Forging is a manufacturing process that shapes metal using compressive forces, enhancing its strength and durability by refining its internal grain structure. Various techniques such as open-die, closed-die, and impression-die forging allow for different levels of precision and complexity in metal components. Explore the rest of this article to understand how forging can improve your production quality and efficiency.

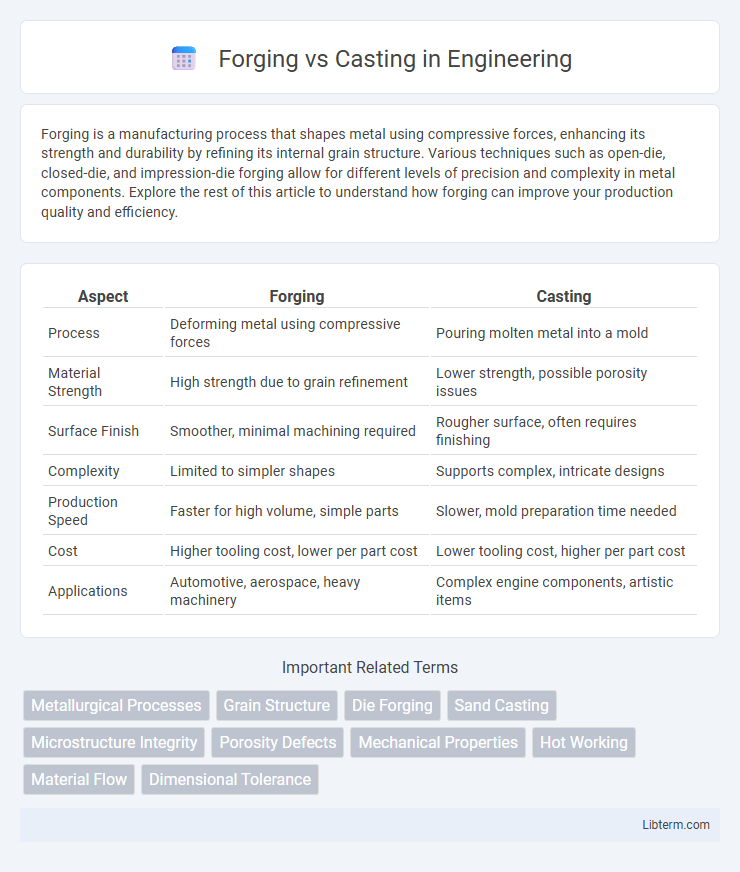

Table of Comparison

| Aspect | Forging | Casting |

|---|---|---|

| Process | Deforming metal using compressive forces | Pouring molten metal into a mold |

| Material Strength | High strength due to grain refinement | Lower strength, possible porosity issues |

| Surface Finish | Smoother, minimal machining required | Rougher surface, often requires finishing |

| Complexity | Limited to simpler shapes | Supports complex, intricate designs |

| Production Speed | Faster for high volume, simple parts | Slower, mold preparation time needed |

| Cost | Higher tooling cost, lower per part cost | Lower tooling cost, higher per part cost |

| Applications | Automotive, aerospace, heavy machinery | Complex engine components, artistic items |

Introduction to Forging and Casting

Forging is a manufacturing process where metal is shaped by applying compressive forces, often using a hammer or press, resulting in improved mechanical properties such as strength and grain structure. Casting involves pouring molten metal into a mold to solidify into a desired shape, allowing for complex geometries and large components. Both techniques serve distinct purposes in manufacturing, with forging offering superior durability and casting enabling detailed designs.

Definitions and Core Differences

Forging is a metalworking process involving shaping metal using compressive forces, typically performed while the metal is heated but solid, enhancing its grain structure and mechanical properties. Casting involves pouring molten metal into a mold where it solidifies into the desired shape, allowing complex geometries but often resulting in less uniform material properties. The core difference lies in forging producing stronger, more durable components with refined microstructures, while casting offers greater design flexibility at the expense of potential porosity and structural inconsistencies.

The Forging Process Explained

The forging process involves shaping metal using compressive forces, typically performed with a hammer or press, to enhance the material's grain structure and mechanical properties. This method produces parts with superior strength, fatigue resistance, and toughness compared to casting, where molten metal is poured into molds. Forging is ideal for critical components in aerospace, automotive, and industrial applications that require high reliability and performance.

The Casting Process Explained

The casting process involves pouring molten metal into a pre-shaped mold where it solidifies into the desired form, allowing for complex geometries and internal cavities unachievable by forging. Key stages include pattern making, mold preparation, pouring, cooling, and cleaning, ensuring precision in shape and size while minimizing material waste. Casting is ideal for mass production of intricate parts but generally produces components with lower strength and toughness compared to forged parts.

Material Properties: Forging vs Casting

Forging produces materials with superior mechanical properties such as higher tensile strength, improved grain structure, and enhanced fatigue resistance due to the controlled deformation process. Casting, while allowing complex shapes to be created, often results in materials with lower strength and increased porosity, leading to reduced durability. Forged components generally exhibit better impact toughness and resistance to wear compared to cast parts, making them ideal for high-stress applications.

Strength and Durability Comparison

Forging produces components with superior strength and durability due to the aligned grain structure formed during the deformation process, which enhances fatigue resistance and impact toughness. Casting often results in coarser microstructures and potential porosity, leading to lower mechanical strength and reduced wear resistance compared to forged parts. Consequently, forged components are preferred in high-stress applications requiring enhanced mechanical performance and longevity.

Cost Implications of Forging and Casting

Forging generally involves higher initial tooling and equipment costs due to the need for robust dies and presses but offers lower per-unit costs for large production runs because of faster cycle times and less material waste. Casting typically has lower upfront tooling expenses, making it cost-effective for small batches and complex shapes; however, higher post-processing and longer production cycles can increase overall costs with scale. Choosing between forging and casting depends on factors like production volume, material usage, and the complexity of the component, influencing long-term cost efficiency.

Applications and Industry Uses

Forging is extensively used in automotive, aerospace, and heavy machinery industries due to its superior strength and fatigue resistance, making it ideal for critical components like crankshafts, gears, and turbine blades. Casting dominates in manufacturing complex shapes and large-scale production for industries such as construction, plumbing, and automotive, where components like engine blocks, valves, and pipe fittings require intricate geometries. The choice between forging and casting depends on application demands, with forging preferred for high-stress parts and casting favored for cost-effective production of detailed, low-stress components.

Advantages and Disadvantages of Each Method

Forging offers superior mechanical properties such as increased strength, toughness, and fatigue resistance due to its grain refinement and directional alignment benefits, making it ideal for high-stress components; however, it has higher tooling costs and is limited in producing complex shapes. Casting enables the creation of complex geometries and large parts with lower initial costs and minimal material waste, but it often results in porosity, shrinkage defects, and lower mechanical strength compared to forged parts. Both methods require careful consideration of application requirements to balance performance, cost, and design flexibility.

Choosing the Right Method: Key Considerations

Selecting between forging and casting depends on factors such as mechanical strength, dimensional accuracy, and production costs. Forging offers superior strength and toughness due to grain refinement, making it ideal for high-stress components, while casting provides design flexibility and cost efficiency for complex geometries. Assessing project requirements including material properties, volume, and tolerance levels ensures the optimal manufacturing method is chosen.

Forging Infographic

libterm.com

libterm.com