Spur gears are the simplest type of gear, featuring straight teeth mounted on a parallel shaft, making them highly efficient for transmitting motion and power in various mechanical systems. Their design ensures minimal power loss and easy manufacturing, making them ideal for applications requiring precise speed and torque control. Explore this article to discover how spur gears can enhance Your mechanical projects and improve system performance.

Table of Comparison

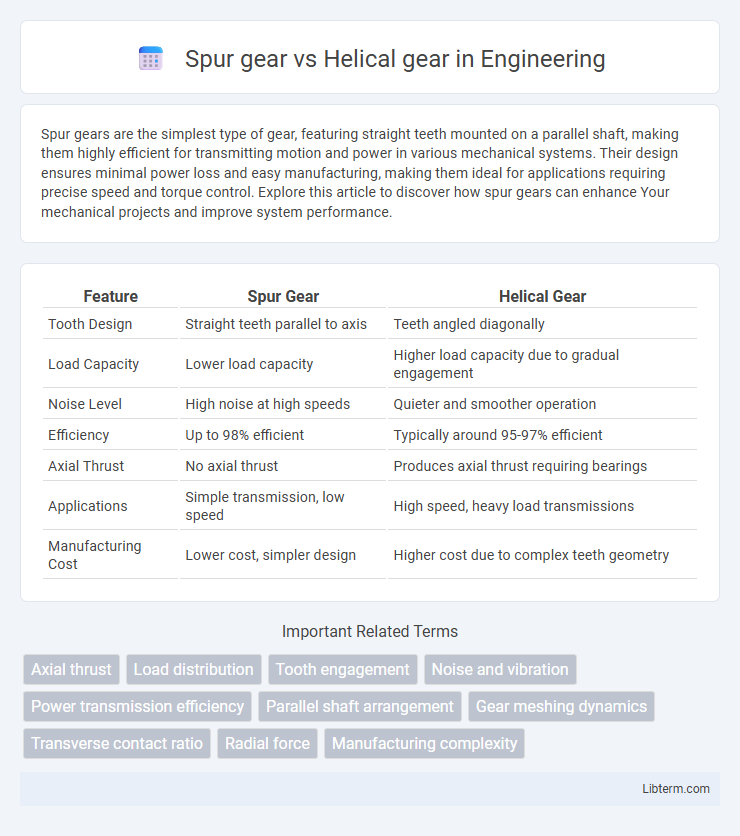

| Feature | Spur Gear | Helical Gear |

|---|---|---|

| Tooth Design | Straight teeth parallel to axis | Teeth angled diagonally |

| Load Capacity | Lower load capacity | Higher load capacity due to gradual engagement |

| Noise Level | High noise at high speeds | Quieter and smoother operation |

| Efficiency | Up to 98% efficient | Typically around 95-97% efficient |

| Axial Thrust | No axial thrust | Produces axial thrust requiring bearings |

| Applications | Simple transmission, low speed | High speed, heavy load transmissions |

| Manufacturing Cost | Lower cost, simpler design | Higher cost due to complex teeth geometry |

Introduction to Spur and Helical Gears

Spur gears feature straight teeth parallel to the gear axis, providing efficient power transmission with minimal axial thrust, making them ideal for low to moderate speeds. Helical gears have teeth cut at an angle, creating a gradual engagement that reduces noise and vibration while enabling higher load capacity and smoother operation. Commonly used in automotive transmissions and industrial machinery, helical gears offer improved performance over spur gears in high-speed and heavy-load applications.

Fundamental Differences Between Spur and Helical Gears

Spur gears feature straight teeth parallel to the gear axis, resulting in simpler manufacturing and efficient power transmission at moderate speeds. Helical gears have angled teeth that engage gradually, providing smoother and quieter operation with higher load capacity and better alignment tolerance. The primary distinction lies in the tooth orientation, influencing noise level, durability, and application suitability in mechanical systems.

Design and Structural Characteristics

Spur gears feature straight teeth parallel to the gear axis, resulting in a simpler design that facilitates easier manufacturing and assembly, ideal for low-speed applications. Helical gears have teeth cut at an angle to the axis, creating a gradual engagement that reduces noise and vibration while providing higher load capacity and smoother operation. The angled teeth of helical gears induce axial thrust, requiring bearings to absorb these forces, whereas spur gears produce radial forces along the gear teeth.

Efficiency Comparison: Spur vs Helical Gears

Spur gears typically exhibit higher efficiency, often around 98-99%, due to their simpler design and lower friction losses. Helical gears, while offering smoother and quieter operation, usually have slightly lower efficiency, ranging between 94-98%, caused by increased sliding contact and resulting friction. The efficiency difference is crucial in high-speed or power-sensitive applications where minimizing energy loss is essential.

Load Capacity and Torque Transmission

Helical gears offer higher load capacity compared to spur gears due to their angled teeth, which engage gradually and distribute stress more evenly across the gear face. This design also allows helical gears to transmit greater torque with reduced noise and vibration, enhancing efficiency and durability in high-load applications. Spur gears typically have lower torque transmission capabilities and are better suited for low to moderate load scenarios where simplicity and cost-effectiveness are prioritized.

Noise and Vibration Performance

Spur gears generate higher noise and vibration levels due to their straight teeth that engage abruptly, causing impact loads during meshing. Helical gears operate more smoothly with angled teeth that engage gradually, significantly reducing noise and vibration in high-speed applications. Their superior performance in noise and vibration control makes helical gears preferable for environments requiring quiet and efficient power transmission.

Applications in Industry

Spur gears are commonly used in conveyor systems, simple machinery, and automotive transmissions where low speed and moderate torque are required due to their straightforward design and easy manufacturing. Helical gears are preferred in high-speed applications such as elevators, printing presses, and automotive gearboxes because their angled teeth provide smoother and quieter operation with higher load capacity. Industries that demand efficiency and noise reduction, like aerospace and robotics, frequently select helical gears for precision motion control and durability.

Maintenance and Durability Factors

Spur gears require less maintenance due to their simpler design but tend to experience higher noise and stress, impacting durability under heavy loads. Helical gears offer smoother operation and better load distribution, resulting in enhanced durability and longer service life, though they demand more precise alignment and lubrication for optimal performance. Proper lubrication and alignment are critical for extending the lifespan and minimizing wear in both gear types.

Cost Analysis and Economic Considerations

Spur gears generally have lower manufacturing costs due to simpler design and ease of production, making them more economical for low to moderate-speed applications. Helical gears, with their angled teeth and improved load distribution, incur higher manufacturing expenses but offer better efficiency and quieter operation, which can reduce maintenance and operational costs over time. Economic considerations often weigh the upfront cost against long-term benefits such as durability, noise reduction, and energy savings, with helical gears favored in high-speed or high-load scenarios despite the initial premium.

Choosing the Right Gear: Key Decision Factors

Selecting between spur and helical gears hinges on factors such as load capacity, noise level, and efficiency. Spur gears offer simplicity and high efficiency for low-speed applications with moderate loads, making them ideal for straightforward power transmission. Helical gears excel in high-speed and high-load environments by providing smoother operation and reduced noise due to their angled teeth, making them suitable for automotive transmissions and industrial machinery.

Spur gear Infographic

libterm.com

libterm.com