Laminar flow describes the smooth, orderly movement of fluid in parallel layers with minimal disruption between them, commonly observed in low-velocity or highly viscous fluids. This flow regime is essential for reducing drag and improving efficiency in various engineering applications, including aerodynamics and fluid transport systems. Explore the detailed insights in the rest of this article to understand how laminar flow impacts your projects and designs.

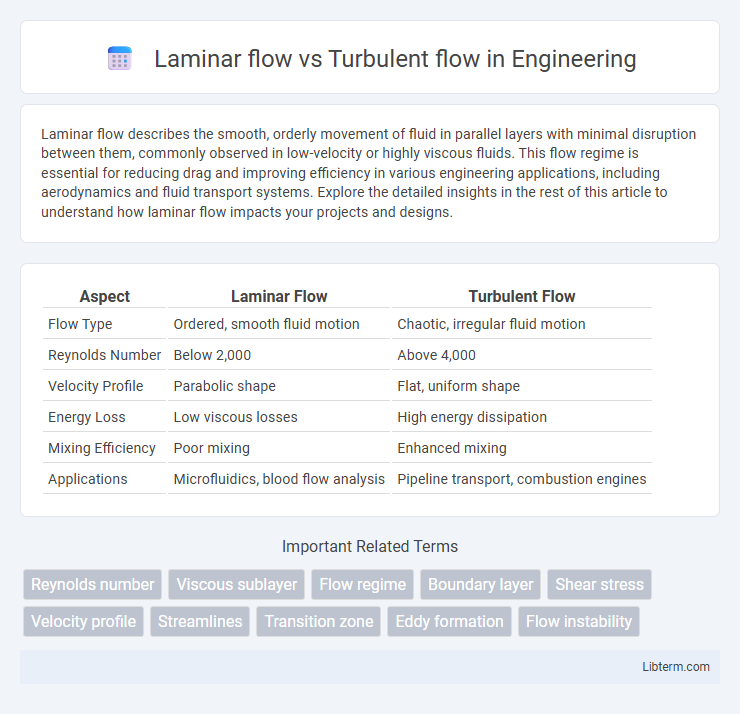

Table of Comparison

| Aspect | Laminar Flow | Turbulent Flow |

|---|---|---|

| Flow Type | Ordered, smooth fluid motion | Chaotic, irregular fluid motion |

| Reynolds Number | Below 2,000 | Above 4,000 |

| Velocity Profile | Parabolic shape | Flat, uniform shape |

| Energy Loss | Low viscous losses | High energy dissipation |

| Mixing Efficiency | Poor mixing | Enhanced mixing |

| Applications | Microfluidics, blood flow analysis | Pipeline transport, combustion engines |

Introduction to Fluid Flow Dynamics

Laminar flow occurs when fluid particles move in parallel layers with minimal mixing, characterized by low Reynolds numbers typically below 2,300. Turbulent flow features chaotic eddies and vortices, arising at higher Reynolds numbers usually above 4,000, leading to increased momentum and energy transfer within the fluid. Understanding the distinction between laminar and turbulent flow is essential for analyzing fluid dynamics in engineering applications such as pipeline design, aerodynamic optimization, and heat transfer processes.

Defining Laminar Flow

Laminar flow is characterized by smooth, parallel layers of fluid that move in an orderly fashion with minimal mixing between layers, ensuring low velocity and steady fluid motion. This type of flow typically occurs at low Reynolds numbers, usually below 2,000, where viscous forces dominate inertial forces. In contrast, turbulent flow features chaotic fluid movement with eddies and vortices, resulting in enhanced mixing and higher flow resistance.

Characteristics of Laminar Flow

Laminar flow is characterized by smooth, parallel layers of fluid moving in an orderly manner with minimal mixing and low Reynolds numbers (typically below 2000). This flow type exhibits steady velocity profiles and low momentum diffusion, resulting in reduced frictional losses and predictable fluid behavior. It is commonly observed in applications involving viscous fluids and slow flow rates, such as microfluidics and blood circulation in small vessels.

Defining Turbulent Flow

Turbulent flow is characterized by chaotic, irregular fluid motion with eddies and vortices causing rapid fluctuations in velocity and pressure. It occurs at high Reynolds numbers where inertial forces dominate over viscous forces, leading to increased mixing and energy dissipation. Unlike laminar flow, turbulent flow enhances heat and mass transfer but increases drag and resistance in fluid systems.

Characteristics of Turbulent Flow

Turbulent flow is characterized by chaotic fluid motion with irregular fluctuations and eddies, leading to high mixing rates and enhanced momentum transfer. It occurs at high Reynolds numbers, typically above 4000, where inertial forces dominate viscous forces. This flow regime exhibits increased energy dissipation and greater frictional losses compared to laminar flow.

Key Differences Between Laminar and Turbulent Flow

Laminar flow is characterized by smooth, orderly fluid motion with parallel layers and low Reynolds numbers typically below 2,000, resulting in minimal mixing and friction. Turbulent flow involves chaotic, irregular fluid movement with high Reynolds numbers usually above 4,000, causing increased mixing, momentum transfer, and energy dissipation. Key differences include velocity profile shape, pressure drop, and flow stability, impacting engineering applications such as pipeline design and aerodynamic efficiency.

Factors Influencing Flow Regimes

Flow regimes in fluid dynamics are primarily influenced by factors such as fluid velocity, viscosity, and characteristic length, which collectively determine the Reynolds number, a critical dimensionless parameter. Low Reynolds numbers indicate laminar flow characterized by smooth, orderly fluid motion, while high Reynolds numbers correspond to turbulent flow exhibiting chaotic and irregular fluctuations. Surface roughness and flow geometry also significantly affect the transition between laminar and turbulent regimes, impacting flow stability and energy loss in fluid systems.

Real-World Examples and Applications

Laminar flow, characterized by smooth, orderly fluid motion, is commonly observed in medical applications such as intravenous drip systems and in aerospace engineering for reducing drag on aircraft wings. Turbulent flow, marked by chaotic and irregular fluid movement, occurs in natural settings like river rapids and in industrial processes such as pipeline transportation of oil and gas, where enhanced mixing is beneficial. Understanding the distinctions between laminar and turbulent flow is crucial for optimizing designs in HVAC systems, automotive engines, and chemical reactors to improve efficiency and performance.

Impacts on Engineering and Design

Laminar flow, characterized by smooth and orderly fluid motion, reduces frictional losses and enhances predictability in engineering systems, making it ideal for precise applications such as microfluidics and aerodynamic design. Turbulent flow, with its chaotic and irregular velocity fluctuations, increases mixing and heat transfer rates but also causes higher pressure drops and structural vibrations, challenging engineers to design strong, durable, and efficient components. Understanding the transition between laminar and turbulent regimes is crucial for optimizing performance, energy consumption, and safety in pipelines, HVAC systems, and aerospace engineering.

Conclusion: Choosing the Right Flow Type

Laminar flow ensures smooth, predictable fluid movement ideal for applications requiring minimal mixing and low friction, such as in microfluidics and aerodynamic testing. Turbulent flow, characterized by chaotic fluctuations, enhances mixing and heat transfer, making it suitable for industrial processes like combustion and chemical reactors. Selecting the right flow type depends on balancing the need for precision and efficiency against the benefits of enhanced mixing and energy dissipation.

Laminar flow Infographic

libterm.com

libterm.com