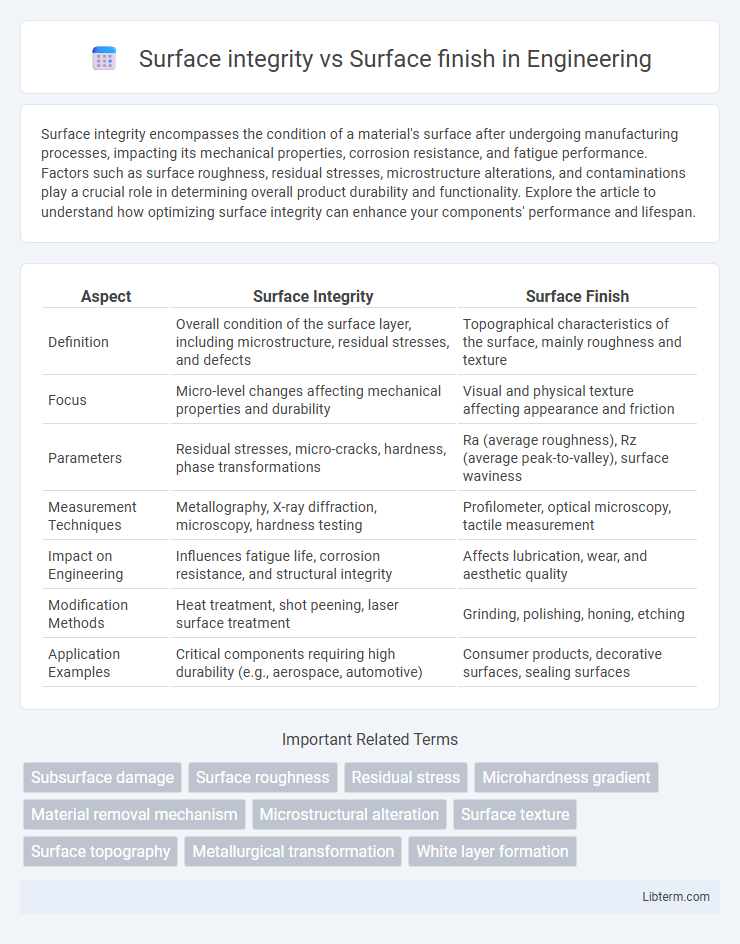

| Aspect | Surface Integrity | Surface Finish |

|---|---|---|

| Definition | Overall condition of the surface layer, including microstructure, residual stresses, and defects | Topographical characteristics of the surface, mainly roughness and texture |

| Focus | Micro-level changes affecting mechanical properties and durability | Visual and physical texture affecting appearance and friction |

| Parameters | Residual stresses, micro-cracks, hardness, phase transformations | Ra (average roughness), Rz (average peak-to-valley), surface waviness |

| Measurement Techniques | Metallography, X-ray diffraction, microscopy, hardness testing | Profilometer, optical microscopy, tactile measurement |

| Impact on Engineering | Influences fatigue life, corrosion resistance, and structural integrity | Affects lubrication, wear, and aesthetic quality |

| Modification Methods | Heat treatment, shot peening, laser surface treatment | Grinding, polishing, honing, etching |

| Application Examples | Critical components requiring high durability (e.g., aerospace, automotive) | Consumer products, decorative surfaces, sealing surfaces |

Understanding Surface Integrity and Surface Finish

Surface integrity encompasses the overall condition of a material's surface, including its microstructure, mechanical properties, and residual stresses, while surface finish specifically refers to the texture and smoothness measured by parameters like roughness (Ra). Understanding surface integrity involves analyzing factors such as subsurface deformation and potential defects that affect component performance and durability. Surface finish evaluation primarily focuses on visual and tactile quality, impacting aesthetics and friction behavior in applications.

Key Differences Between Surface Integrity and Surface Finish

Surface integrity encompasses the overall condition of a material's surface, including its mechanical, metallurgical, and chemical properties after a manufacturing process, whereas surface finish specifically refers to the topographical texture and roughness of the surface. Surface integrity affects the performance, durability, and resistance to fatigue and corrosion of the component, while surface finish primarily impacts aesthetic appearance and tactile smoothness. Key differences highlight that surface integrity addresses subsurface defects and material alterations, whereas surface finish is concerned with microscopic surface variations measurable through parameters like Ra and Rz.

Importance of Surface Integrity in Engineering Applications

Surface integrity encompasses the overall condition of a material's surface, including microstructure, residual stresses, and subsurface damage, which directly affects fatigue life, corrosion resistance, and wear performance. Surface finish refers to the texture and roughness of the topmost layer, influencing aesthetic appeal and friction behavior but not fully representing mechanical or chemical stability. In engineering applications, maintaining optimal surface integrity is crucial for ensuring component durability, reliability under cyclic loads, and resistance to environmental degradation, thereby extending service life and reducing maintenance costs.

Role of Surface Finish in Product Performance

Surface finish plays a critical role in product performance by affecting friction, wear resistance, and fatigue life. A smoother surface finish reduces stress concentrations and minimizes the risk of crack initiation, thereby enhancing durability and reliability. Optimizing surface finish directly improves functional efficiency and extends the service life of mechanical components.

Factors Affecting Surface Integrity

Surface integrity encompasses the overall condition of a machined surface, including its microstructure, residual stresses, and hardness, while surface finish primarily refers to the texture and roughness. Factors affecting surface integrity include cutting parameters such as speed, feed rate, and depth of cut, which influence heat generation and mechanical deformation during machining. Tool geometry, material properties, and cooling methods also play crucial roles in minimizing subsurface damage and preserving surface quality.

Parameters Used to Measure Surface Finish

Surface finish is primarily measured using parameters such as Ra (average roughness), Rz (average maximum height), and Rq (root mean square roughness), which quantify the microscopic texture of a machined surface. Surface integrity encompasses broader characteristics including surface finish, subsurface damage, microhardness, residual stresses, and metallurgical changes, reflecting the overall condition of the surface after machining. Accurate evaluation of surface finish parameters like Ra and Rz is essential for assessing the functional performance and aesthetic quality of manufactured components.

Effects of Manufacturing Processes on Surface Integrity

Manufacturing processes significantly affect surface integrity, which encompasses the surface finish, microstructural changes, residual stresses, and mechanical properties of the material. Processes like machining, grinding, and polishing influence surface finish by altering roughness and texture, while also inducing subsurface damage or phase transformations that impact durability and performance. Optimizing process parameters such as cutting speed, feed rate, and cooling methods enhances surface integrity by minimizing defects and improving functional characteristics of the workpiece.

Surface Finish Standards and Measurement Techniques

Surface finish standards such as ISO 4287 and ASME B46.1 define key parameters like Ra (average roughness) and Rz (average maximum height) that quantify surface texture. Measurement techniques including stylus profilometry, optical microscopy, and laser scanning provide precise surface profile data critical for ensuring compliance with these standards. Accurate assessment of surface finish influences the performance, wear resistance, and aesthetic qualities of manufactured components.

Impact of Surface Integrity and Finish on Component Lifespan

Surface integrity, encompassing subsurface microstructure and residual stresses, significantly affects the fatigue strength and corrosion resistance of components, thereby extending their lifespan beyond the visual quality indicated by surface finish alone. Surface finish, primarily concerned with roughness parameters like Ra and Rz, influences initial wear and friction but does not fully capture the deeper impacts of microcracks or residual tensile stresses on durability. Optimizing both surface integrity and finish is critical in high-performance engineering applications to prevent premature failure and enhance operational reliability.

Optimizing Both Surface Integrity and Surface Finish for Superior Quality

Optimizing both surface integrity and surface finish is critical for enhancing the performance and longevity of machined components. Surface integrity encompasses subsurface properties such as microhardness, residual stresses, and microstructural changes, while surface finish relates to the topographical texture and roughness measured by parameters like Ra and Rz. Advanced machining techniques and process parameters must be precisely controlled to achieve a balance that minimizes surface defects and improves fatigue resistance, wear performance, and corrosion resistance, ultimately ensuring superior product quality.

Surface integrity Infographic

libterm.com

libterm.com