Emulsification is the process of mixing two immiscible liquids, such as oil and water, to create a stable blend called an emulsion. This technique is essential in various industries, including food production, cosmetics, and pharmaceuticals, ensuring consistent texture and improved product performance. Discover how emulsification can enhance your products by reading the rest of the article.

Table of Comparison

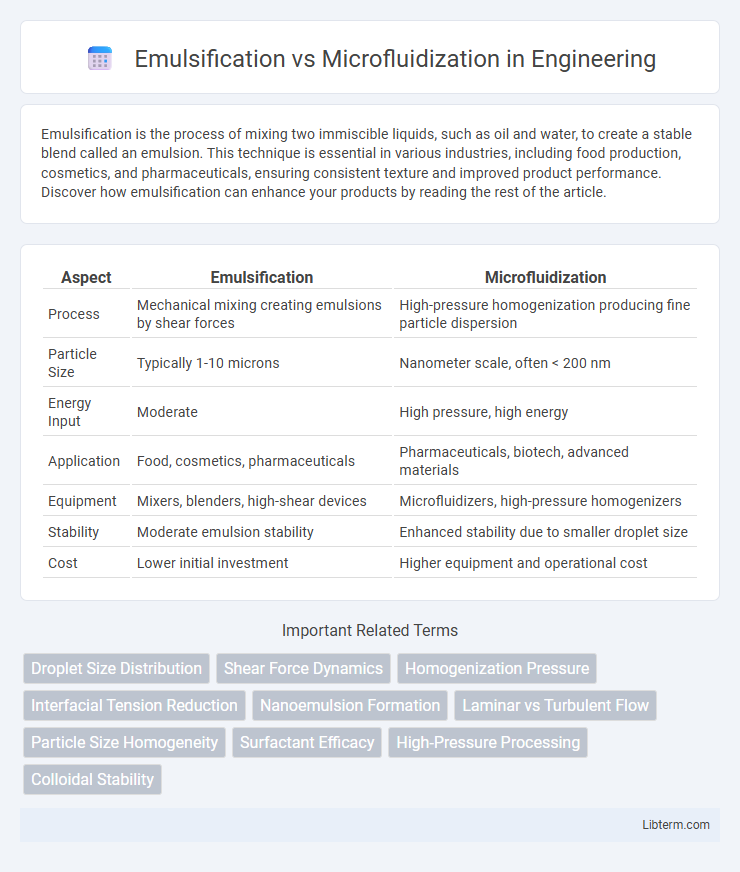

| Aspect | Emulsification | Microfluidization |

|---|---|---|

| Process | Mechanical mixing creating emulsions by shear forces | High-pressure homogenization producing fine particle dispersion |

| Particle Size | Typically 1-10 microns | Nanometer scale, often < 200 nm |

| Energy Input | Moderate | High pressure, high energy |

| Application | Food, cosmetics, pharmaceuticals | Pharmaceuticals, biotech, advanced materials |

| Equipment | Mixers, blenders, high-shear devices | Microfluidizers, high-pressure homogenizers |

| Stability | Moderate emulsion stability | Enhanced stability due to smaller droplet size |

| Cost | Lower initial investment | Higher equipment and operational cost |

Introduction to Emulsification and Microfluidization

Emulsification is a process that combines two immiscible liquids, such as oil and water, into a stable mixture by creating fine droplets, commonly used in pharmaceuticals, food, and cosmetics. Microfluidization is an advanced emulsification technique employing high-pressure homogenization through microchannels to produce uniform and ultra-fine emulsions with improved stability and bioavailability. Both methods enhance product consistency, but microfluidization offers superior control over droplet size distribution and scalability for industrial applications.

Basic Principles of Emulsification

Emulsification involves the dispersion of one liquid into another immiscible liquid, typically oil in water or water in oil, by applying mechanical shear forces to create droplets stabilized by surfactants. Microfluidization is a high-pressure homogenization technique that forces fluids through microchannels, generating intense shear, turbulence, and impact to produce uniform and smaller emulsion droplets. Basic principles of emulsification rely on reducing interfacial tension and utilizing energy input to overcome droplet coalescence, with microfluidization providing superior control over droplet size distribution compared to traditional emulsification methods.

How Microfluidization Works

Microfluidization works by forcing fluids through microscopic channels at extremely high pressure, creating intense shear and impact forces that break down particles into uniform, nanoscale droplets, enhancing product stability and texture. This process generates a fine emulsion with superior droplet size distribution compared to traditional emulsification methods, improving bioavailability and shelf life. The technology is widely used in pharmaceuticals, food, and cosmetics for producing consistent, high-quality emulsions with enhanced performance characteristics.

Key Differences Between Emulsification and Microfluidization

Emulsification typically involves blending two immiscible liquids using mechanical stirring or high-shear mixers to create a stable mixture, often resulting in larger droplet sizes. Microfluidization uses high-pressure homogenization, forcing liquids through microchannels to produce uniform, ultra-fine droplets with improved stability and enhanced bioavailability. Key differences include droplet size distribution, energy input, and scalability, with microfluidization offering superior particle uniformity and often better performance in pharmaceutical and food applications.

Equipment Used in Emulsification vs Microfluidization

Emulsification typically employs high-shear mixers, rotor-stator systems, or ultrasonic emulsifiers designed to break down droplets and create stable emulsions. Microfluidization uses specialized microfluidizers that force fluids through microchannels at high pressures, producing uniform nanoemulsions with improved stability and particle size control. The microfluidization equipment offers precise pressure and flow rate control, enabling finer emulsification compared to conventional emulsifiers.

Applications in Food and Beverage Industry

Emulsification and microfluidization are critical techniques in the food and beverage industry for creating stable mixtures of immiscible liquids, enhancing texture, and improving product quality. Emulsification is widely used in salad dressings, sauces, and dairy products to achieve uniform dispersion, while microfluidization, with its high-pressure homogenization, produces finer emulsions critical for beverages like juice blends and functional drinks, enhancing bioavailability and shelf life. Microfluidization also supports the development of nanoemulsions, advancing nutrient delivery and sensory attributes in functional foods and nutraceuticals.

Benefits of Microfluidization Over Traditional Emulsification

Microfluidization offers superior particle size reduction and uniform droplet distribution compared to traditional emulsification, resulting in enhanced stability and improved bioavailability of emulsions. This technology achieves higher shear forces through precise high-pressure homogenization, enabling the production of nanoemulsions with consistent texture and superior shelf life. Consequently, microfluidization is preferred in pharmaceutical, cosmetic, and food industries for its ability to create more stable and effective products.

Challenges and Limitations of Both Techniques

Emulsification faces challenges in achieving uniform droplet size distribution and often requires high energy input, leading to heat generation that can degrade sensitive ingredients. Microfluidization offers finer droplet size and enhanced stability but is limited by high operational costs and complex maintenance requirements. Both techniques struggle with scalability issues for industrial production, making process optimization critical to balance efficiency and product quality.

Industrial Trends in Emulsification Technologies

Industrial trends in emulsification technologies prioritize microfluidization for its ability to produce smaller, uniform droplet sizes, enhancing stability and bioavailability in food, pharmaceutical, and cosmetic products. Emulsification methods are evolving toward high-shear and high-pressure techniques like microfluidization to meet demands for energy efficiency and scalability in large-scale production. Advances in microfluidization equipment enable precise control over particle size distribution, making it a leading choice for industries seeking improved product performance and consistency.

Choosing the Right Method for Your Application

Emulsification is ideal for applications requiring coarse to medium droplet sizes, offering cost-effective and scalable solutions for food, cosmetics, and pharmaceuticals. Microfluidization provides ultra-fine emulsions with superior stability and uniformity, essential for high-performance pharmaceuticals and advanced material formulations. Selecting the right method depends on droplet size requirements, product stability, production scale, and budget constraints.

Emulsification Infographic

libterm.com

libterm.com