Painting enhances any space by adding color, texture, and personality to your environment. Utilizing various techniques and quality materials ensures a lasting and visually appealing finish. Explore the rest of the article to discover expert tips and creative ideas for your next painting project.

Table of Comparison

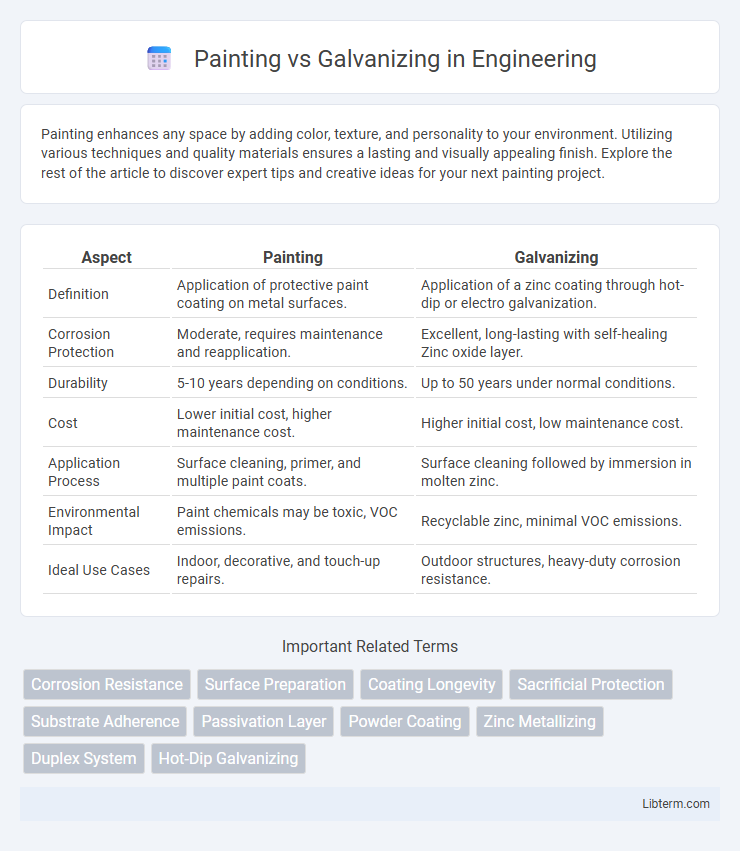

| Aspect | Painting | Galvanizing |

|---|---|---|

| Definition | Application of protective paint coating on metal surfaces. | Application of a zinc coating through hot-dip or electro galvanization. |

| Corrosion Protection | Moderate, requires maintenance and reapplication. | Excellent, long-lasting with self-healing Zinc oxide layer. |

| Durability | 5-10 years depending on conditions. | Up to 50 years under normal conditions. |

| Cost | Lower initial cost, higher maintenance cost. | Higher initial cost, low maintenance cost. |

| Application Process | Surface cleaning, primer, and multiple paint coats. | Surface cleaning followed by immersion in molten zinc. |

| Environmental Impact | Paint chemicals may be toxic, VOC emissions. | Recyclable zinc, minimal VOC emissions. |

| Ideal Use Cases | Indoor, decorative, and touch-up repairs. | Outdoor structures, heavy-duty corrosion resistance. |

Introduction to Painting and Galvanizing

Painting involves applying a protective or decorative coating of pigment suspended in a liquid medium directly onto a metal surface, enhancing corrosion resistance and aesthetic appeal. Galvanizing consists of coating metal, primarily steel or iron, with a layer of zinc through hot-dip or electro-galvanizing processes to create a durable, corrosion-resistant barrier. Both methods serve as essential treatments in metal preservation, with painting providing customizable colors and galvanizing offering long-lasting rust prevention.

Definition and Process of Painting

Painting involves applying a protective or decorative coating of liquid pigments onto a surface, creating a barrier against environmental factors like moisture and corrosion. The process of painting includes surface preparation such as cleaning and sanding, followed by priming to enhance adhesion, then applying one or more layers of paint using brushes, rollers, or spray equipment, and finally allowing adequate drying time between coats. This method provides versatility in color and texture but requires maintenance to ensure long-term protection compared to galvanizing, which involves coating metal with a layer of zinc for corrosion resistance.

Definition and Process of Galvanizing

Galvanizing is a coating process that involves applying a protective layer of zinc to steel or iron to prevent rust and corrosion, typically through hot-dip galvanizing where the metal is submerged in molten zinc. This method creates a durable, long-lasting barrier that corrodes preferentially, protecting the underlying metal. Painting, by contrast, involves applying layers of paint to create a protective and decorative finish but lacks the metallurgical bond and corrosion resistance inherent in galvanized coatings.

Durability: Painted vs Galvanized Surfaces

Galvanized surfaces exhibit superior durability compared to painted ones due to their zinc coating that provides long-lasting corrosion resistance, especially in harsh environments. Painted surfaces offer aesthetic flexibility but often require more frequent maintenance and repainting to prevent rust and degradation. For industrial applications exposed to moisture and chemicals, galvanizing ensures extended lifespan and reduced maintenance costs, outperforming traditional paint protection.

Corrosion Resistance Comparison

Galvanizing provides superior corrosion resistance by forming a robust zinc coating that sacrificially protects the underlying steel from rust and environmental damage. Painting offers a protective barrier that can prevent moisture and oxygen from reaching the metal but requires regular maintenance and repainting to ensure long-term effectiveness. In highly corrosive environments, galvanized steel outperforms painted surfaces due to its self-healing properties and durability under abrasive conditions.

Cost Analysis: Painting vs Galvanizing

Painting generally incurs lower upfront costs compared to galvanizing, with average expenses ranging from $0.50 to $3 per square foot, depending on paint type and application method. Galvanizing involves higher initial investment, typically between $1.50 and $4 per square foot, due to the hot-dip process and material requirements but offers longer-term cost benefits by reducing maintenance and repainting frequency. Over the lifespan of steel structures, galvanizing often proves more cost-effective by minimizing corrosion-related repairs and extending service life.

Maintenance Requirements and Lifespan

Painting requires regular maintenance such as surface cleaning, sanding, and repainting every 3 to 7 years to prevent corrosion and maintain appearance. Galvanizing offers a longer lifespan, often exceeding 50 years, with minimal maintenance due to its robust zinc coating that protects steel from rust. The durability of galvanizing reduces long-term maintenance costs compared to painting, making it ideal for harsh environments.

Environmental Impact and Sustainability

Painting often involves the use of volatile organic compounds (VOCs) and hazardous chemicals that can contribute to air pollution and require frequent maintenance, increasing environmental burden over time. Galvanizing, particularly hot-dip galvanizing, provides a longer-lasting protective zinc coating that reduces the need for reapplications and minimizes waste generation. Zinc coatings are recyclable and have a lower life-cycle environmental footprint, making galvanizing a more sustainable option for corrosion protection in industrial applications.

Common Applications for Each Method

Painting is commonly applied in industries such as automotive, construction, and household appliances to provide decorative finishes and corrosion protection on steel and iron surfaces. Galvanizing is predominantly used in infrastructure projects, including bridges, highways, and outdoor handrails, due to its superior rust resistance and durability in harsh environmental conditions. Both methods protect metal but serve different functional and aesthetic purposes based on application demands and environmental exposure.

Choosing the Right Protection Method

Selecting between painting and galvanizing depends on environmental conditions, budget, and desired durability for metal protection. Galvanizing applies a zinc coating providing superior corrosion resistance, especially in harsh outdoor or marine environments, with low maintenance requirements. Painting offers aesthetic versatility and is suitable for less aggressive conditions, but may require frequent reapplication to maintain protection.

Painting Infographic

libterm.com

libterm.com