Air-cooled heat exchangers efficiently transfer heat by using ambient air to cool fluids, reducing the need for water and minimizing operational costs. These systems are ideal for industries where water scarcity is a concern or environmental regulations restrict water usage. Explore the full article to understand how your choice of air-cooled heat exchangers can optimize thermal management in your applications.

Table of Comparison

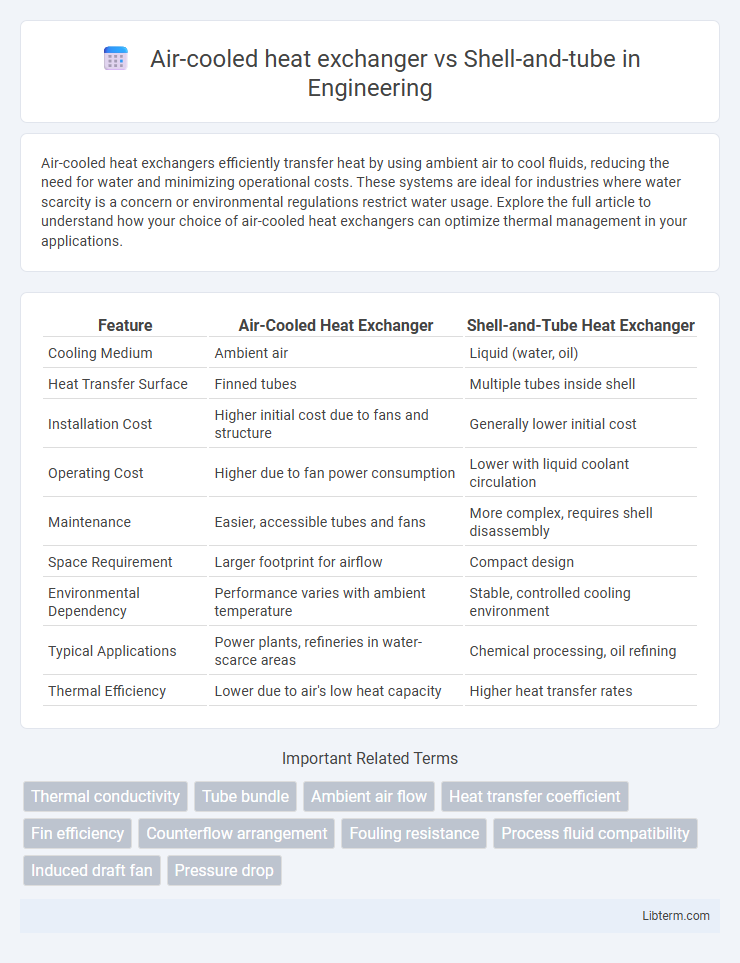

| Feature | Air-Cooled Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Cooling Medium | Ambient air | Liquid (water, oil) |

| Heat Transfer Surface | Finned tubes | Multiple tubes inside shell |

| Installation Cost | Higher initial cost due to fans and structure | Generally lower initial cost |

| Operating Cost | Higher due to fan power consumption | Lower with liquid coolant circulation |

| Maintenance | Easier, accessible tubes and fans | More complex, requires shell disassembly |

| Space Requirement | Larger footprint for airflow | Compact design |

| Environmental Dependency | Performance varies with ambient temperature | Stable, controlled cooling environment |

| Typical Applications | Power plants, refineries in water-scarce areas | Chemical processing, oil refining |

| Thermal Efficiency | Lower due to air's low heat capacity | Higher heat transfer rates |

Introduction to Air-Cooled and Shell-and-Tube Heat Exchangers

Air-cooled heat exchangers utilize ambient air to dissipate heat from industrial fluids, offering energy-efficient cooling without the need for water, ideal for remote or water-scarce locations. Shell-and-tube heat exchangers consist of a series of tubes within a larger shell, enabling effective heat transfer between two fluids with high pressure and temperature differentials, suitable for heavy-duty applications. Both types prioritize thermal efficiency, but selection depends on factors like fluid properties, environmental conditions, and maintenance requirements.

Fundamental Working Principles

Air-cooled heat exchangers operate by transferring heat from a hot fluid to ambient air via finned tubes and fans, relying on convective heat transfer without a need for cooling water. Shell-and-tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, where one fluid flows inside the tubes and another flows outside them, facilitating heat exchange through conduction and convection. The fundamental difference lies in the cooling medium: air versus a secondary fluid, impacting design complexity, efficiency, and application suitability.

Key Design Differences

Air-cooled heat exchangers utilize ambient air to dissipate heat through finned tubes and fans, making them ideal for locations lacking cooling water, whereas shell-and-tube heat exchangers rely on a tube bundle enclosed in a shell that allows one fluid to flow inside the tubes and another fluid over the tubes for heat transfer. The design of air-cooled heat exchangers emphasizes maximizing surface area and airflow efficiency with low maintenance requirements, while shell-and-tube designs focus on pressure containment, cleaning access, and handling high-temperature and high-pressure applications. Material selection, thermal performance, and operational constraints such as fouling resistance and space availability critically influence the choice between these two heat exchanger types.

Efficiency Comparison

Air-cooled heat exchangers offer lower efficiency compared to shell-and-tube designs due to limited heat transfer surface area and reliance on ambient air temperature. Shell-and-tube heat exchangers achieve higher thermal efficiency by maximizing surface contact between fluids and utilizing liquid-to-liquid heat transfer. The efficiency of shell-and-tube units typically ranges from 70% to 90%, whereas air-cooled units often operate around 50% to 70% under similar conditions.

Space and Installation Requirements

Air-cooled heat exchangers demand significantly less space and simpler installation compared to shell-and-tube designs, as they eliminate the need for extensive piping and cooling water infrastructure. Their compact, self-contained structure suits locations with limited footprint and scarce water resources. Shell-and-tube heat exchangers require larger physical space due to the associated coolant circulation system and often involve more complex and time-consuming installation processes.

Maintenance and Operating Costs

Air-cooled heat exchangers have lower operating costs due to the absence of cooling water, reducing expenses related to water treatment and pumping. Maintenance for air-cooled units involves regular cleaning of fins to prevent fouling and ensure efficient heat transfer. Shell-and-tube heat exchangers require more frequent maintenance, including tube cleaning, inspection for leaks, and potential replacement, leading to higher overall maintenance costs.

Performance in Various Environmental Conditions

Air-cooled heat exchangers maintain consistent performance in arid and low-humidity environments by dissipating heat using ambient air, making them ideal for water-scarce regions. Shell-and-tube heat exchangers outperform in high-pressure and high-temperature applications due to their robust design and effective heat transfer efficiency under varying thermal loads. Temperature fluctuations affect air-cooled units more significantly, while shell-and-tube models offer greater stability and reliability across diverse operational conditions.

Safety and Reliability Considerations

Air-cooled heat exchangers offer enhanced safety by minimizing the risk of fluid leakage and fire hazards due to their open-air design, eliminating the need for coolant fluids under high pressure. Shell-and-tube heat exchangers provide robust reliability in high-pressure and high-temperature environments but require rigorous maintenance to prevent tube corrosion, fouling, and potential catastrophic failure. Selecting the appropriate heat exchanger depends on the operational pressure, temperature conditions, and required safety protocols to ensure long-term system integrity and performance.

Typical Industrial Applications

Air-cooled heat exchangers are commonly used in industries with limited water availability, such as power plants, petrochemical refining, and natural gas processing, where ambient air serves as the cooling medium. Shell-and-tube heat exchangers dominate in chemical processing, oil refining, and HVAC systems requiring high-pressure and high-temperature applications with efficient heat transfer using liquid coolants. Both types support critical thermal management, but air-cooled units excel in remote or environmentally sensitive sites, while shell-and-tube configurations are preferred for more controlled industrial conditions with extensive maintenance support.

Selecting the Right Heat Exchanger for Your Needs

Air-cooled heat exchangers provide efficient cooling using ambient air, making them ideal for locations with limited water availability, while shell-and-tube exchangers excel in handling high-pressure and high-temperature applications with superior thermal performance. Selection depends on factors such as operating temperature range, fluid compatibility, maintenance requirements, and installation space constraints. Evaluating these criteria ensures optimal heat transfer efficiency and cost-effectiveness for specific industrial processes.

Air-cooled heat exchanger Infographic

libterm.com

libterm.com